What is a Motion Control System?

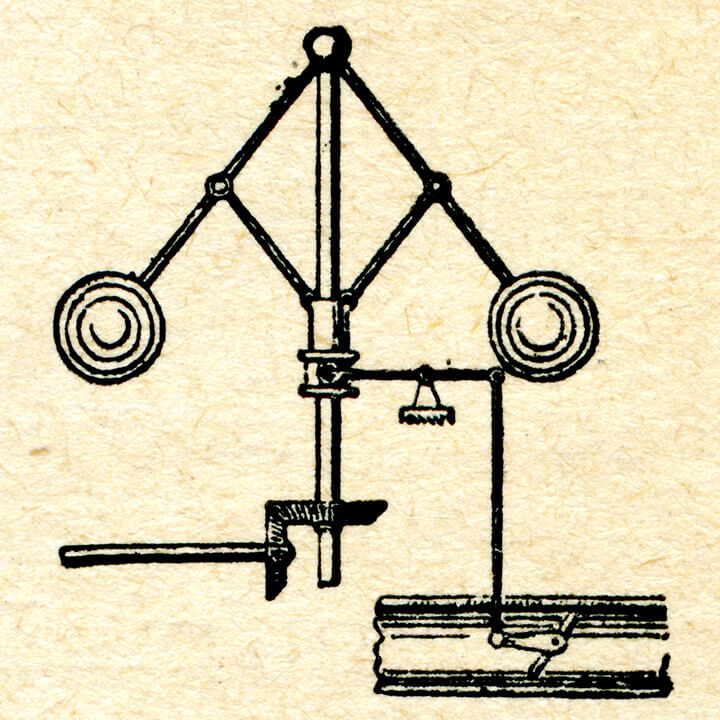

At the most fundamental level, a motion control system is any system that controls energy flow to generate mechanical motion with some desired properties. One of the earliest examples was the flyball governor, shown here, that was developed in the 1780’s. This control system for the Watt steam engine used the centrifugal forces of the balls to set a throttle angle and main constant engine speed.

While flyball governor is a purely mechanical control system, modern day motion control systems typically convert electrical power to mechanical motion with an electric motor, and do so under the supervision of a computer.

The following discussion addresses motion control systems from two aspects: the flow of power (needed to make things move) and the flow of information (needed for control) through the system.

Flyball Governor

POWER FLOW

In this discussion, I’ll focus on the motion control systems used consumer products and laboratory automation of today. These systems consist of the following major components:

- DC Power Supply – Converts from 50 Hz or 60 Hz AC electrical power of the grid to a fixed DC voltage. DC power is used to drive the different classes of DC motors: brushed, brushless and stepper. Voltages above 42.4 V require additional safety precautions, providing an incentive to stay below this level.

- Motor Drive Electronics – Modulate the fixed value DC voltage from the power supply in the manner required to drive the motor. There are actually two types of modulation that are required:

- The first sets the nominal input voltage for the motor so that the desired speed or torque may be achieved. This is the “amplification stage”. The two basic classes of amplifiers are linear and switched. Linear amplifiers are most useful in situation where low electrical noise is critical, with the tradeoff of inefficiency in the form of heat generation in the amplifier itself. Pulse width modulation (PWM) switching amplifiers are more efficient, but can inject high frequency noise into your system.

- The second switches the voltage appropriately to make the motor spin. This is the “commutation” stage. Brushless DC and stepper motors require the voltages to be switched by the controller/driver as a function of motor position in order to keep the motor moving. Brushed DC motors are constructed so that this function can be performed mechanically, and as such, are the simplest to drive.

- Motor – Converts the input electrical power into an output mechanical power: Voltage and current IN, torque or force and speed OUT. While rotational motors are by far the most common, there are linear versions of motors that provide advantages in some situations. A common example is the voice coil motor (VCM).The motors used in consumer products and lab automation are all based on the same basic idea: an electro-magnet formed by a coil of copper is driven with an input voltage and interacts with a permanent magnet to generate force or torque.The common types of rotary motors are:

- Brushed DC – As described above, brushed DC motors use mechanical brushes to make/break contact with the different coils, known as windings. Applying a constant input voltage will cause the motor to spin at a constant speed dependent upon the shaft load. Typically, the permanent magnets are on the portion of the motor that does not spin (the stator), and the windings are on the rotating portion of the motor (the rotor).

- Brushless DC (BLDC) – Brushless DC motors may look similar to brushed DC motors, but are quite different in usage. BLDCs contain no mechanism to switch which field is active, thus cannot spin on their own. The controller & drive electronics work in conjunction to vary the winding voltages to generate a rotating magnetic field within the motor. This generates a force upon the magnet on the rotor, and causes the motor to spin. BLDCs typically have three electrical phases which are driven with some sort of a sine wave voltage.

- Stepper – Stepper motors are a two-phase or four-phase version of the BLDC technology. However, their construction is significantly different. Stepper motors are built so that application of voltage to a set of windings will cause the motor to move, or “step”, to a fixed position. This makes it very simple to construct a positioning system from a stepper motor. By stepping in rapid succession, stepper motors can achieve a roughly constant velocity.

- Drive Mechanics – Typical motion control systems use a rotary motor to drive a load that may need linear or rotary motion at a different torque and speed. In either case, there is a mechanism that converts from the motor shaft output to the motion required for the load.

- Load – The load is the end-point of the motion control system. It is the portion of the system about which the outside world is concerned. The load requirements of the load’s motion will drive the requirements of the upstream system. The parameters of concern are the load mass and friction, and the motion profile that must be followed. The motion profile defines the acceleration, velocity and position requirements for the system. Taken together, this defines the input power: the force or torque the system must provide to the load, and the speed at which that force or torque must be delivered.

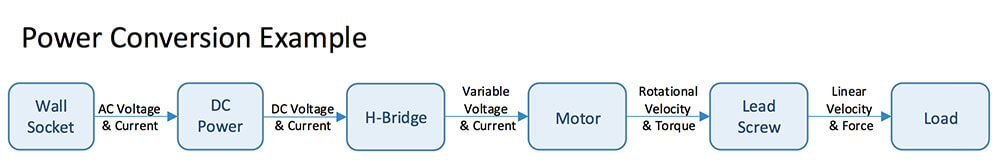

The diagram below shows the power flow for a typical motion control system consisting of a motor driving a lead screw based linear stage.

POWER CONVERSION

While the load defines the mechanical power output required, each of the other components described in the previous section performs a power conversion function. Power conversion is a critical part of a motion control system design that is often overlooked. There are two key aspects to a power conversion process:

- Efficiency – No power conversion process is 100% efficient. During conversion, power is lost through a variety of mechanisms such as friction, Ohmic/resistive/Joule heating, switching losses, eddy currents, and noise. Consideration should be taken to minimize these losses to acceptable levels. In addition, most of the inefficiencies take the form of heat generation. Each component will have its own ability to dissipate heat, as well as a degradation in performance with increased temperature. To minimize system cost, the system should be designed so that heat is dealt with in the most cost efficient manner.

- Impedance Matching – Power is the product of two variables: force (or torque for a rotary system) and speed for mechanisms, and voltage and current for electrical systems. Power conversion can occur within a domain, or across domains. Examples:

- A 24V DC power supply takes an input of 120V (in the US) at a low current, and outputs 24V at a higher current.

- A car transmission and drivetrain that converts the high speed, lower torque engine output to a lower speed, higher torque at the cars wheels.

- A DC motor takes an input of voltage and current, and outputs shaft torque and speed.

Efficiency and impedance matching can be used to offset one another. In the example of a DC motor, torque is proportional to current, and speed is proportional to voltage. Thus if you have a system where the motor is overheating due to excessive resistive losses, one option is to reduce the current (which drives the resistive loss) by reducing the torque output required. This might require changing a mechanical gear ratio so that the motor can run at a higher speed, while maintaining the same shaft speed at the load. This solution may be cheaper than moving to a larger motor.

The previous example also demonstrates how the components work together. The key point here is that all of the components affect each other, and are thus equally important. All too often, I’ve seen engineers focused solely on resolving issues via a motor change when the best solution was to modify one of the other components.

DATA FLOW

Now that we’ve covered how power moves around inside of a modern motion control system, we’ll discuss how information flows to perform the “control” function. The information flow portion is simpler than the power flow, consisting of following major components.

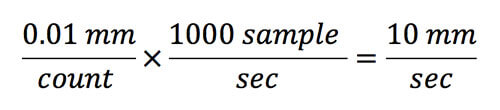

- Sensors – While there are plenty of open-loop motion control systems in the world, closed-loop control is typically used to increase overall system performance. In order to implement a feedback control system, a sensor is required to measure something about the system that is related to the aspect you’re trying to control. Ideally, the sensor is placed directly on the mechanical element which you are trying to control. For example, if you care about a stage’s linear position, you would use a linear encoder to measure that position. In many cases this is not feasible, so you might measure the rotary position of the lead screw which drives the stage instead. Doing so trades simplification of the mechanical issue of encoder placement for inclusion of lead screw errors into the positioning error budget. Be cognizant of the trade-offs being made with sensor placement.Another important sensor consideration is resolution. Sensor resolution will drive both achievable stopping accuracy and velocity ripple. A good rule of thumb for stopping accuracy is to have a sensor resolution 10 to 20 times greater than the stopping accuracy specification.Achievable velocity ripple is driven by both the sensor resolution and the control algorithm sampling rate. The minimum resolvable velocity error is one sensor count per time sample. For example, with a sensor resolution of 100 counts per millimeter, and a control algorithm sample rate of 1000 Hz, the minimum detectable velocity error is:

Thus attainable the velocity ripple is 10 mm/sec at best. Higher sample rates provide more controllability for the system, but require higher resolution sensors also.

- Desired Trajectory – While the sensor tells us what the system is doing, it is the desired motion trajectory generator that describes what we want the system to do. A constant velocity is a very simple trajectory to create. A point-to-point position control with jerk limits is substantially more complicated to create. It is important to note that the acceleration and velocity command of the desired trajectory will directly affect the inertial and friction loads to which the system is subjected.

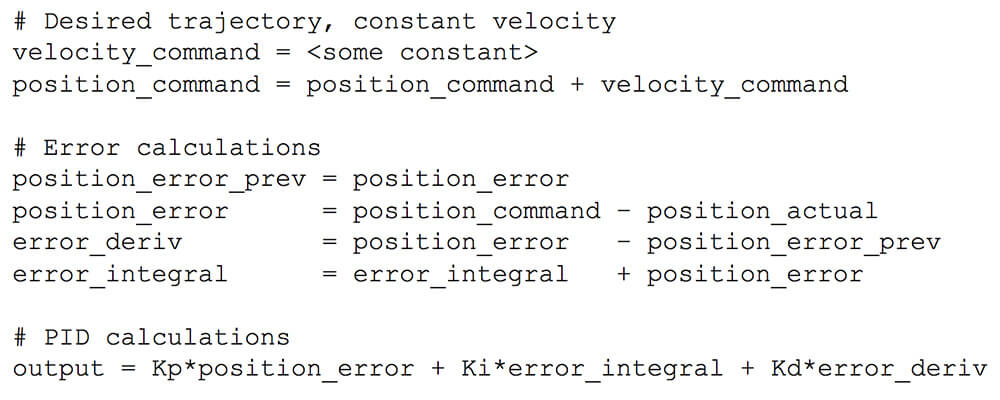

- Feedback Control Algorithm – Between the desired trajectory and the sensor, we know both what we want the system to do, and what it is actually doing. The feedback control algorithm combines these pieces of information to generate a command to the drive electronics that will induce motion in the system.By far the most common control algorithm in use is the proportional-integral-derivative (PID) algorithm. This algorithm calculates the control input as a function of the control error, its integral and its derivative. Pseudocode for a PID algorithm is shown below. These calculations would be run every control sample period.

The PID algorithm is relatively easy to tune and handles many problems quite well. In addition, it is typically the only algorithm to receive significant attention in undergraduate controls courses. These reasons lead to the PID algorithm being the most commonly used control algorithm in practice by a wide margin. However, it is important to note that there is a world of advanced control algorithms that can significantly outperform PID in many situations.

Motion control systems deal with both energy and information flow through a system in a dynamic manner. With proper design and component selection, they can be efficient and elegant systems that enable incredible capabilities in consumer products and lab automation systems.

Wanna learn more about motion control systems?

Check out:

The PID algorithm is relatively easy to tune and handles many problems quite well. In addition, it is typically the only algorithm to receive significant attention in undergraduate controls courses. These reasons lead to the PID algorithm being the most commonly used control algorithm in practice by a wide margin. However, it is important to note that there is a world of advanced control algorithms that can significantly outperform PID in many situations.

The PID algorithm is relatively easy to tune and handles many problems quite well. In addition, it is typically the only algorithm to receive significant attention in undergraduate controls courses. These reasons lead to the PID algorithm being the most commonly used control algorithm in practice by a wide margin. However, it is important to note that there is a world of advanced control algorithms that can significantly outperform PID in many situations.