ROBOTICS AND AUTOMATION PRODUCT DEVELOPMENT

Simplexity’s expertise in robotics and automation product development centers around customization and development of custom subsystems and components for robotic systems. If you have a challenging application where standard off-the-shelf components are insufficient, we can design custom or semi-custom solutions to meet specific needs. Simplexity has expertise in integrating various types of robot arms, designing custom end effectors, and developing autonomous mobile robots (AMRs). Capabilities extend to custom drive systems, mechanisms, gear trains, kinematic analysis, robot motion, controls, algorithms, motor optimization, embedded firmware, high-speed camera and sensor interfaces, electronics, and PCBA design. Clients have partnered with Simplexity to develop/improve early concept prototypes to gain investor and customer buy-in for small-volume projects. Clients also benefit from Simplexity’s experience in designing products for high-volume manufacturing to receive cost-effective and reliable robotic solutions at scale.

SIMPLEXITY SKILL SETS RELEVANT FOR ROBOTICS AND AUTOMATION PRODUCT DEVELOPMENT

Whether your project requires a brand-new design or optimization of an existing design, we are happy to discuss your needs and customize a solution to help you succeed. We can leverage decades of experience in robotics and automation product development, including skill areas such as:

Mechanism and Mechanical Design

- End-effector design

- Design of custom drive systems and custom gear trains

- Design for manufacturing and assembly, DFMA

- Design for reliability, testability, usability, and manufacturability

Robot Motion, Control & Algorithms

- Kinematic analysis

- Path planning and optimization

- Workflow analysis and task scheduling optimization

- Motor and actuator selection, design and optimization

- Linear and nonlinear feedback control algorithm development

- Embedded firmware architecture and detail design

- Codesys application programming for system level control

- EtherCAT (Ethernet for Control Automation Technology)

Electrical Design

- Custom printed circuit board assembly (PCBA) design

- Motor drive electronics

- Sensor interfaces and integration including analog front end

- High speed camera interfaces

Integration of Commercial Off the Shelf (COTS) Components Such As:

- Industrial robots

- Smart motors

- PLC’s

FEATURED ROBOTICS AND AUTOMATION PRODUCT DEVELOPMENT CASE STUDIES

THE PROBLEM

Errors and time to translate construction drawings onto a construction site.

Current method is to use chalk to draw the plans onto the construction floor.

THE SOLUTION

- An Autonomous Mobile Robot (AMR) capable of printing full-scale construction drawings directly onto slabs with 1/16-inch accuracy

- Reduces total layout time from months to days while streamlining construction processes, and reducing errors across multiple sites

- Print all trades’ layout at once to compress the overall schedule

- Robotic field printer autonomously prints CAD or CSV data directly onto the construction floor

Read the full Dusty Robotics case study and watch the future of construction layout in action with the Dusty Robotics FieldPrint Robot.

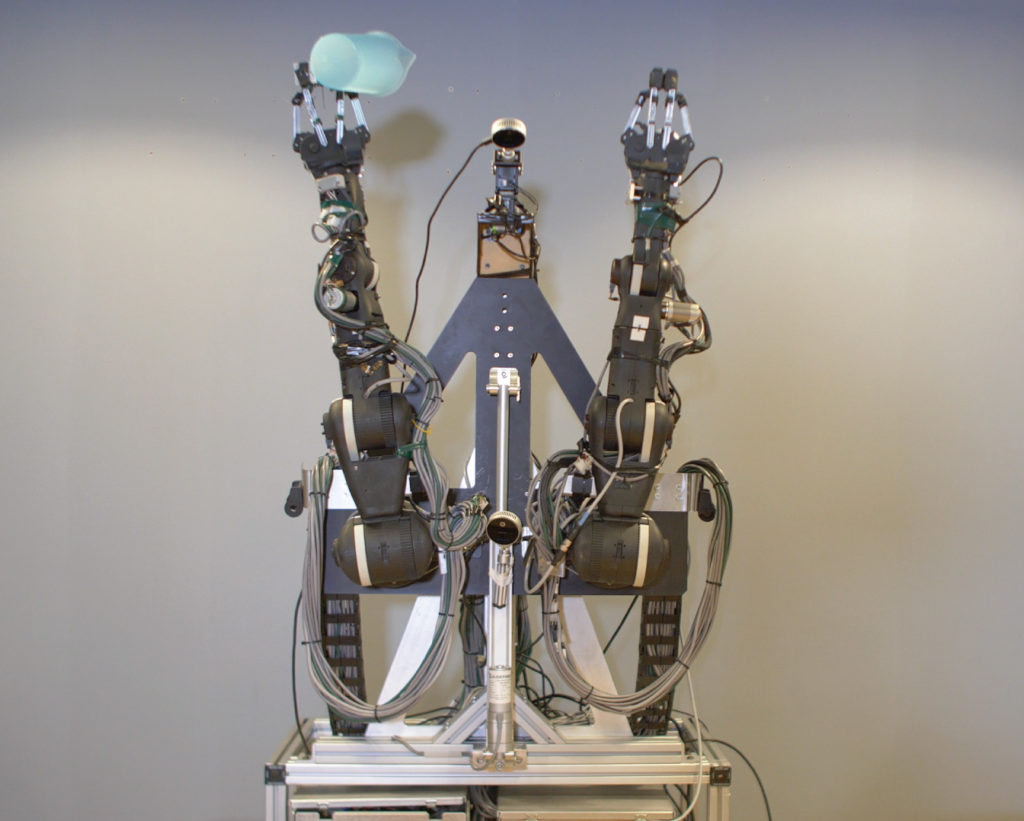

THE PROBLEM

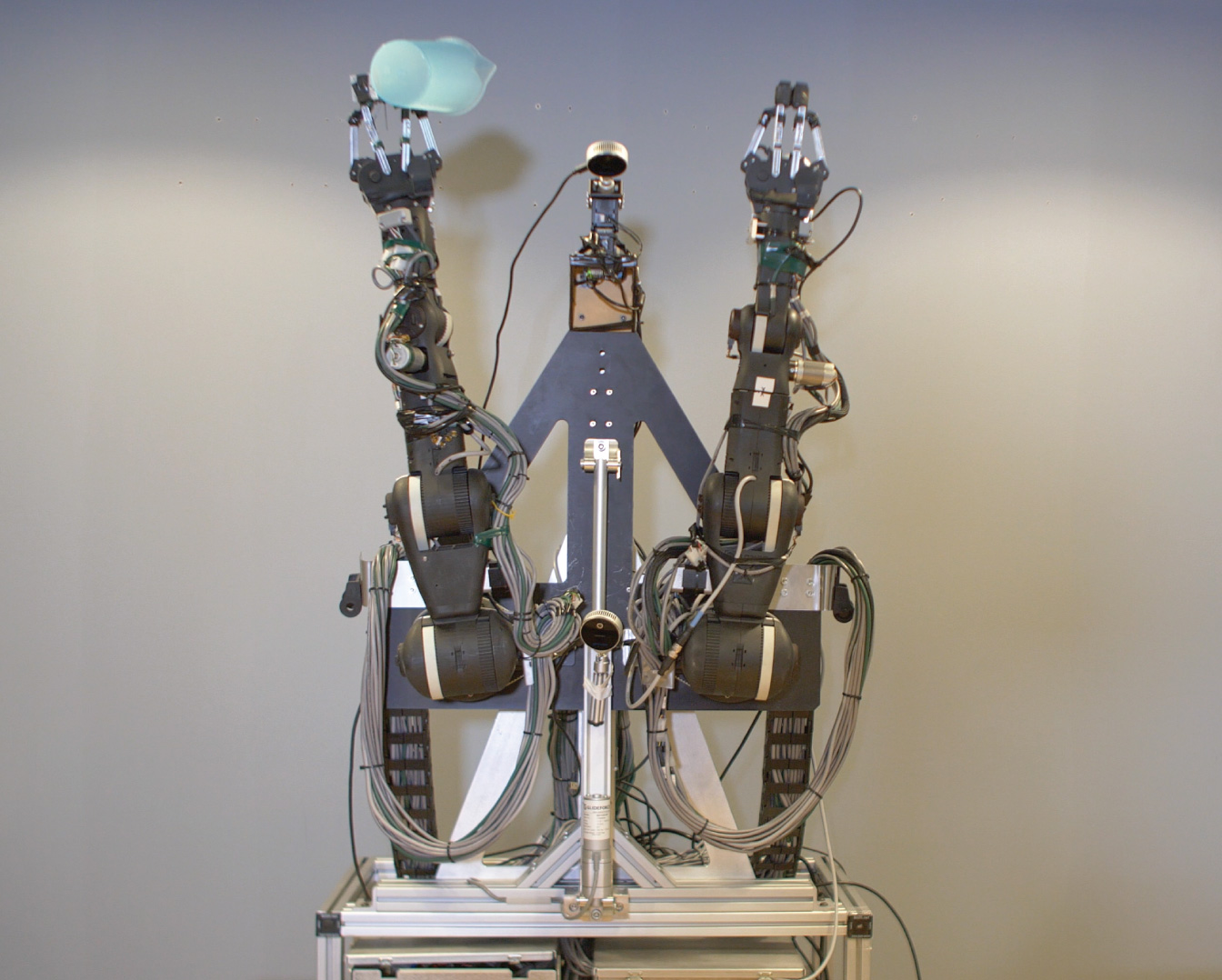

A software and AI company needed a custom robot that would mimic what a human does.

It would be a demo unit to show how the robot can learn new skills by listening to spoken instructions and watching humans.

THE SOLUTION

Custom-designed robot with:

- Two 6-degree of freedom arms

- A motorized gimbal that pitched and yawed a vision system

- Z-Lift mechanism for lifting the arms and vision system

- Custom grippers

- On a mobile base

Read the full AiVot general-purpose and fast learning robot case study and watch the full-length video. Watch additional videos and use cases of the robot used for logistics, hospitality, and food preparation.

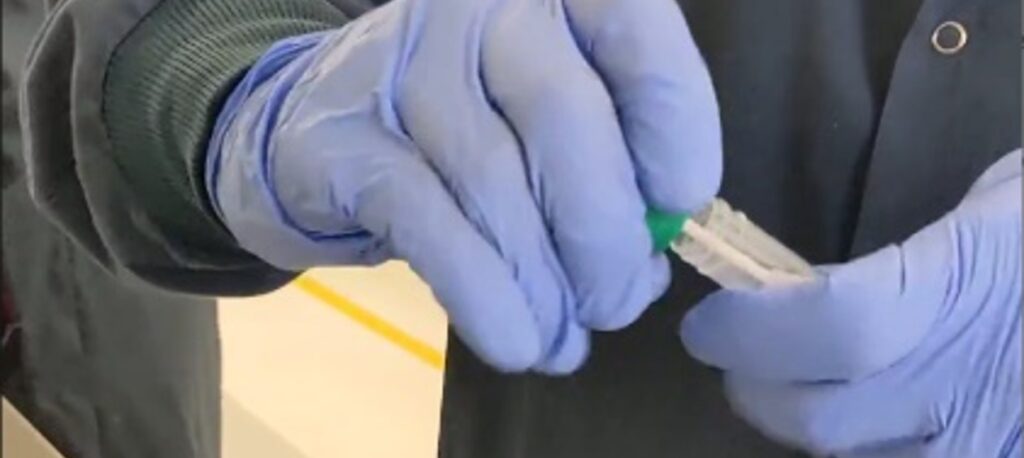

THE PROBLEM

Human operators at a Biotech company risked repetitive motion injury from uncapping and extracting DNA swab samples from tubes by hand

THE SOLUTION

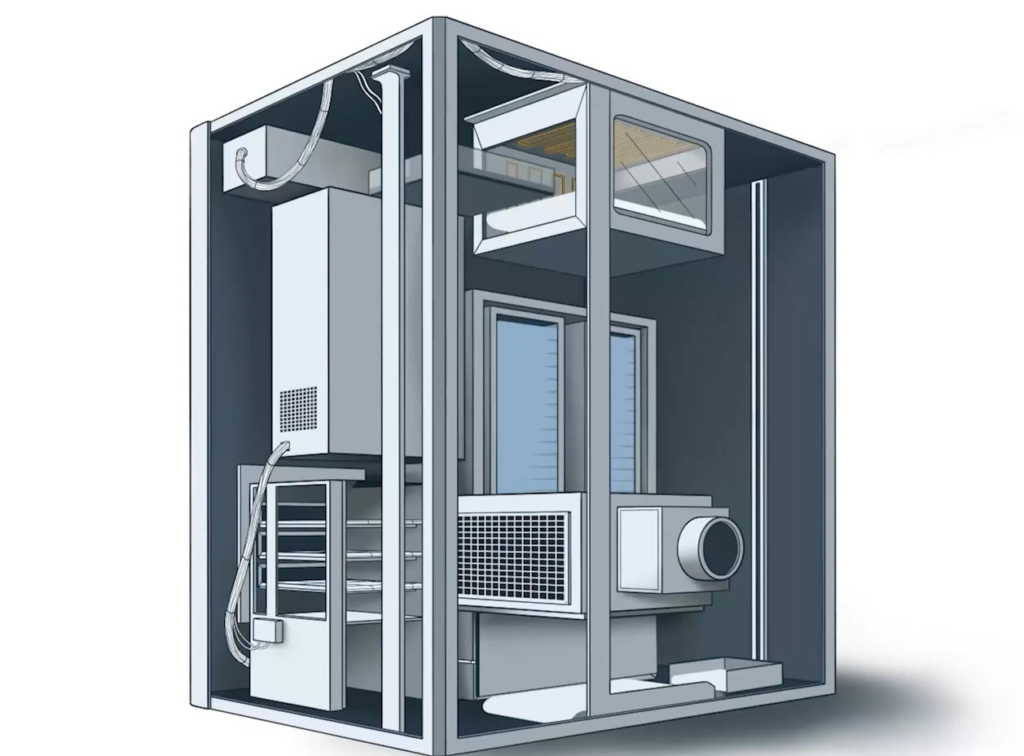

Automated DNA sample extraction robotic system

- 4 custom designed sample extraction stations

- Pick and place robot to service each station

- Self-contained safety enclosure on modified rolling lab bench

Read the full Automated DNA Sample Extraction Robotic System case study and watch the full-length video. Watch the robot in action as it uncaps the vials, extracts DNA, discards the processed swab, and delivers the opened vials to an output tray with their barcodes aligned towards the user.

THE PROBLEM

Critical system failures in a food automation vending machine prototype

- 10 different mechanical sub-systems to move trays holding the food items

- Controlled by 2 microprocessors real-time

- Never successfully delivered a full load of trays

THE SOLUTION

- Root cause analysis on each critical defect

- A complete rewrite of the real-time firmware

- Remapped motors and sensors to the microcontrollers

- Redesign of a critical tray handoff mechanism

- Simplexity's redesigned system delivered the first full load of trays within 6 weeks from design start

Read the full Food Automation Vending Machine case study and watch the full-length animation.

From complex robotic handling systems to custom kiosks, Simplexity has the capabilities and experience to help you design your robotic product. Through our internal prototyping capabilities, NPI team, and contract manufacturing partners, we help guide your design through production and successful deployment on the factory floor, laboratory, or retail space.

“I’d highly recommend Simplexity to a friend. They have good expertise in what they do, they’re great partners, and they deliver projects on time, within budget, and with great results.”

- Shashwat Srivastav, Founder and CEO, Aivot

ADDITIONAL ROBOTICS-RELATED RESOURCES

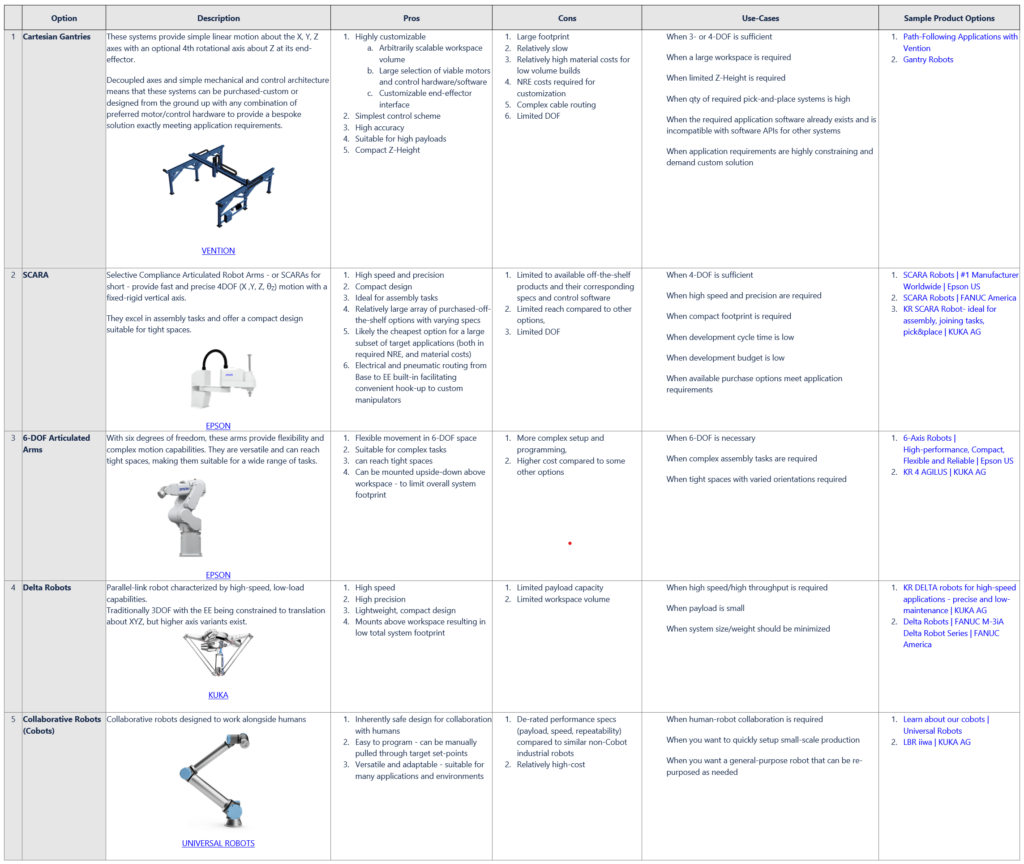

Whitepaper: A Comprehensive Guide to Pick-and-Place Robots and Systems

The world of robotics makes automation of routine and repetitive tasks more accessible than ever. Yet with the myriad of options, selecting the best pick-and-place robot for your application can be a daunting and time-consuming endeavor. Now there’s a shortcut!

In Simplexity’s whitepaper, "A Comprehensive Guide to Pick-and-Place Robots and Systems", Senior Systems Engineer, Lewis Siempelkamp, provides an in-depth overview of pick and place systems, exploring their functionalities, key application requirements, and design considerations to help you select the right solution for your needs.

Read the Whitepaper and check out the Selection Guidance Table

Whitepaper: Maximizing Robotics Performance

Are you developing a robotic or automated product where throughput and cycle time influence how successful it will be relative to the competition? If it’s a process with many interdependent steps and operations, having a systematic method for optimizing task scheduling can save you development time and cost.

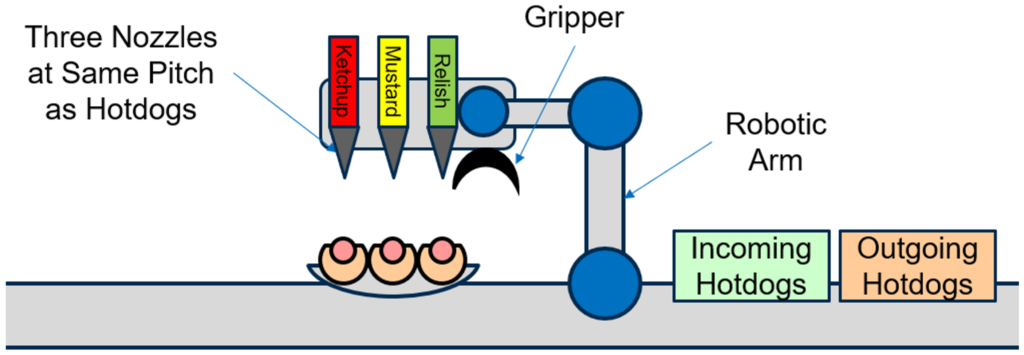

Example of a system using three independent dispense nozzles

Read Simplexity’s whitepaper, "Maximizing Robotics Performance: Task Scheduling Techniques, Modeling, and Efficient Resource Management", where Neil starts with simple examples and concludes with equations and calculus to help you evaluate the sensitivity of parameters for timing models.

YOU MAY ALSO LIKE:

PROUD MEMBERS OF:

View Robotics and Automation Case Studies

Dusty Robotics

Dusty Robotics

Learn More

IUNU ROBOTIC VINE PLANT MONITOR

IUNU ROBOTIC VINE PLANT MONITOR

Learn More

Automated DNA Sample Extraction Robot

Automated DNA Sample Extraction Robot

Learn More

AIVOT

AIVOT

Learn More