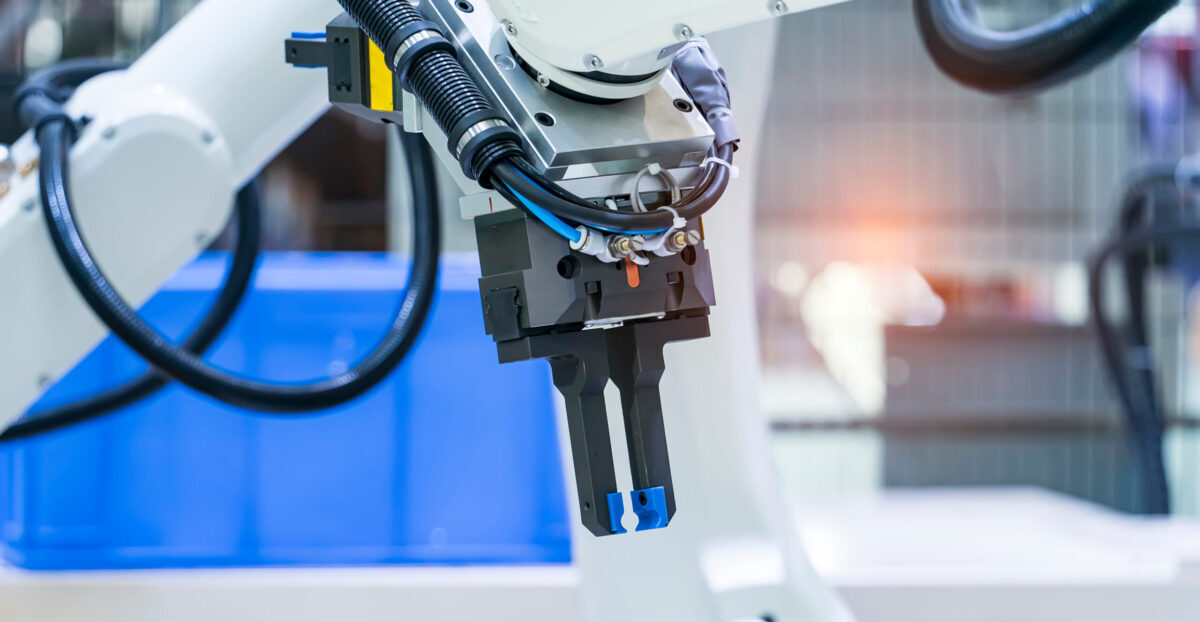

Over 25 years ago, when I first set out on a career in Mechanical Engineering, I was captivated by the promise of robotics. Yet early on, much of my work centered on mechatronics—designing and developing sophisticated systems, from particle detectors at MIT to scanning electron microscopes at FEI (now Thermo Fisher Scientific). In 2008, I shifted focus to industrial automation, leading engineering and sales at DWFritz Automation. There, my teams designed and installed thousands of robotic systems across North America and Asia.

1998 magnetic science experiment at MIT Bates

1998 magnetic science experiment at MIT Bates

Today, both mechatronics and robotics have matured dramatically, from niche disciplines to foundational technologies driving modern automation. Understanding their origins helps us better appreciate just how transformative they’ve become.

A Brief History of Mechatronics

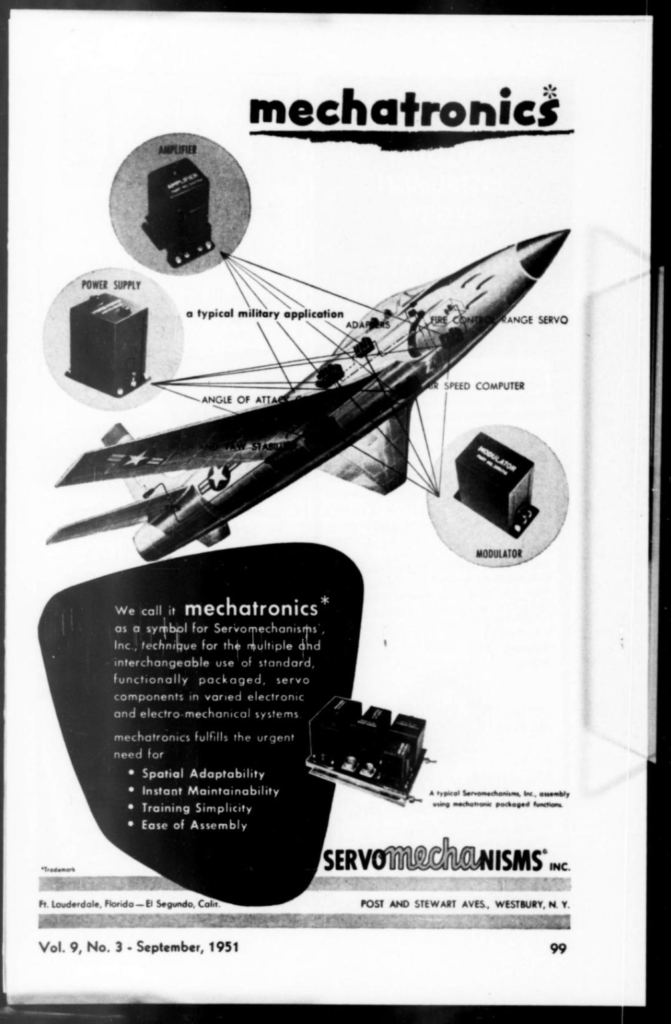

Mechatronics was popularized in the 1960’s, a term coined by engineers at Yaskawa Electric Corporation to describe the fusion of mechanical and electrical systems. Over time, it expanded to include electronics, control systems, and software. By the 1980s and 90s, mechatronics had become essential in building smarter machines, like anti-lock brakes in cars or computer-controlled manufacturing systems.

“Mechatronics advertisement”. Nucleonics. Vol. 9, no. 3. The McGraw-Hill Companies. September 1951. p. 99 – via Internet Archive.

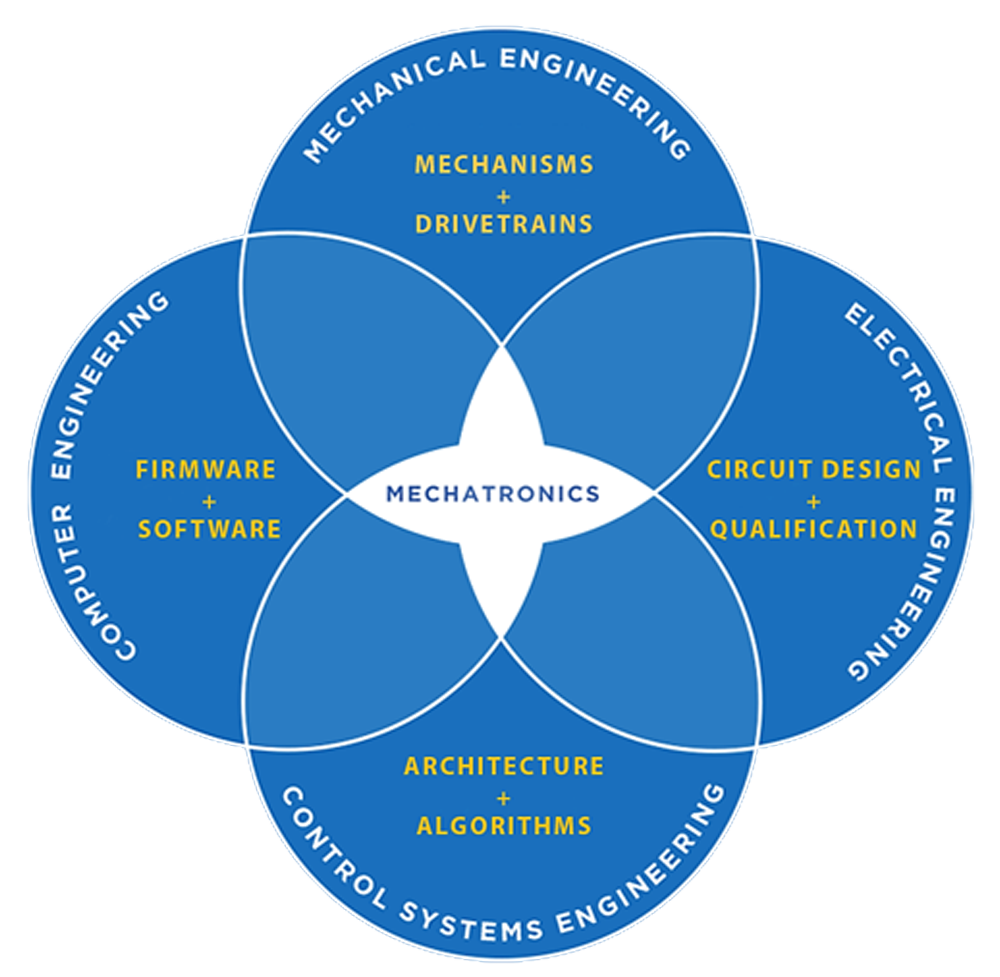

Modern mechatronics is all about creating intelligent, responsive systems. It’s not just about integrating parts; it’s about enabling machines to sense, decide, and act in real-time.

Mechatronics Venn diagram

A Brief History of Robotics

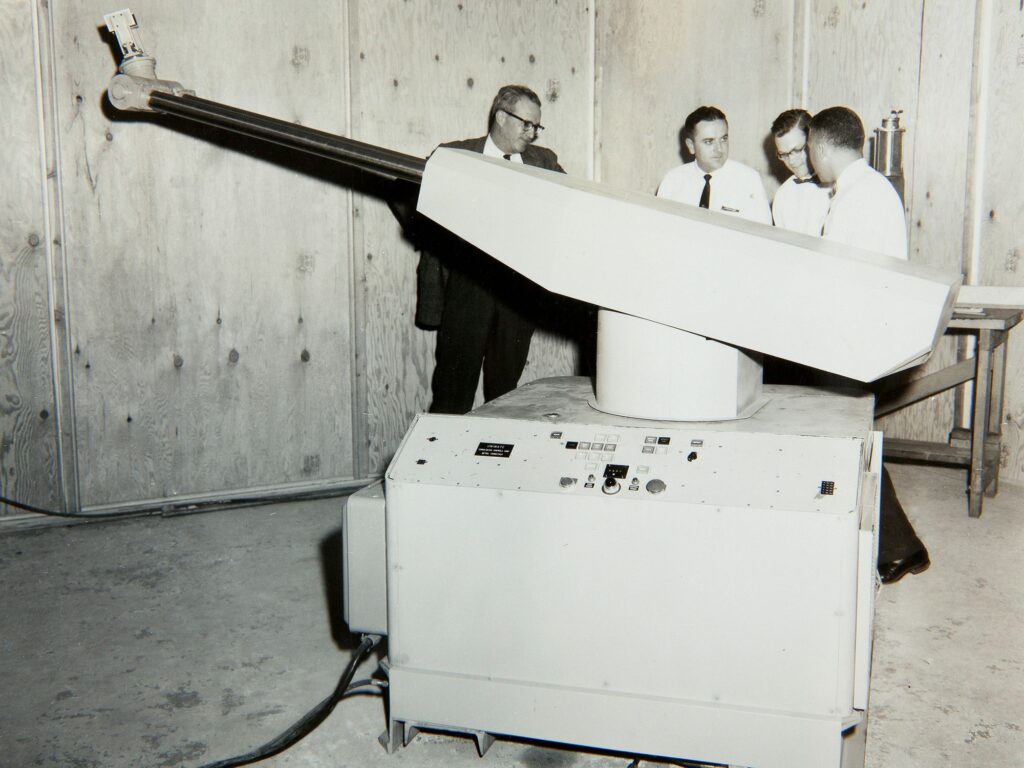

The modern era of Robotics began in the mid-20th century. In 1961, General Motors deployed the first industrial robot, “Unimate,” to automate spot welding on a production line, ushering in a new era of manufacturing.

Since then, robotics has evolved rapidly. What started as fixed, repetitive machines has grown into a diverse ecosystem, from surgical robots to warehouse automation, agricultural drones to space exploration. Today’s robots are increasingly capable of seeing, thinking, and adapting, thanks to advances in AI, computer vision, and sensor technologies.

Unimate – ROBOTS: Your Guide to the World of Robotics

Where We Are Now

Both mechatronics and robotics are evolving rapidly. In addition to the traditional intersecting fields, Mechatronics now adds in the fields of AI (Artificial Intelligence), and is powering everything from autonomous drones to smart surgical tools. Robotics, once defined by rigidity and repetition, is now about flexibility, collaboration, and real-time intelligence.

We’re seeing a surge in collaborative robots, autonomous vehicles, and AI-driven automation that can learn and adapt. Innovations in edge computing, simulation and digital twins (a virtual model that mirrors the physical object or process) are lowering the barrier to design, test and deploy advanced robotic systems in real-world environments.

Looking Ahead

As mechatronics and robotics continue to evolve and converge, they’re reshaping industries, and redefining what’s possible. Machines are no longer just tools; they’re becoming collaborative partners in innovation. I recently joined Simplexity to further advocate for the collaboration of these converging disciplines.

At Simplexity, our team of engineers thrives at this intersection. We’re passionate about pushing boundaries and excited to help bring the next generation of intelligent machines to life.

References

Some historical data on robotic installations in the US/North America:

As of the end of 2023, approximately 381,964 industrial robots were operational in U.S. manufacturing facilities, marking a 10% increase from the previous year. This growth underscores the nation’s commitment to enhancing automation across various industries.

Source: American Machinist

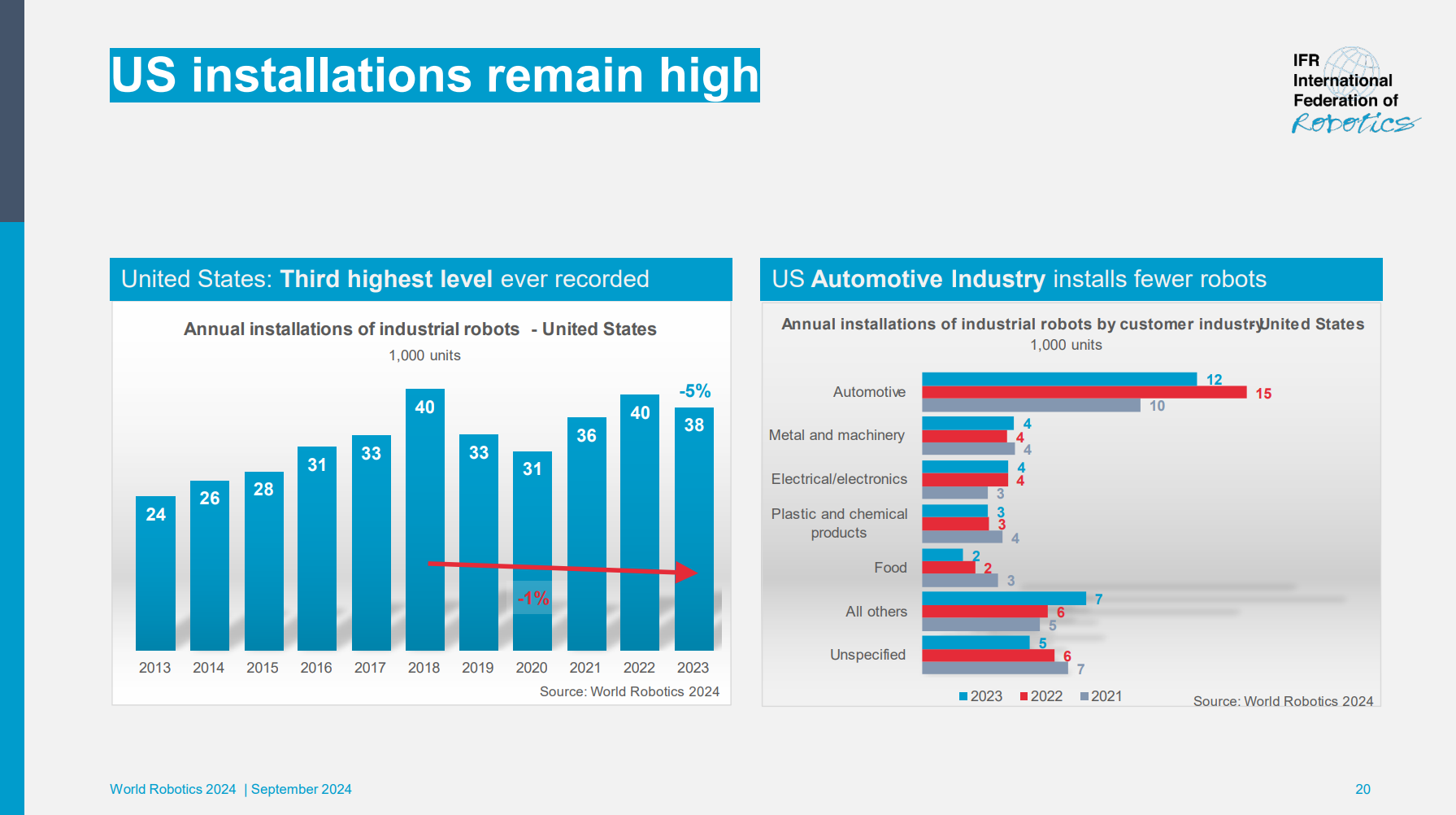

In 2023, the United States installed 37,587 new industrial robots, a 5% decrease compared to 2022. Despite this slight decline, it was still the third-highest annual installation figure in U.S. history . The automotive sector remained the leading adopter, accounting for 33% of all installations, followed by the metal and machinery industry, and the electrical/electronics sector.

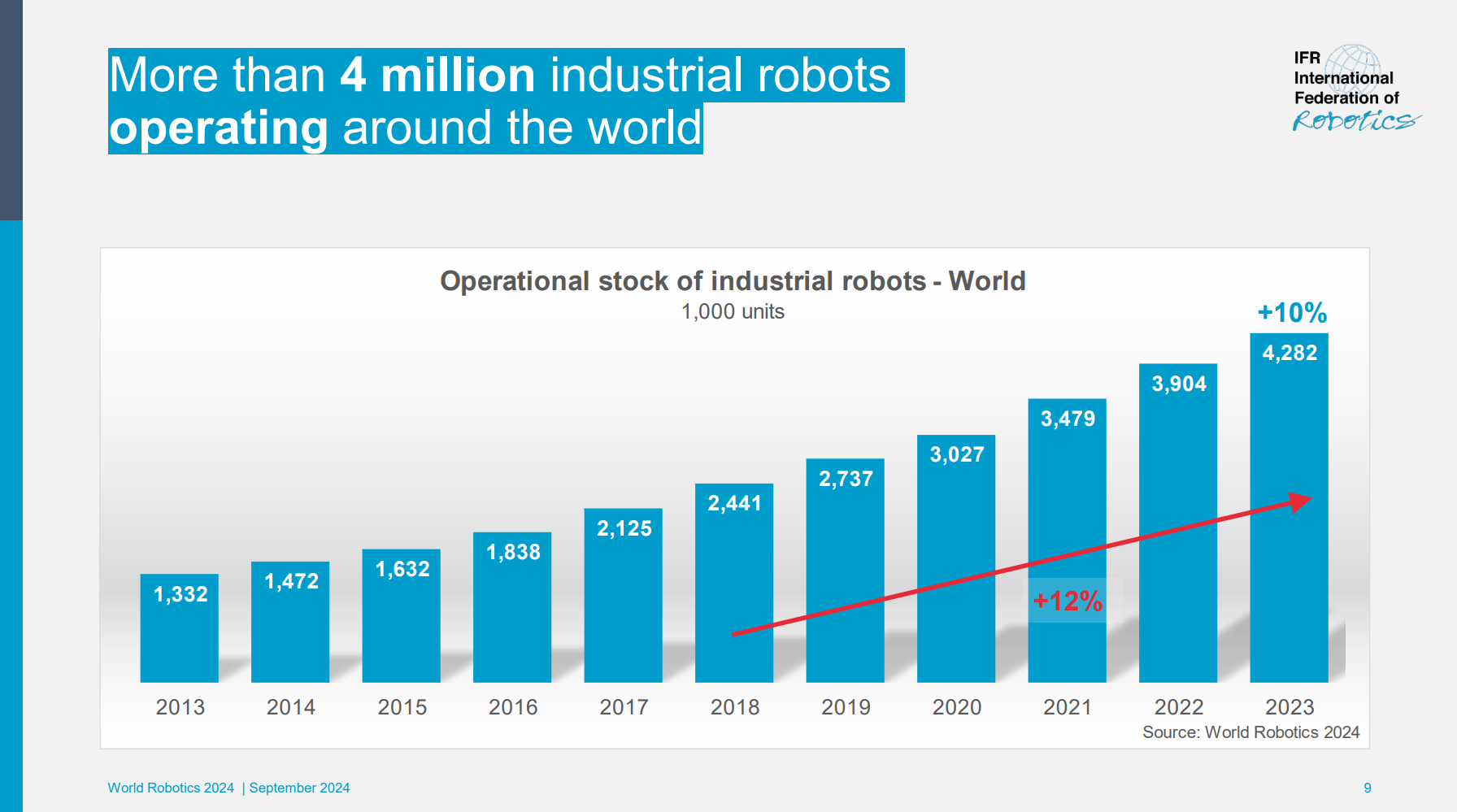

Globally, the total number of industrial robots in operation reached approximately 4.28 million units by the end of 2023, with the United States contributing nearly 9% to this global figure.

Looking ahead, the U.S. robotics industry is poised for continued growth, driven by factors such as the transition to electric vehicles, efforts to strengthen domestic supply chains, and advancements in automation technologies.

Source: World Robotics 2024 Report by International Federation of Robotics

Page 9 – IFR Presentation: International Federation of Robotics World Robotics 2024 press conference with charts

Page 20 – IFR Presentation: International Federation of Robotics World Robotics 2024 press conference with charts