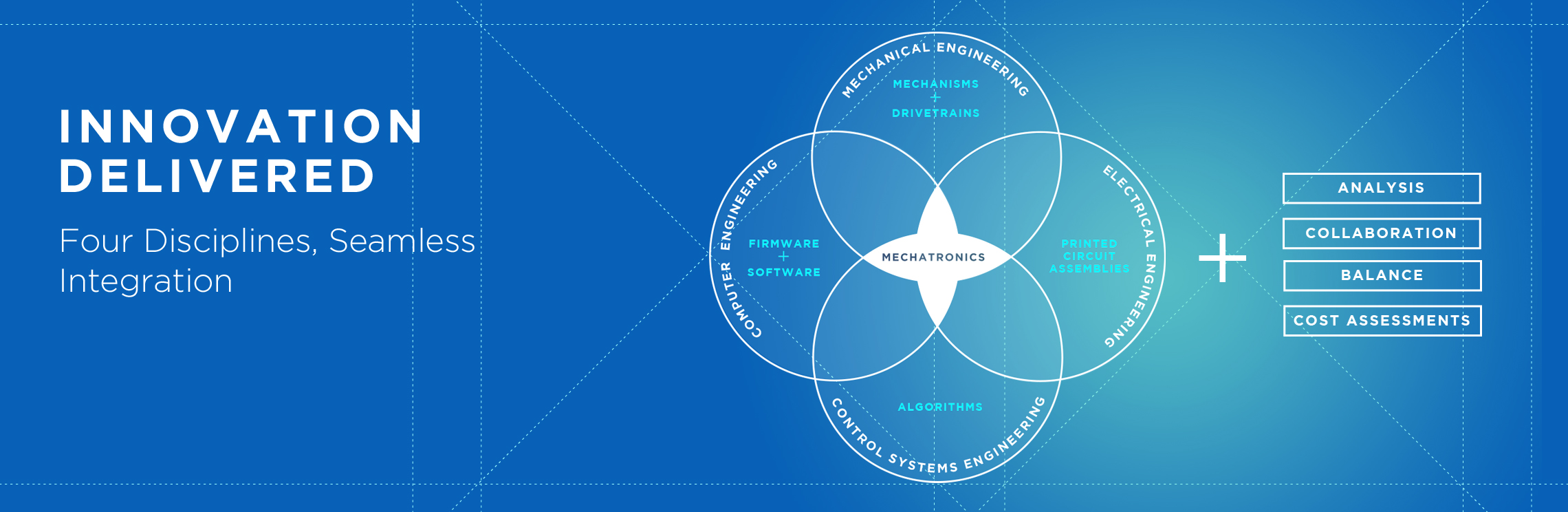

Mechatronics

Designing electro-mechanical products and machines, especially ones that require precise motion, is a cross disciplinary endeavor requiring advanced skills in mechanical, electrical, computer, and controls engineering. This mix of skills has come to be known as "mechatronics.” The Venn diagram above shows how these four different disciplines overlap to create the field of mechatronics.

Most companies that specialize in mechatronics, automation, or controls do so from an industrial automation standpoint. These companies integrate off-the-shelf industrial components into a solution. This is definitely the way to go if you are building one, or a few products or machines.

However, when designing a product that will be built in volumes ranging from many hundreds to hundreds of thousands or more, using off-the-shelf components is simply not cost competitive. Product development firms like Simplexity understand production processes and design techniques that deliver the best cost to performance ratios for mid- to high-volume product design.

The overlap between mechatronics and product development can best be described by the phrase “Embedded Motion.” Things like a television require expert product development, but have no moving parts and are not considered mechatronic products.There are also mechatronic solutions, like factory automation, that fall outside of the “product” space. At the intersection of these spaces are those products that have motion embedded in their hearts, and that is where Simplexity operates.

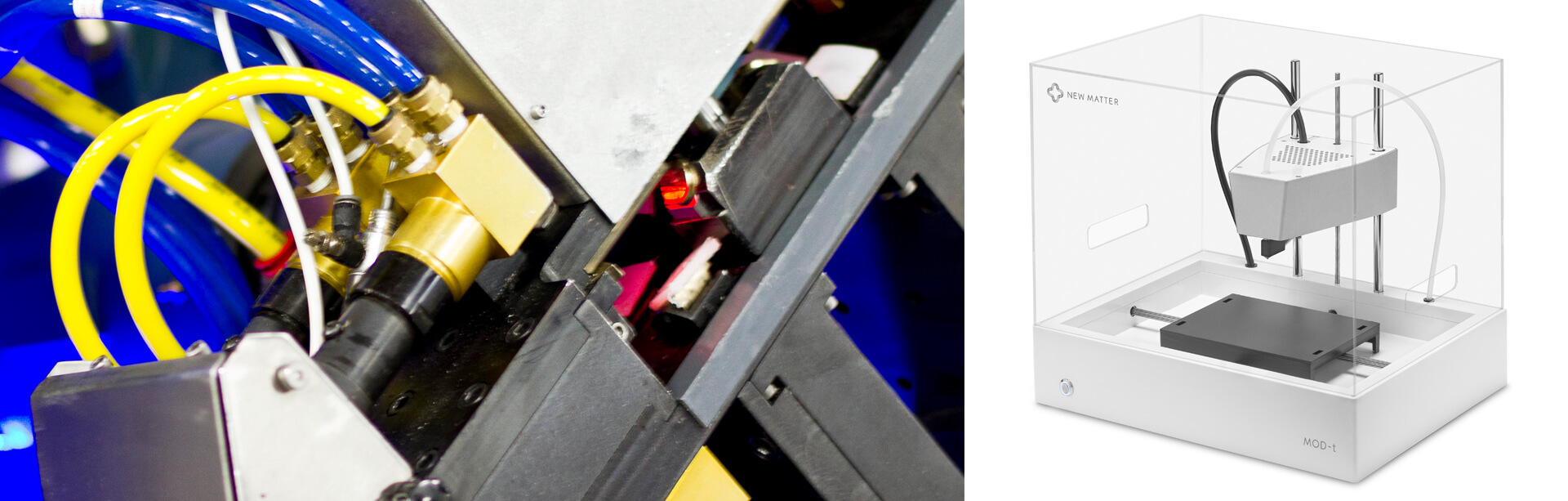

“One of the great things about Simplexity is that their expertise is fairly wide ranging throughout the product development process.”

- STEVE SCHELL

CEO AND CO-FOUNDER, NEW MATTER

Simplexity Focuses on Mechatronics for the Development of Mid-to-High Volume Products

For products with a low volume and a high component cost (top left of the diagram above), designers typically need to rely on motion system resellers and integrators to specify and integrate commercial, off-the-shelf components into a custom industrial solution. At the bottom left of the diagram is the hobbyist or maker market, where people strive to make low volume products with low cost components like Arduino or Raspberry Pi. The top right of the diagram shows custom industrial products, like cars and construction equipment that use higher cost motion components.

The bottom right of the diagram shows the types of products that are considered embedded motion products. Since product volumes are higher, relying on the same motion system components and integrators as the top left of the diagram will yield products that are not cost competitive. In this space, highly experienced mechatronic engineers are vital. Without the cross-disciplinary skillset that mechatronic engineers provide, motion systems are typically overdesigned in each individual design subsystem. With a true cross-disciplinary team, new tradeoffs become available which can yield an overall better design.

Historically, Simplexity has found that teams without a dedicated mechatronics system engineer typically significantly overdesign, adding as much 2x the required cost to the system. Since many of our engineers have decades of experience designing HP’s high volume ink-jet printers, they have learned the secrets of designing motion systems with best-in-class cost to performance ratios. With a systems approach and sufficient characterization, design margin can be balanced across the system components so that no component is overdesigned. That optimization in margin can yield a huge reduction in total cost for higher production volume.

Want to learn more about mechatronics?

Check out CTO, Doug Harriman as he chats with Embedded FM about motors, controllers, and designing mechatronic systems in the full podcast episode 332: There Were Fires.