TEST TOOL DEVELOPMENT

When clients partner with Simplexity, they can have confidence in the quality of the designs that are created. Simplexity’s Test Tool Development work extends beyond the design engineering that goes into the product itself. It is often also necessary to develop test tools that can verify product performance and quality from concept to production.

Simplexity engineers have extensive experience designing test tools, process development tools, quality control (QC) tools, and assembly fixtures. These tools may be used by clients, vendors, contract manufacturing partners, or tooling vendors to support the complete product concept-to-production life cycle. Supported technologies often include fluidics, embedded motion, or pneumatics along with integration of a variety of sensors for force, position, temperature, and pressure measurements.

Benefits to Clients

Why is test tool development important? Test tool development offers several critical benefits to customers.

- Minimized Time-to-Market: Efficient validation tools can reduce time-to-market for products.

- Cost Optimization: Identifying and resolving early design issues minimizes costly adjustments during later stages.

- Quality Assurance: QC tools ensure products meet quality standards consistently throughout production.

Some Test Tool Examples Include:

Product Development Test Beds:

- Test tools for prototype characterization, performance validation and technology feasibility assessments.

Manufacturing QC Tools:

- Incoming QC, In-Line QC, and End-Of-Line QC tools for monitoring product quality throughout production.

Client-Enabled Manufacturing Oversight Tools:

- Client-owned production test database customizable for real-time manufacturing quality audits.

Product Development Test Beds

Simplexity engineers leverage characterization tools to ensure product concepts are feasible.

During Phase 2A of Architecture and Technology Feasibility, characterization test tools assess various elements of the design to confirm product architecture choices BEFORE detailed prototype development begins. Characterization testing informs product decisions and can examine specific performance metrics early on when design corrections or adjustments are less costly to make. Sometimes requirements aren’t fully defined at the outset. Characterization testing helps determine the product's full capability range to inform and refine product requirements. That data can then be used to set the product requirement. Other times, experiments test the product's workflow to determine the best path forward (the product should lift A first, then rotate B, then inflate C, etc.).

Process tools confirm that a suggested process will yield optimal results well before other process-related costs are incurred. Research tools enable the simulation of theoretical development options in a test environment to confirm expected outcomes early on.

Throughout the product development process, Simplexity can create additional test tools to confirm prototype performance and technology feasibility assumptions. These tests provide real-time validation of design choices during critical product development iterations.

Manufacturing QC Tools

Simplexity builds incoming QC, in-line QC, and end-of-line QC test tools which are leveraged to monitor product quality in production. Simplexity engineers will supply product manuals, train contract manufacturing staff, and offer remote support to manage Manufacturing Test Equipment (MTE) hand-offs.

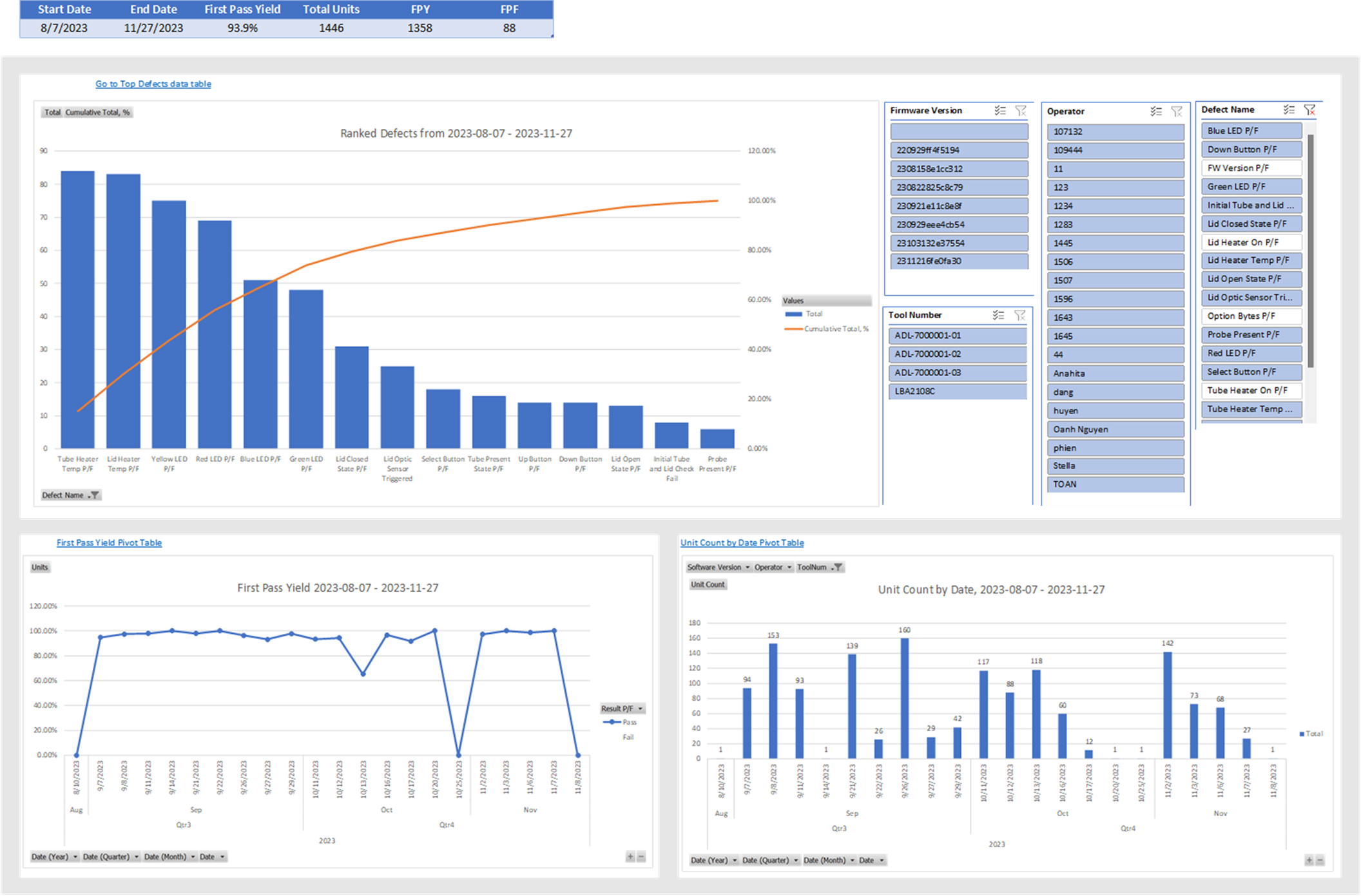

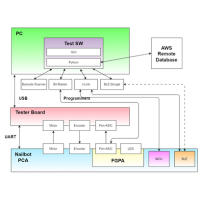

Client-Enabled Manufacturing Oversight

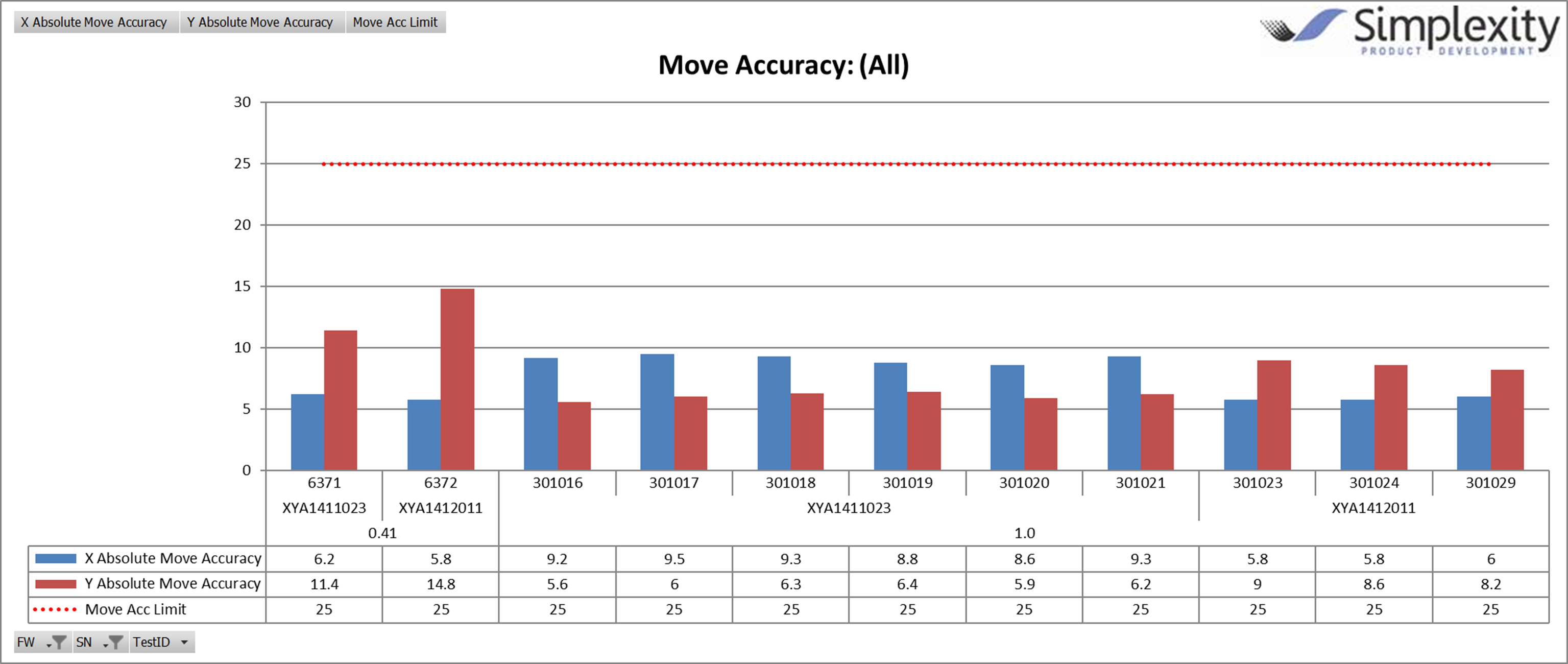

Clients can access a Simplexity-designed application that automates the upload of manufacturing test results to a database in real-time. This allows clients to monitor quality and troubleshoot issues and enables oversight for ongoing monitoring of contract manufacturing quality. Customizable charts pull data from a SQL database in real time. Client team members can log in and review test results at any time. The client can also customize reports from provided data as needed to fit their specific needs.

Summary

By leveraging Simplexity's expertise in test tool development, clients can ensure solid product conception, design integrity, and manufacturability. This results in optimized time-to-market, reduced manufacturing costs, and enhanced product quality across all stages of development and production. This also ensures clients end up with product designs that can be built cost-effectively, repeatably, and safely at scale to the specifications they require.

Characterization / Product Development Test Bed Examples:

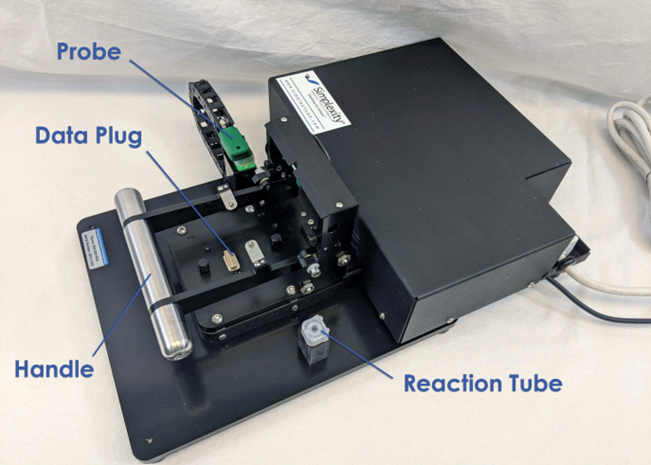

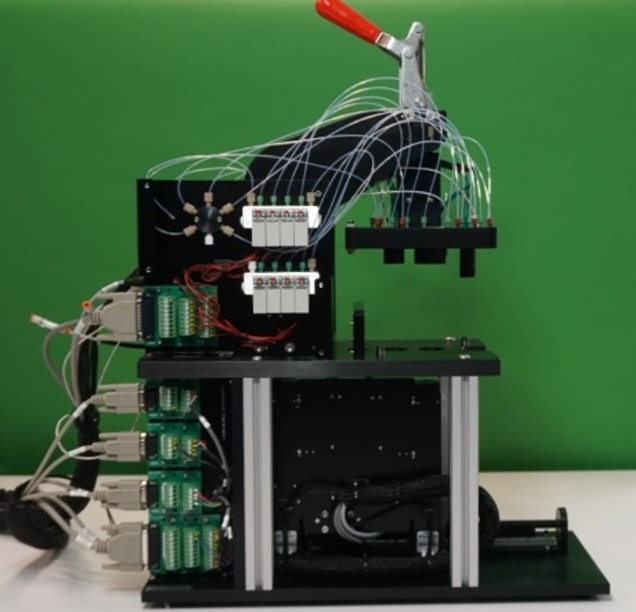

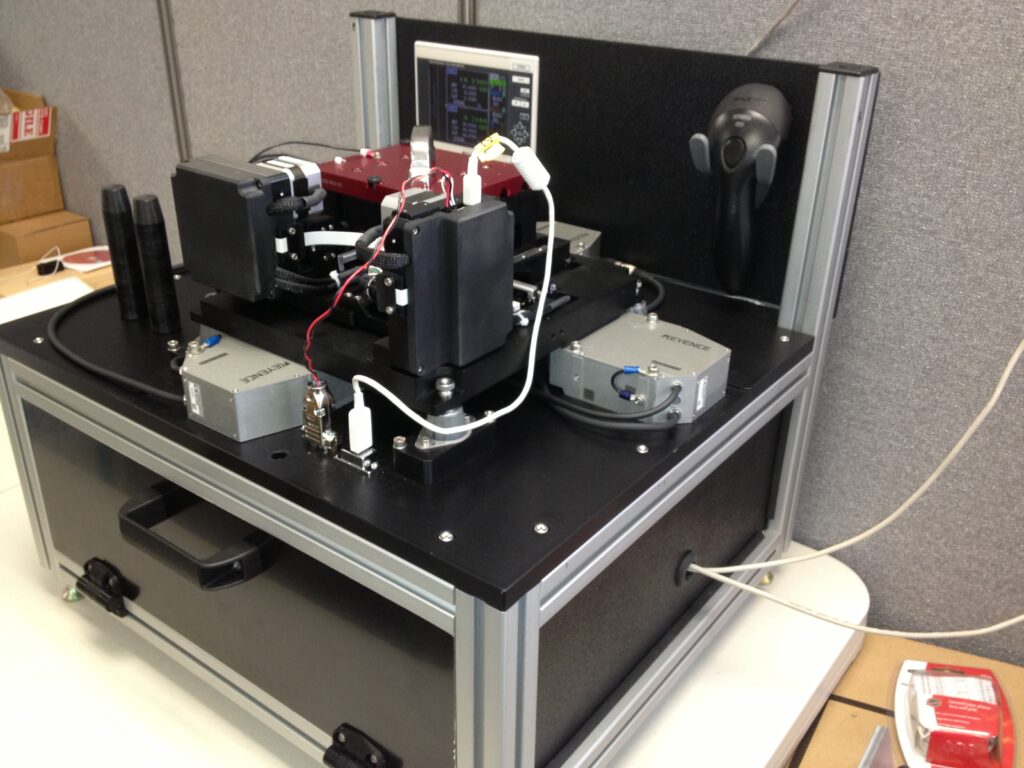

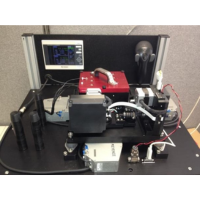

HARDWARE BASED FIRMWARE TEST RIG

HARDWARE BASED FIRMWARE TEST RIG

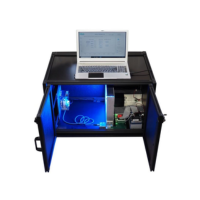

LIBRARY PREPARATION SYSTEM BREADBOARD

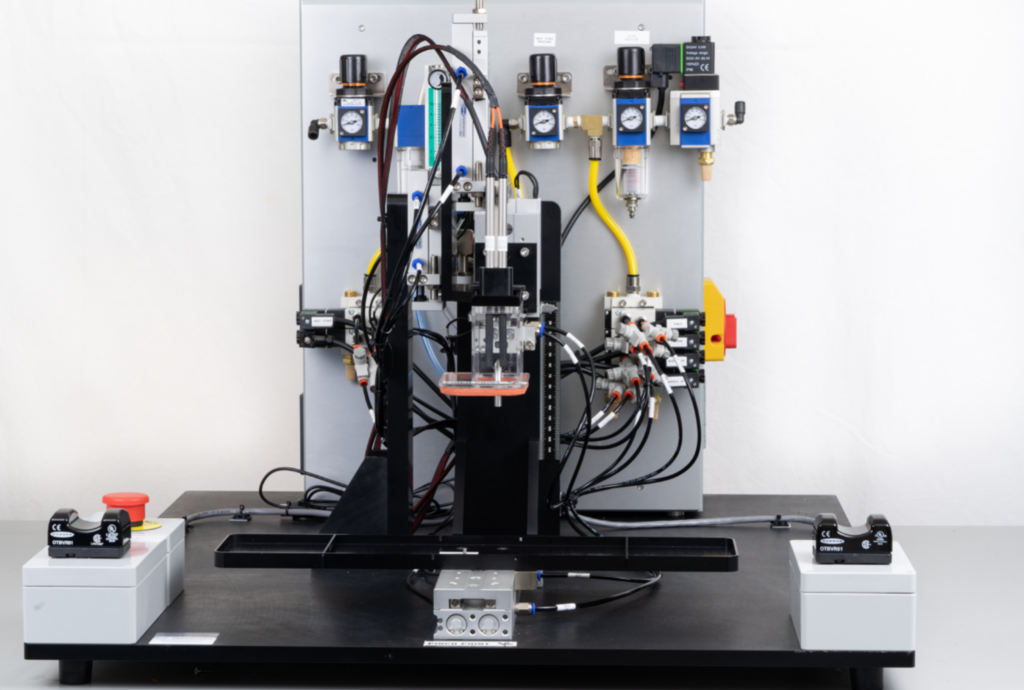

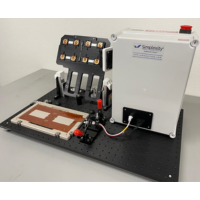

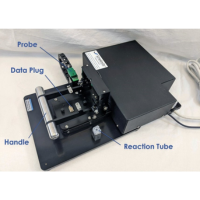

Production / Manufacturing QC Tools Examples:

Manufacturing Oversight Examples:

END OF LINE TEST TOOL FOR X-Y STAGES