CASE STUDY: BIO1 SYSTEMS

Mobile (offline and cloud-based) solutions to enable the seamless capture and transfer of critical medical information using AI-driven clinical data capture and CDS tools for military and civilian applications

THE CHALLENGE

Bio1 Systems, a Bay Area startup, received Phase I and II Small Business Innovation Research (SBIR) contracts from the U.S. Defense Health Agency. The project, “Improved Human Machine Interface Usability for Clinical Healthcare Providers to Enter Data into Electronic Health Records,” focused on developing an efficient, hands-free system for capturing wounded soldier health data in a critical care environment. Data capture would occur through a head-mounted display (HMD) using advanced speech recognition software and an autofocus camera for digital image capture and automatic object detection. Data storage would take place on a disposable Electronic Tactical Combat Casualty Care (E-TC3) tag, which accompanied the wounded soldier throughout initial stabilization and presentation to a treatment center.

Bio1 Systems engaged Simplexity to design, build, and deliver a prototype for the disposable E-TC3 tag. This tag comprised a WiFi Direct communications module, onboard non-volatile memory, a battery, LEDs, and display to illustrate a patient’s health status and severity of injury.

THE DEVELOPMENT

Phase 1: Requirements and Planning

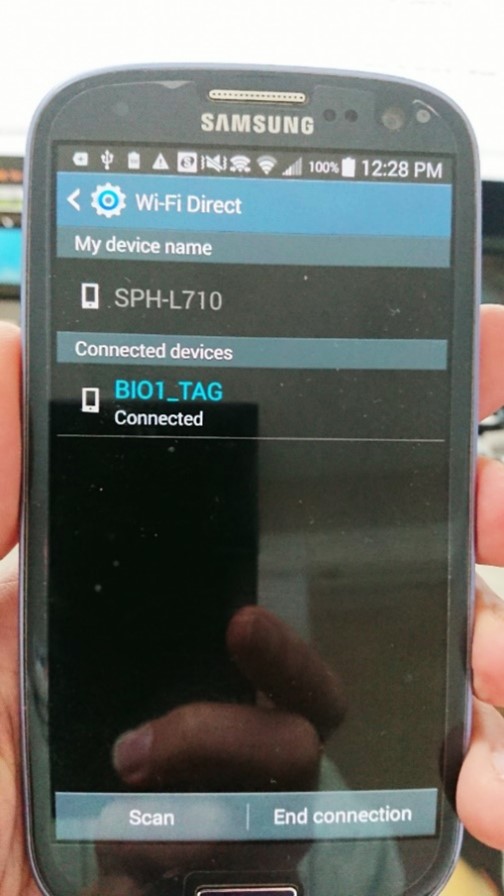

At the beginning of the project, Simplexity and Bio1 Systems discussed the requirements for the prototypes. One important requirement was for the E-TC3 tag to support WiFi Direct, to quickly transmit/receive digital photographs and audio files to/from the HMD. WiFi Direct enables two devices to establish a peer-to-peer WiFi connection, without a wireless router.

For these prototypes, it was useful to walk through a typical use case. The E-TC3 tag was to be stored in a “dormant” state until ready for activation. The medic would attach the tag to an injured soldier (the patient) with a lanyard. The medic would then activate the tag by pulling on a tab. Once activated, the tag was to begin advertising on WiFi, seeking to pair with an HMD. When the tag and HMD were paired, the tag was ready to receive data. The tag would remain operational for a minimum of 24 hours.

Using the HMD, medics would be guided through the process of collecting clinical data by the ATMIST – Age, Time, Mechanism of Injury, Injuries Sustained, Vital Signs, and Treatments – acronym, which appeared on the right side of a user’s view in the HMD. ATMIST is frequently used to collect clinical data in military combat scenarios. Information provided by the medic would be captured using the HMD’s automatic speech recognition (ASR) capability and sent to the tag for storage. Following an intervention, the HMD and tag would unpair, either intentionally (by the medic pressing two buttons simultaneously) or automatically (by the HMD going out of wireless range of the tag). Once unpaired, the tag would be available to pair with another medic’s HMD; for example, on a helicopter headed for a field hospital. The second medic would be able to quickly download all information pertaining to the patient that had been previously entered.

Another requirement was for the tag to have a display, which would allow a medic to quickly review ATMIST data without wearing an HMD. To prevent the light from the tags from giving away the position of an injured soldier at night, the display should only light up when a button is pressed, and only for a few seconds. Additionally, the prototype E-TC3 tag needed to have LEDs (for example, in the shape of a ring, such as the Amazon Echo) that displayed a color to highlight the priority level for patient triage.

Data was to be stored on the HMD and transferred to the tag using an Extensible Markup Language (XML) schema. XML was selected instead of JavaScript Object Notation (JSON) because it is used by the Medical Communications for Combat Casualty Care (MC4) group in their information management systems. The XML data structure and images would be transmitted to the E-TC3 tag over WiFi Direct upon every information update.

Phase 2A – Architecture

With a firm understanding of the requirements, Simplexity began work on the architecture of the prototypes. To allow maximum flexibility, we decided to separate the WiFi module from the microcontroller unit, or MCU (some WiFi modules boast built-in MCUs but this makes it harder to swap components in the future). MCUs from STMicroelectronics were found to be suitable, and Simplexity has extensive experience with the STM32 series ARM-based MCUs.

The MCU communicated with the WiFi module, the on-board memory (a 32GB microSD card), LEDs for the light ring, buttons, and the display. The requirement for the display to be normally-off made LCD displays with back-lighting attractive, as they would draw too much power if on continuously. We chose an LCD display with 320 x 240-pixel resolution, measuring around 3.5” on the diagonal.

For the battery, we proposed a lithium sulfur dioxide (LiSO2) or similar primary cell battery. This battery chemistry is known for its wide operating temperature range, flat voltage-discharge curve, and high energy density. Furthermore, the military has been a user of this chemistry in the past. Lithium sulfur dioxide does require some care to function properly. After long storage or being subjected to low temperatures, the terminal voltage may dip suddenly at the first application of a load and then recover. Ultimately, Bio1 Systems chose to forego LiSO2 in favor of two standard AAA batteries, as this would be simpler to use in these prototypes.

Phase 2A – Breadboarding

In this phase, Simplexity created a breadboard solution with development boards for the STMicroelectronics STM32 (NUCLEO) and WiFi module, as well as samples of the display. Firmware efforts focused on getting all the required libraries loaded and drivers written. A regular Android smartphone was used as a proxy for the HMD to demonstrate WiFi Direct functionality. On the mechanical side, the efforts focused on determining the minimum possible size of the prototype. This included selecting acrylic material for the light ring and breadboarding with surface-mounted LEDs in various configurations.

Phase 2B – Detailed Design (Proof of Concept)

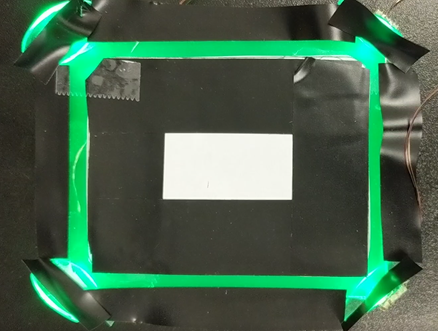

Having proven the concept, Simplexity engineers set about adding the necessary functionality for the prototypes. For our electrical engineer, this meant creating a schematic and layout for the custom circuit board. Our electrical engineer worked closely with our mechanical engineer to package all the components in the tightest possible space. We chose to machine, rather than 3D-print the case parts, due to their increased durability in the field.

The bulk of the work fell to the firmware engineers, who had to build in all the missing functionality, which included working out the details of the state machine. Simplexity also worked with Bio1 Systems software engineers to specify the application programming interface (API) between the Android-based HMD (or smartphone) and the E-TC3 tag. For the communication protocol, we agreed on opening a Transmission Control Protocol (TCP) socket to set up a client/server network for bidirectional data transmission. On the tag side, our firmware engineers had to create a secondary state machine to handle the XML schema parsing, while Bio1 Systems engineers did the same on the Android side. Once the XML parsers were aligned on both ends, the full pipeline was tested to make sure there was no loss of data.

Additionally, the necessary pages for the display had to be programmed. These included a QR code page on start-up for HMD pairing and several pages for showing vital signs. The most challenging page was the “stickman,” a graphical representation of the location, type, and severity of wound sustained. Processing a large JPEG or bitmap file would create memory constraint issues, as well as require long loading time. Instantiating the stickman as a bitmap array allowed the design to be treated as a font, preserving memory and reducing loading time.

Having proven that we could write text data to the SD card, our firmware engineers extended the code to support JPEG images and audio files. Code was also added to read and return contents of the SD card in response to an HMD request for stored data. In all, the API comprised four basic data transfer operations: audio, image, and ATMIST text transfer from HMD to tag, and transfer of cumulative data from tag to HMD. Lastly, the team implemented the necessary button and LED light behaviors. Once all code was in place, we subjected the tags to rigorous testing of all defined use cases to ensure they were ready to use in the field.

THE RESULTS

Simplexity was able to work with Bio1 Systems to effectively gather device requirements and develop an initial design plan. This plan included prototype architecture, breadboarding, and the eventual detailed proof of concept prototype.

In the simulated military combat scenario, a soldier had suffered a traumatic below-the-knee amputation, as well shrapnel wounds and burns caused by an improvised explosive device. The soldier was removed from the burning vehicle as the medic approached to treat the patient. With the aid of the HMD and E-TC3 tag, the medic treated the soldier with a tourniquet, pain medication, and intravenous fluids. Bio1 Systems collected quantitative data on factors such as ASR performance (word error rate). Bio1 Systems also received qualitative feedback from the medics in the form of 30-minute semi-structured interviews. The technical performance of the tag was critical in making the futuristic scenario as realistic as possible.

Another key contribution by the Simplexity team, the API, proved extremely useful when Bio1 Systems was asked to develop a simulated electronic health record (EHR) system, such as those found in field hospitals. Bio1 Systems software engineers developed a tablet-based Android application that leveraged the existing API to exchange data with the tag. The downloaded files could be viewed on the tablet, saved to the EHR, and even be uploaded to the cloud. Because Simplexity had thought up-front about how to make the system as extensible as possible, Bio1 Systems was able to demonstrate the additional simulated EHR functionality without any incurring additional hardware development expenses.

The Bio1 Systems device offers an efficient data collection and feedback mechanism in military critical care environments with the potential to enable medics to improve patient treatment options.