Systems Engineering

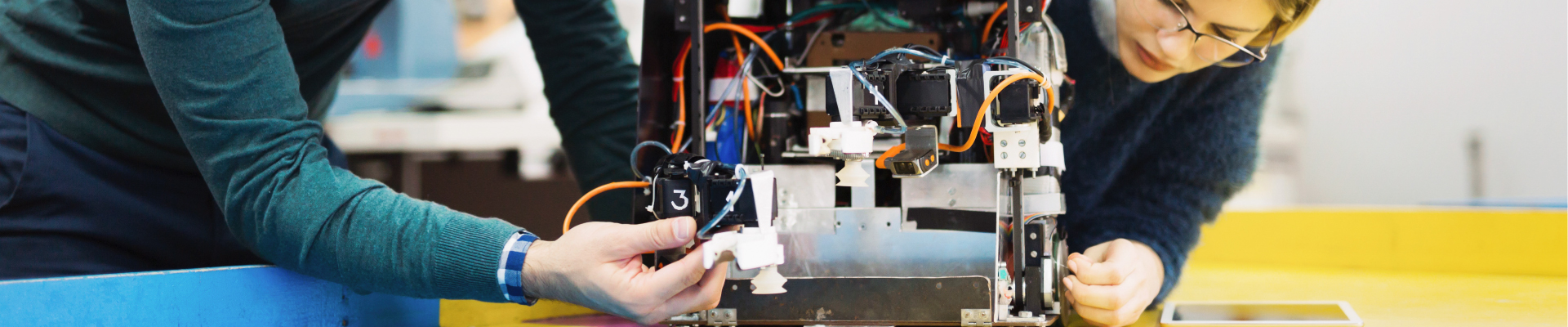

Modern smart devices, whether consumer, medical, or industrial, are complex systems that encompass diverse technologies. These devices typically require a combination of precision mechanics, electronics, microprocessors and algorithms. Each of these pieces requires a depth of expertise for delivery.

While many companies have someone that attempts to fulfill the role of a systems engineer in addition to their duties as a senior engineer in another discipline, Simplexity employs dedicated systems engineering experts with deep experience in motion controls and automation.

Simplexity’s Systems-level Engineering Process Includes:

- Requirements gathering and analysis. Device features and performance, cost targets, safety, and user interactions all must be considered at the system level. Analysis of the system requirements then informs project phasing and team/discipline involvement.

- System architecture. From mechanics, actuators, sensors, electronics, microprocessors, communication protocols, and algorithms, the high-level architecture requires attention early in the product design cycle. Combined, Simplexity’s systems engineering team has over 10 decades of design experience delivering complex electromechanical systems to a variety of industries.

- Cross-disciplinary system optimization. Interactions between system parameters are often complex and non-intuitive. The cost associated with optimization with hardware prototypes can be significant and likely far from the true optimal design. In-depth motion control and simulation expertise allows the systems engineering team to optimize cost/performance tradeoffs using our custom analysis tools, making informed decisions about component selection and configuration in a very efficient manner. We’re routinely able to reduce customers’ Bill-of-Materials (BOM) cost of the motion system considerably.

- Product test and verification. Simplexity’s systems engineering works with quality engineering to outline testing strategies for both subsystems and components as well as the entire system, including pre-test on functional prototypes, to ensure that the product meets requirements.

Systems Engineering Approach

A core aspect of Simplexity’s product development process is to “brainstorm from a systems perspective.” While modern smart products are built from components made of materials such as plastic, metal, and composites, they are much more than the sum of their parts. By focusing on critical features of the design that cut across the traditional disciplinary lines, our systems engineering experts catch the issues that tend to fall through the cracks with engineering teams organized in the traditional manner.

Time and time again, an experienced systems engineer can achieve performance and cost optimizations that other teams simply cannot match. In fact, clients have repeatedly come to us to fix faulty designs that traditionally organized engineering firms have created. It is this careful and successful integration of mechatronics – combined mechanics, electronics, software and algorithms – brought together by a multi-disciplinary engineering team, that brings a product to life. At Simplexity, the systems engineering team ties together the pieces from various technologies into a holistic product.

Simplexity’s Mechatronic System Engineering Expertise Includes:

- Mechatronic System Architecture. From actuators/sensors to processors/communication protocols and power supplies, the high-level mechatronic architecture requires attention early in the product design cycle.

- Cross-Discipline Specification. Frequently, high level product specifications tie together sub-specs across disciplines and physical domains. Systems engineering identifies and optimizes the design with an understanding of how the multitude of specifications ‘fits together’ to deliver the desired performance.

- Dynamic Simulation. Experimental evaluation of system components can be time/cost prohibitive. Simulation via lumped-parameter, closed-form methods or numerical, discrete-time techniques can help streamline the effort by trimming the design space without the cost or lead times associated with procuring test hardware.

- Motion Control System Optimization. Interactions between control system parameters are often complex and non-linear. The cost associated with optimization can be significant. In-depth commercial motion control expertise allows the systems engineering team to optimize along the cost/performance tradeoff with the best components to deliver the performance your system needs at the minimum possible cost, especially in high volume.

- Embedded Control Algorithms. Experience designing and delivering feedback control systems across a variety of industrial applications including medical, industrial, and consumer products. System characterization, controller design, state estimation/Kalman Filtering, and digital signal processing (DSP) are examples of Simplexity’s algorithmic toolbox.

- Data Analysis and Machine Learning. Experience processing and analyzing simulated or experimental datasets with statistical and machine learning techniques, primarily using Python.

- Rapid Prototyping of Automatic Control Systems. Proof of concept demonstrations offer near term/viability. Simplexity’s systems engineering team can design a ‘works like’ system using COTS hardware and flexible electronics/processors to evaluate a given system architecture and in the early phases of the product design.

Simplexity's Engineering Experience

Simplexity’s engineering team is made up of engineers with advanced degrees from top universities in fields such as digital signal processing and feedback control systems. Our expertise also includes practical knowledge based on years of product development experience.

This mix of knowledge and experience allows us to solve the most difficult problems for our customers, which is why product companies and engineering service providers have sought out Simplexity. We look forward to bringing the power of a systems engineering approach to your product.

“Simplexity has a highly motivated, technically resourceful staff. For a complete project or for augmentation of an existing program, they are a go-to team in a crunch.”

“Simplexity has a highly motivated, technically resourceful staff. For a complete project or for augmentation of an existing program, they are a go-to team in a crunch.”

-Taylor Reid

Director Instrumentation, Agilent Technologies