Case Study:

HP ENVY Zero-Gravity Printer for use in the ISS

The Challenge

Astronauts aboard the International Space Station (ISS) have been printing with almost 20-year-old technology and were ready for an upgrade. Paper printing is still a critical function aboard the ISS since all mission-critical documents need a paper copy and an estimated 1,000 pages per month are printed aboard the ISS. NASA chose HP technology as the next generation of printers for the ISS, specifically the HP OfficeJet 5740. HP selected Simplexity as their engineering partner to work with them to convert the OfficeJet 5740 into a printer capable of printing in zero-gravity.

Original HP OfficeJet 5740 Printer (photo credit HP Inc.)

The main concerns with converting the printer to function without gravity were:

- Paper handling (paper feeding and printed page output)

- Handling the waste ink (due to standard pen servicing routines)

- Mounting of the printer to the ISS

- Print quality

Very early on, it was determined that the actual printing from ink cartridges to paper would not pose a problem in zero-gravity. This is because HP thermal inkjet technology uses thermal excitation to expel tiny droplets of ink about 3 picolitres in volume (1 tablespoon equates to about 15 billion picolitres). Therefore, gravity has insignificant effects on print quality due solely to the cartridge print head. To verify, Simplexity and HP separately ran negative gravity print tests, by printing upside down. The results proved the ink cartridges themselves are not an impediment to zero-gravity printing.

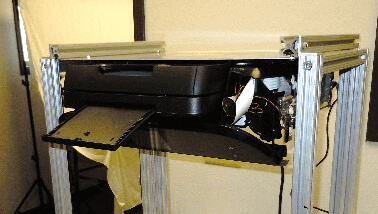

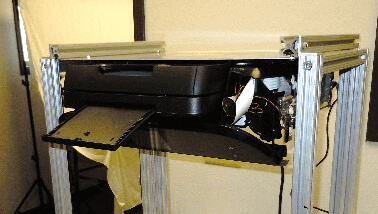

Printer mounted upside down to confirm that print cartridges and paper handling would function correctly in zero-gravity

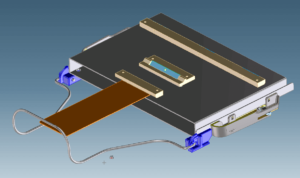

Computer Aided Design (CAD) of sheet metal output tray

Prototype of sheet metal output tray

Dis-assembled MJF 3D printed

output tray (photo credit HP Inc.)

Paper Handling: Containment Of Printer Output

The standard output paper tray on the HP OfficeJet 5740 is open, which could allow the paper to float away after printing in zero-gravity. Thus, a new paper tray needed to be designed that would capture the output. Initially, a sheet-metal tray with a cover was designed to hold the paper.

Then, HP converted the design entirely to MJF. The advantage of switching to MJF 3D printed parts was a significant reduction in unique part count, including the elimination of 18 mechanical fasteners, impossible with conventional sheet metal. Simplexity performed post conversion refinements to help enable the final MJF design.

Though HP had previously developed a hinged bail concept for a multifunction product, Simplexity leveraged this concept and designed a hinged bail with a curved lip to capture media during ejections, especially in fast print modes, through extensive print testing to determine the proper shape and orientation. The bail design was later converted to MJF.

The Process And Solution

Simplexity helped solve the challenges posed by dedicating one of the most printer-experienced teams, with cumulative combined printer-experience exceeding 50 years. In Simplexity engineers, who had prior involvement with the design and development of the original HP OfficeJet 5740 printer, HP found the experienced team to minimize risk and design cycles.

Results

The highest risk area was the inability to verify the engineering design in zero-gravity conditions during product development. While we ran print tests in various printer orientations, including upside down, any paper feed error or paper jam could behave differently in an actual zero-gravity environment. The Simplexity and HP team had one chance at passing product validation through a pre-planned zero-gravity flight test at the end of the development phase, where an airplane flies parabolically at high altitude, representing about 20-seconds of zero-gravity conditions during fast descents.

HP Envy ISS Printer (photo credit HP Inc.)

The test was successful! Through months of careful planning, anticipation, testing and working with the HP team, all the design changes were validated successfully during the first zero-gravity flight test. Simplexity was also chosen by HP to assemble and deliver all 50 flight-ready printers to NASA. While only 2 printers are on the ISS for printing, the others are built at the same time to have replacements for years to come.

The final printer is called the HP Envy ISS. Simplexity is honored to be selected as HP’s engineering partner to help deliver HP’s first ever space-ready printer.

Very early on, it was determined that the actual printing from ink cartridges to paper would not pose a problem in zero-gravity. This is because HP thermal inkjet technology uses thermal excitation to expel tiny droplets of ink about 3 picolitres in volume (1 tablespoon equates to about 15 billion picolitres). Therefore, gravity has insignificant effects on print quality due solely to the cartridge print head. To verify, Simplexity and HP separately ran negative gravity print tests, by printing upside down. The results proved the ink cartridges themselves are not an impediment to zero-gravity printing.

Printer mounted upside down to confirm that print cartridges and paper handling would function correctly in zero-gravity

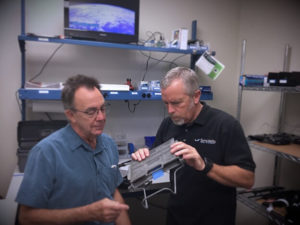

Simplexity Technical Team reviewing the output tray assembly.

Simplexity Technician assembling ink absorbers into the HP ENVY ISS Printer. The added absorbers are designed to capture ink in the zero-gravity environment.

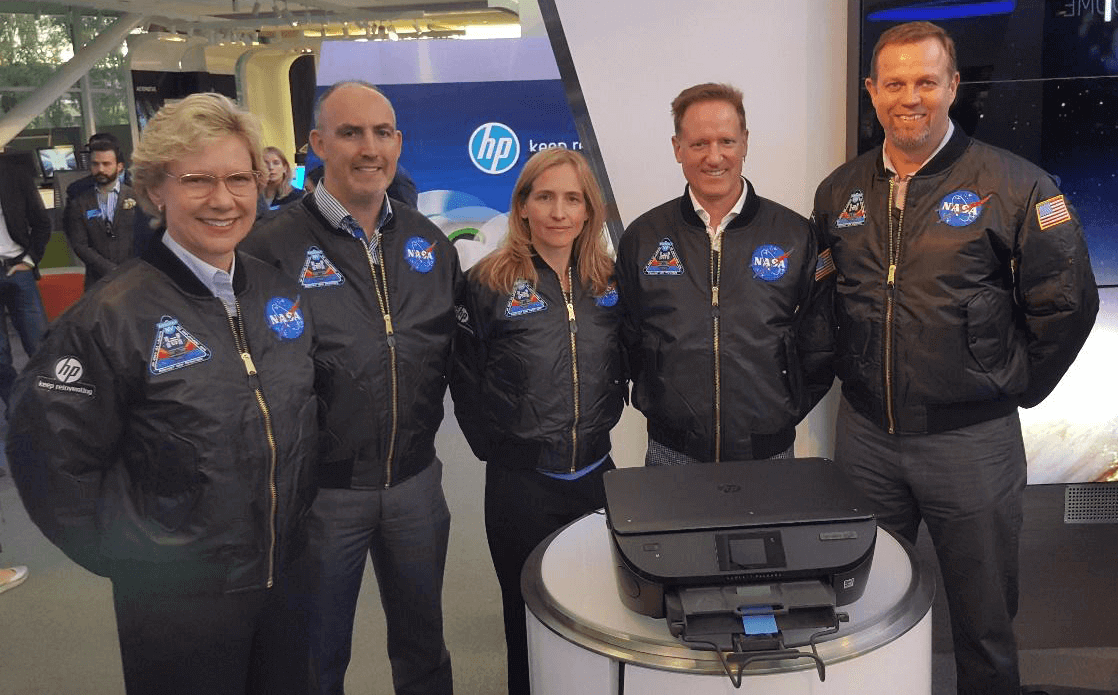

Simplexity CEO, Dorota Shortell (center) with the HP Specialty Printing Systems (SPS) team at the worldwide announcement of the HP Envy ISS printer at HP Headquarters. The jackets are custom-made by NASA for this mission, including the project patch.

NASA project patch that is sewn onto the jackets to commemorate the HP Envy ISS mission (photo credit HP Inc.)