QUALITY AND REGULATORY

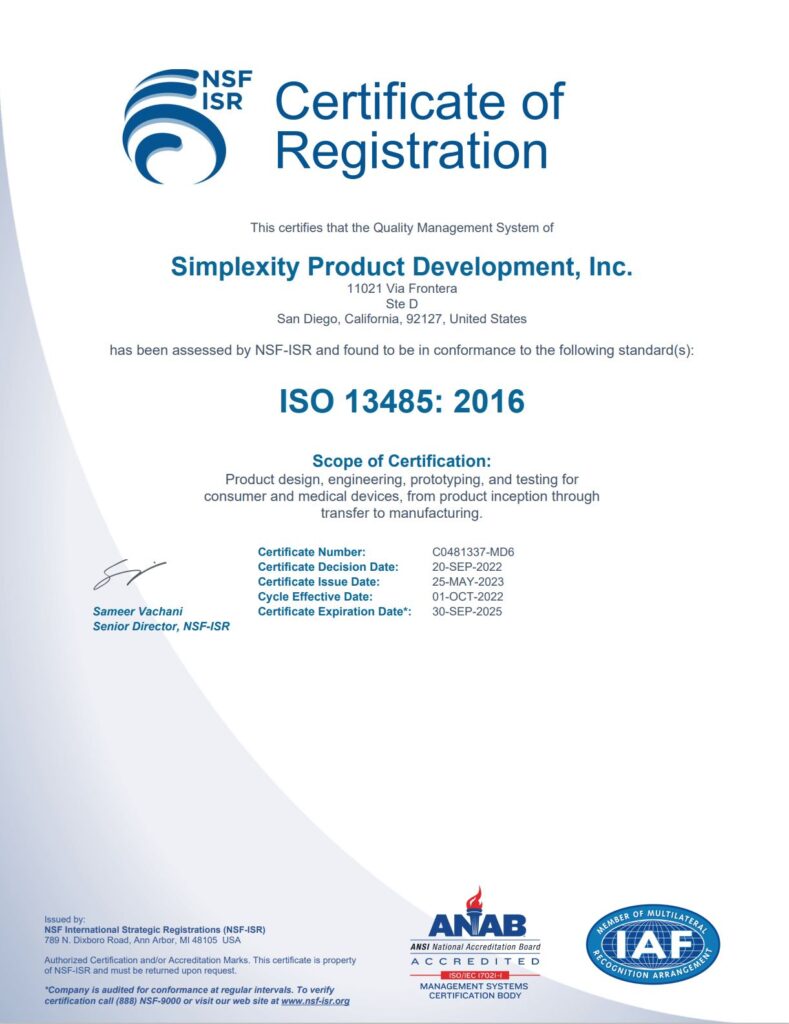

We support clients through every phase of medical device design and development — from proof-of-concept to next-generation products – and our ISO 13485:2016 certified compliant quality management system ensures consistent design and development of devices that are safe for their intended use.

Simplexity uses a validated and 21 CFR part 11 compliant quality management software system for project and process documentation. This software includes a web portal that provides our clients direct access to their documentation, and our processes can be used stand-alone or in conjunction with a client’s quality management system.

In addition to ISO 13485, our team is knowledgeable in multiple standards that apply to medical devices, including IEC 62304, ISO 14971, IEC 60601, and IEC 61010. We work with our clients to identify the appropriate standards and required safety agency testing for their products.

We also work with our clients to evaluate and select the right ISO 13485 certified contract manufacturer, if required. We then work closely with the manufacturer to ensure a smooth and comprehensive design transfer for pre-production device builds and design verification testing.

MEDICAL DEVICE DEVELOPMENT CAPABILITIES AND EXPERTISE

- Medical device design and development to meet requirements for user needs, reliability, manufacturability, and performance

- Redesign of cleared or approved medical devices to improve manufacturability, reduce cost, or replace obsolete components

- Generation of design history file (DHF) documentation to fulfill regulatory submission requirements

- Identification and management of risk throughout the product development process

- Controlled builds of pre-production devices for design verification and usability studies

- Design verification testing

- Supplier evaluation and selection

- Design transfer to contract manufacturers