Case Study: Computer aided CPR Training

Students learn faster and have more fun doing it.

What if a device that fits in the palm of your hand could improve CPR technique by providing students with real-time feedback to optimize chest compression and ventilation?

Since its widespread adoption in the 1960s, CPR training has depended on classroom instruction along with one-on-one interaction with an instructor. The training process is time consuming and limited by the availability of trained instructors. Remote regions are often underserved because of instructor shortages. Finally, any complex technique must be practiced to maintain skill level and CPR is no exception. Students may leave the classroom with sufficient skills only to find that their skill level erodes without practice.

Health and Safety Institute (HSI) knew that technology could improve the training process and they came to Simplexity for help.

How We Helped

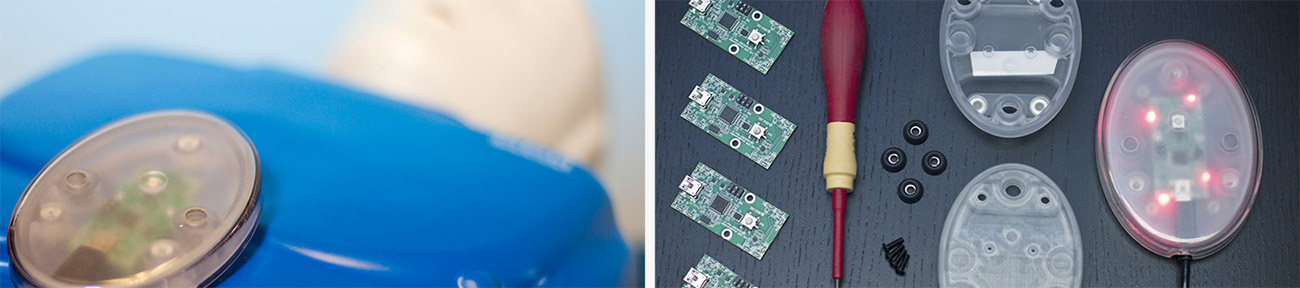

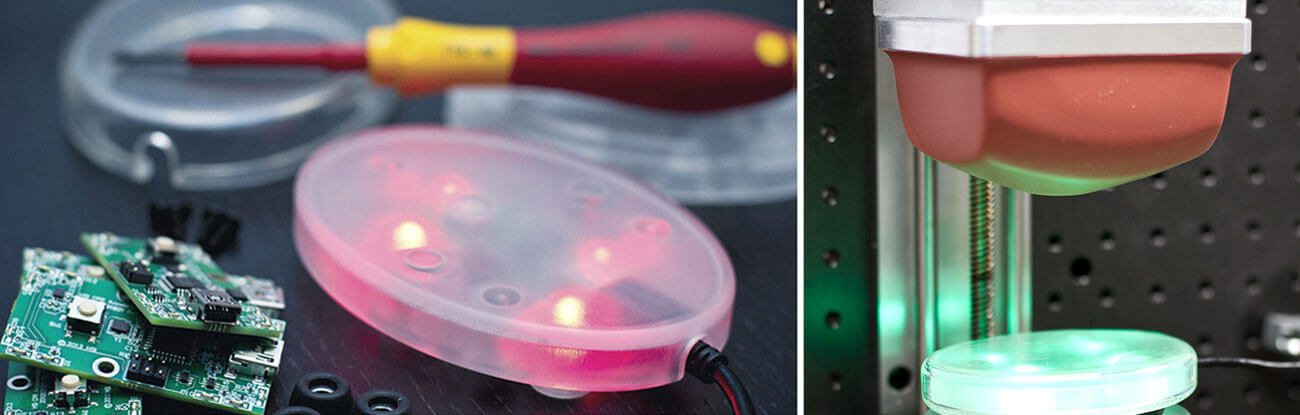

Working in close collaboration with HSI, Simplexity developed a microprocessor based LOOP CPR Controller that is used with a standard CPR manikin during training. When the student performs chest compressions by pushing down on the LOOP, the microprocessor uses internal instrumentation to quantify the student’s compression and ventilation techniques. The LOOP is color illuminated to provide instantaneous feedback and the software logs data for objective scoring of student performance.

The instrumented manikin is an alternative to the LOOP CPR Controller, but because these manikins are so expensive, they are not widely used. The LOOP CPR Controller allows trainers to instrument existing manikins at a fraction of the cost promoting wider adoption of instrumented CPR training.

Development Partnership Yields Impressive Results

During a highly collaborative development effort, HSI provided information on CPR technique and they crafted an engaging software interface. Simplexity carried out the detailed engineering utilizing the “simpler is better” approach. Together the companies solved some challenging issues:

- The device needed to measure both the displacement and rate of a compression, as well as whether complete breaths were properly synchronized to chest compression.

- It had to be robust and durable enough to withstand over a million compressions and continue to function.

- It needed to lie flat on different types of manikins so that an instructor does not need to buy a new or specific type of manikin to use the product.

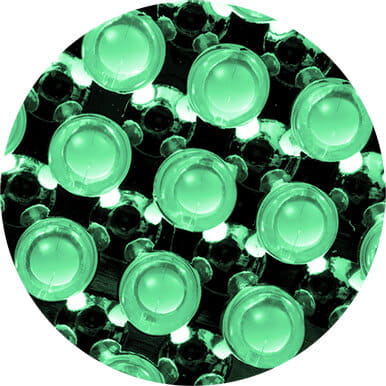

- It needed to provide feedback to the trainee on-the-fly, via LEDs that lit up.

- Finally, the software needed to provide detailed information on the training session and have the ability to store the data.

“We’d never developed a device before and with Simplexity’s guidance it didn’t seem hard. They designed our new LOOP CPR Controller to meet our requirements and work in the simplest possible way. With Simplexity, they don’t say simplification, it’s organic. It’s how they think. The result is exactly the new tool we need to train more students all over the world and save more lives with better CPR.”

-Frank Powers,

Chief Technology Officer, Health and Safety Institute

Just Plug It In And It Works

Simplexity and HSI started the design process by bringing together a broad team for a brainstorming session to think through the many different ways CPR technique could be quantified. After generating a large list of potential technology solutions from these sessions, each idea was assessed against Simplexity’s “simpler is better” approach to design: does this solution allow for the simplest possible design? Does it provide the simplest possible experience for the user? The best of these solutions were then compared to see which would yield the lowest cost designs, taking into account the costs of both the product and the cost of development.

The result was the concept of a CPR device that could be placed on the manikin and then pressed to perform CPR compressions. When CPR breaths are performed, the LOOP rides on top of the chest. The device provides the user a very simple interface: no manikin modifications and no straps needed; just plug it in, place it on the manikin and start improving CPR technique.

Simplexity’s expertise in mechatronics allowed for optimal partitioning of functionality across mechanical, electrical and firmware disciplines. A product like the LOOP is made up of mechanical and electrical components, augmented with smarts: sensors and firmware that runs on a microprocessor on the LOOP, which in turn communicates with software than runs on a PC. To design the best possible system, the functionality of the device was distributed so that each component played to its strength.

Mechanical Development

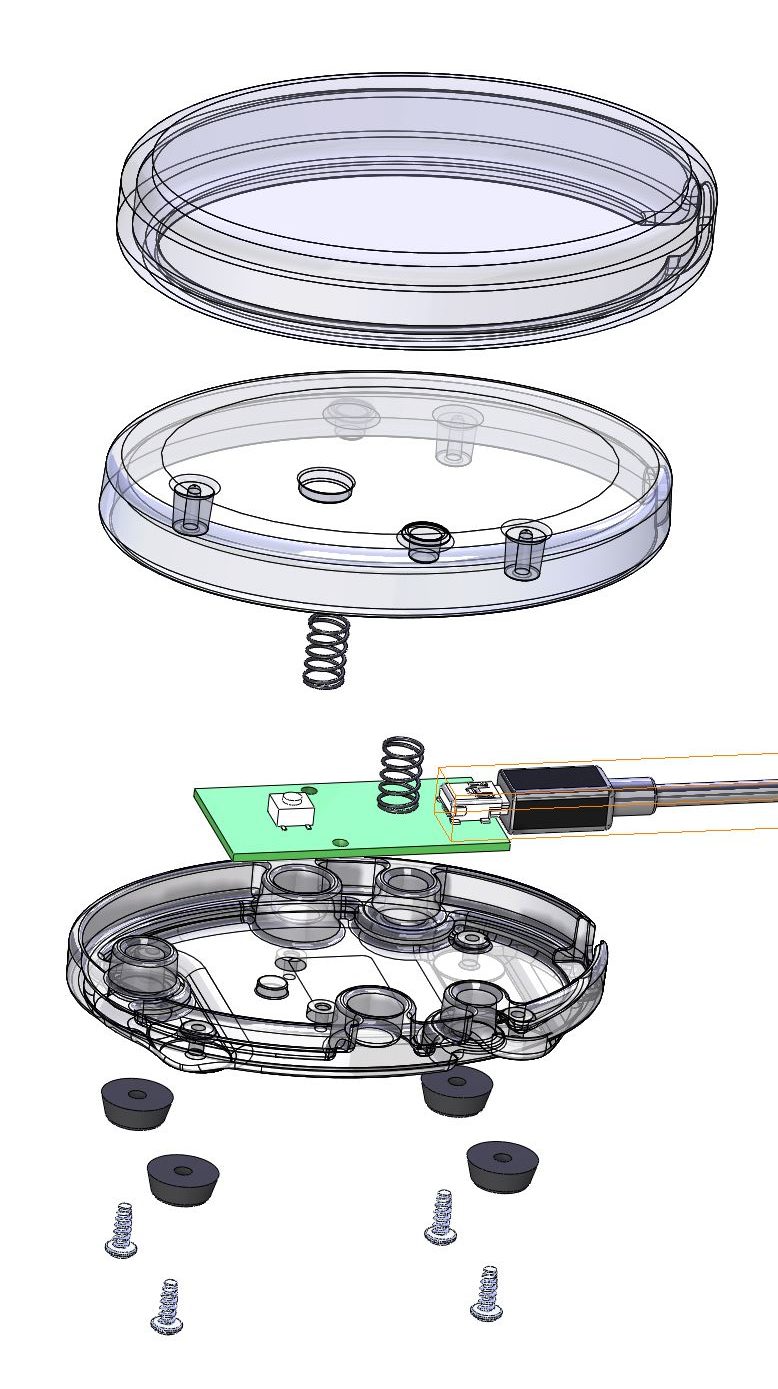

With any mechanical design, reducing the number of moving parts reduces the number of failure points. Making the simplest mechanical design means keeping part count low, and designing the parts correctly for the manufacturing process. The LOOP has only three custom parts, the rest are off-the-shelf components.

In addition, by molding the LOOP housing out of translucent plastic the colored LEDs used for CPR performance feedback could simply shine through the housing without needing special mounting.

Simplexity designed all of the custom parts in SolidWorks® 3D CAD, and selected all of the off-the-self components and fasteners.

Electrical Development

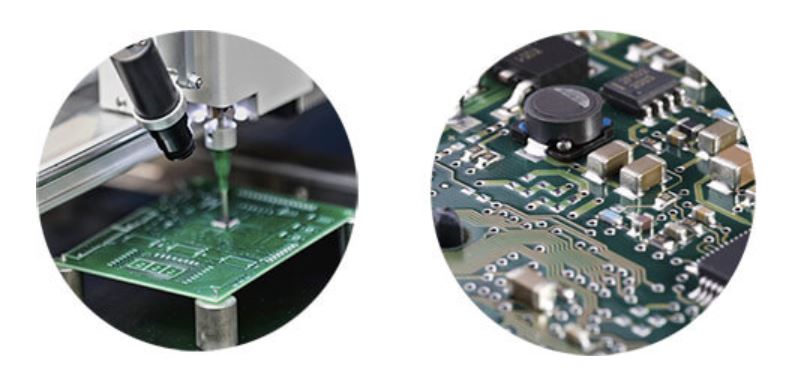

The electrical design focused on keeping things simple too. The system is powered by the USB connection; no batteries required. The system “smarts” are provided by a simple micro-switch, a 3-axis accelerometer/gyroscope combo, and an inexpensive microprocessor that manages reading sensor data, turning LEDs on and off, and sending data to the host PC. This allowed for a small, low cost circuit board

Besides the electrical engineering design, Simplexity managed the selection of suppliers and the process of getting from engineering prototype to final manufacturing release.

Firmware and Software

When it comes to developing efficient product code, the key is to do the right things in the right places. Embedded firmware takes more time to develop than PC software, so only critical functions are performed on the LOOP’s microprocessor. The firmware reads the sensors, does some basic data filtering, then packages the data up and sends it to the host PC over the USB cable. The firmware lights up the LEDs based on simple commands from the PC.

The software is split into layers to simplify and enable parallel development. The Simplexity team wrote the PC software to read data from the USB connection and convert the sensor to CPR data. This data is then passed to HSI’s software to collect it into the CPR training database and display it to the user. By properly partitioning the software architecture, Simplexity and HSI were able to develop in parallel.

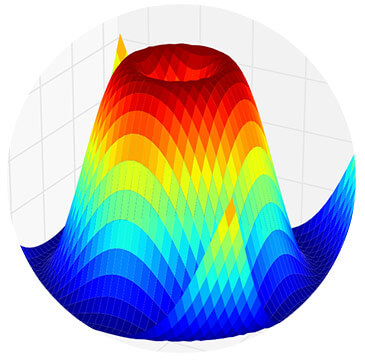

Custom Algorithm Development

Turning simple sensor readings into CPR data requires a set of sophisticated signal processing algorithms. Utilizing state-of-the art tools such as Matlab®, Simplexity developed custom software to convert low cost cell phone sensor data into CPR training data. This software utilizes advanced algorithms including the Extended Kalman filter.

Quick Prototyping To Validate Design Concepts

Prototypes of the LOOP were built throughout the various stages of the development cycle. For the housing parts, machining was chosen over 3D Printing or other rapid prototype methods since the material had to be durable to withstand all the compressions during early life testing. The elastomeric cover was created using rapid prototype methods, by printing a positive that was used to make an inexpensive silicone mold and then casting the covers out of an elastomeric material.

Testing For Toughness

To prove the design is robust enough for use in day-to-day training, Simplexity designed and built a compression life tester, affectionately known as the “Puckinator” since LOOPs were at first called "pucks". This device was built to perform compressions day in and day out, around the clock. While doing the compressions, Puckinator software checked every compression to make sure the LOOP measured the correct depth. The prototype LOOP was tested to one million compressions to verify that the design was robust enough to stand up to the toughest CPR trainees.

Customizing The Supply Chain For HSI

After the prototypes were tested and optimized, it was time to scale-up for production. Simplexity helped HSI source suppliers for injection molding, printed circuit board manufacturing, and final product assembly. Our philosophy is to share all vendors and pricing with our clients, and to help them make the best decisions that are uniquely suited to their business. Simplexity handled the Bill of Materials, and worked with the assembly house to handle the raw material supply chain through customer shipment of the final product.

For a full-service manufacturing solution, Simplexity also created the end-of-line test software to guarantee that every LOOP works correctly before it ships. The LOOP serial number is scanned, a set of tests are performed, and all data is immediately stored in the HSI database online for instant tracking.

Making A Difference

The LOOP is low cost, easy-to-use, and available worldwide. A wider adoption of quantitative CPR training means better trained first responders and, of course, better emergency response outcomes.

Learn more about The LOOP at their website.