The Shark AI Ultra 2-in-1 robot vacuum is a smart and innovative cleaning appliance designed to make your cleaning experience easy, effective and hassle-free. It comes with advanced features like voice control, mobile app compatibility, and automatic charging, making it a popular choice among consumers. In this teardown blog, we will explore the internal components of the shark robot vacuum and explain how it works.

AI Integration

AI is employed in this robot vacuum model and, by using various sensors, such as cameras, infrared, and sonar, the robot can perceive and interpret the environment. Machine learning algorithms then analyze this data to create maps of the space, detect obstacles and map out optimal cleaning paths. This allows robot vacuums to move intelligently around a room, avoiding obstacles such as furniture and stairs. AI also optimizes the cleaning path, reducing the time required to clean the space, thereby minimizing battery run time. Additionally, this AI-enabled vacuum can be integrated with IoT technologies like smartphones, tablets, and smart home systems, such as Alexa or Google Assistant, to allow for voice commands and scheduling of cleaning tasks.

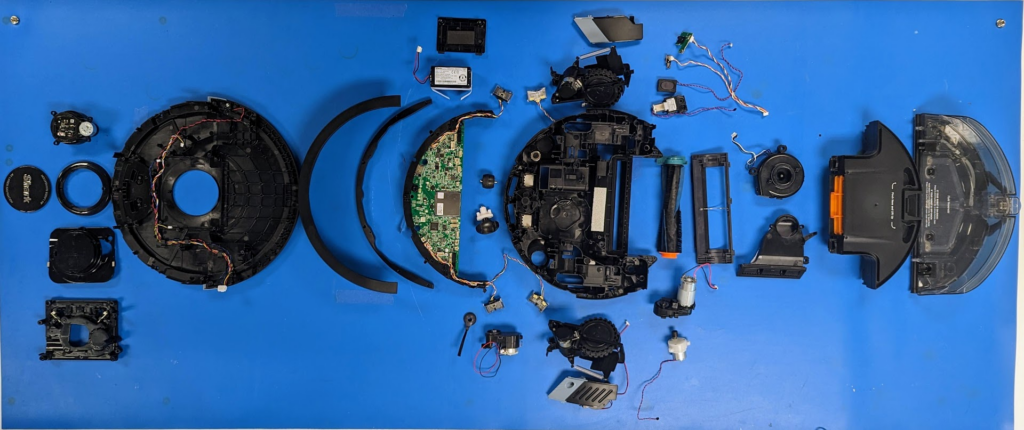

Shark AI Robot Teardown

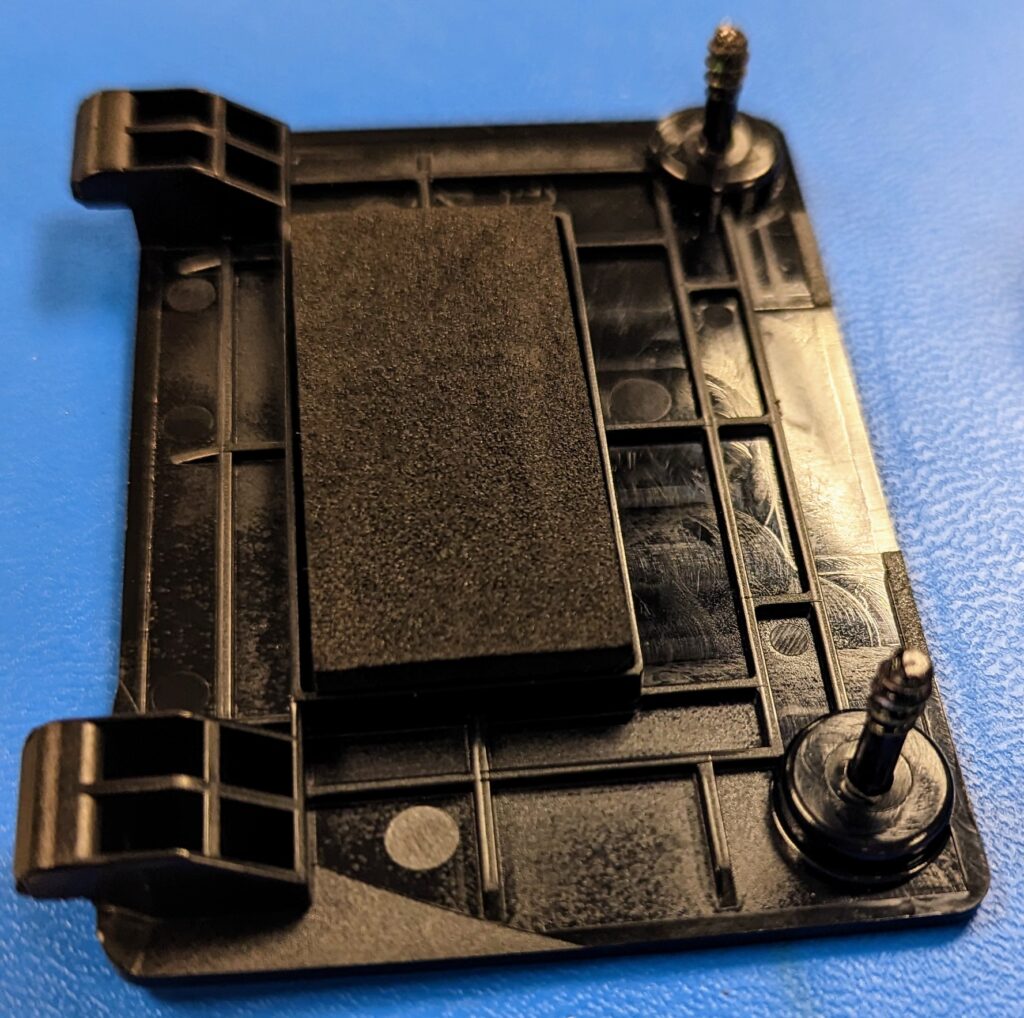

Captive Screws for Common Access Areas

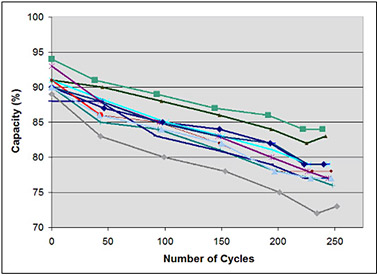

First, we remove the battery from the device before digging into any of the deeper components. Consumer products often have user-replaceable batteries as they will degrade over time. Engineers use captive screws on removable components to ensure that, when the cover is removed, the screws do not get lost. In this case, the threads are used to captivate the screws as the threads are larger in diameter than the hole, a clever and inexpensive way to accomplish this.

| Lithium Ion Battery Degradation | Captive Screws on Battery Cover |

Credit: Battery University |

|

Modular Design

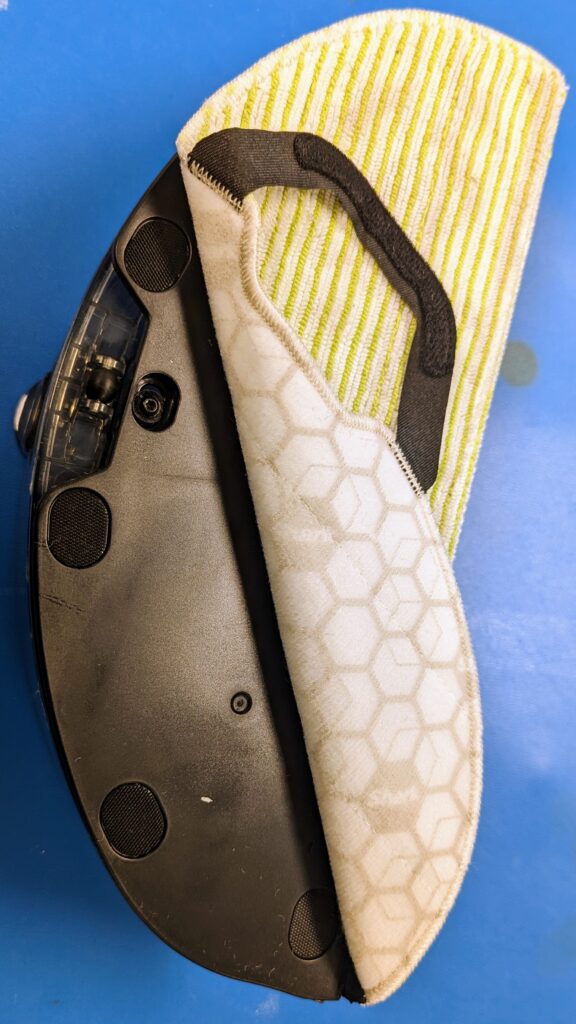

When parts of the device need to be customer serviceable, the replaceable components need to have easy access, with few additional parts to remove to replace the damaged part.

By employing a modular design, the useful life of the product as a whole can be increased significantly.

The replaceable components of this vacuum are:

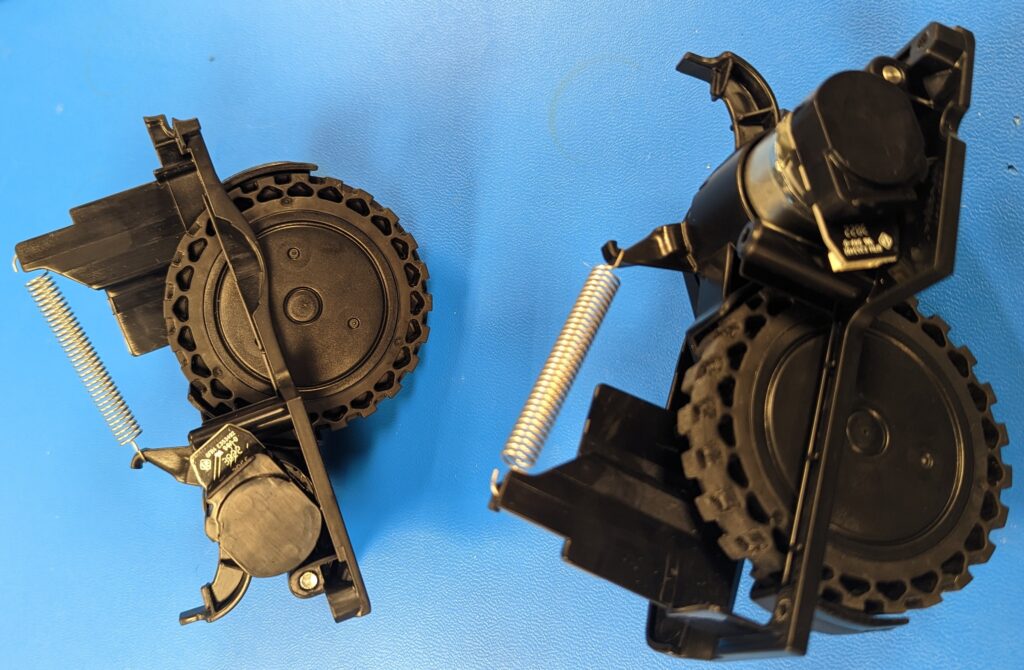

| Battery | Vacuum Roller Brush | Dust Bin & Filter | Mopping Reservoir & Pads | Left/Right Wheel Assemblies |

|

|

|

|

|

Motion Components Inside the Shark Vacuum

There are many moving parts that live inside of a robot vacuum. Each has its own requirements and are all driven in tandem to allow the vacuum to function properly.

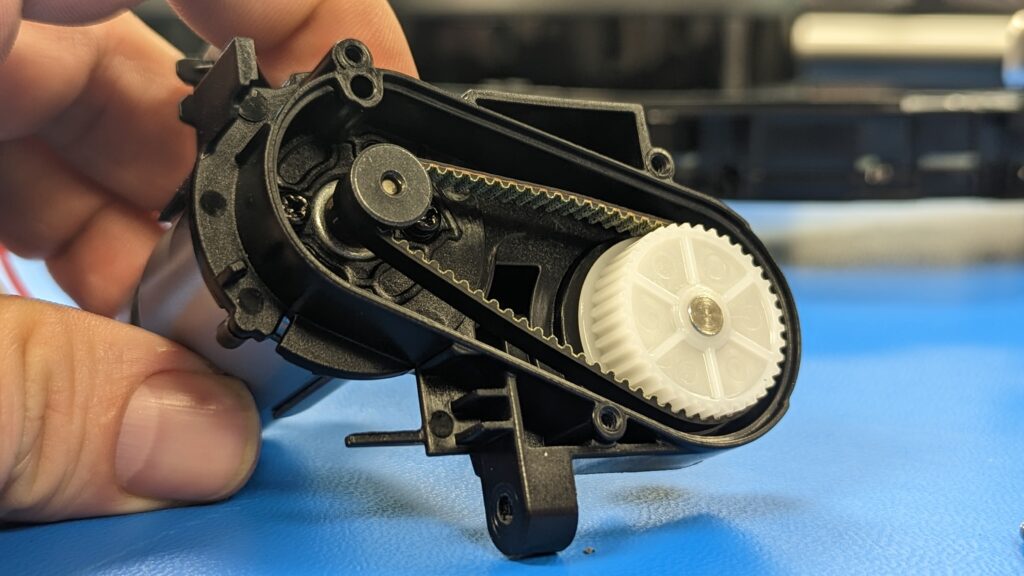

Brush roller drive motor:

A brushed DC motor is used to power the brush roller to sweep up debris from the floor. A belt and pulley system is employed in this assembly to set an appropriate gear ratio while reducing the noise compared to a typical geartrain design.

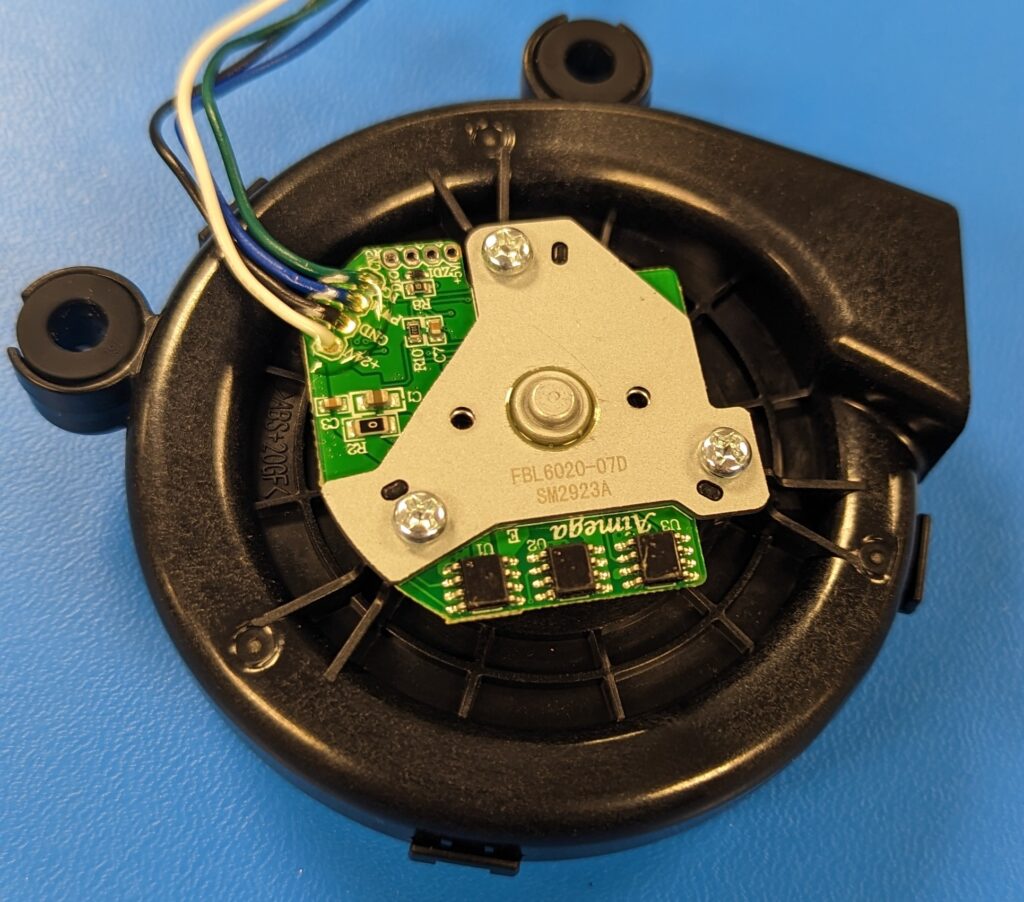

Vacuum blower motor:

A brushless DC motor is used to spin a blower propeller to suck in debris from the brush roller assembly. The air is pulled through the dust bin and filter before reaching the vacuum blower to avoid occlusions and buildup on the blower blades. A brushless motor is used here as the blower motor will see the most revolutions of the entire system. Brushless DC motors have greatly increased lifespans but come at a higher part cost than brushed DC motors.

Side brush sweeper motor:

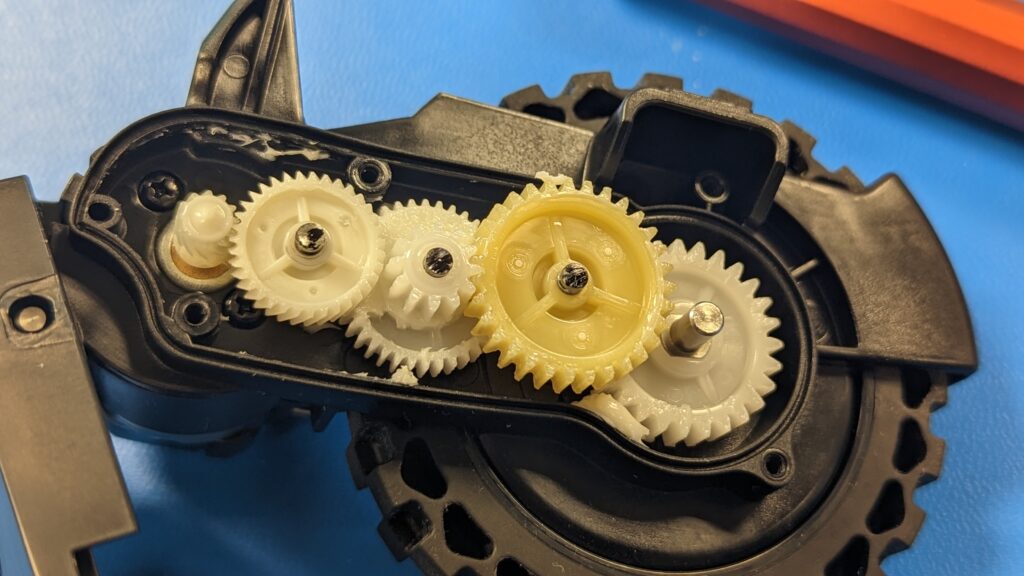

A small, brushed DC motor and geartrain drive a spinning brush to pull in debris that are outside of the main brush roller path.

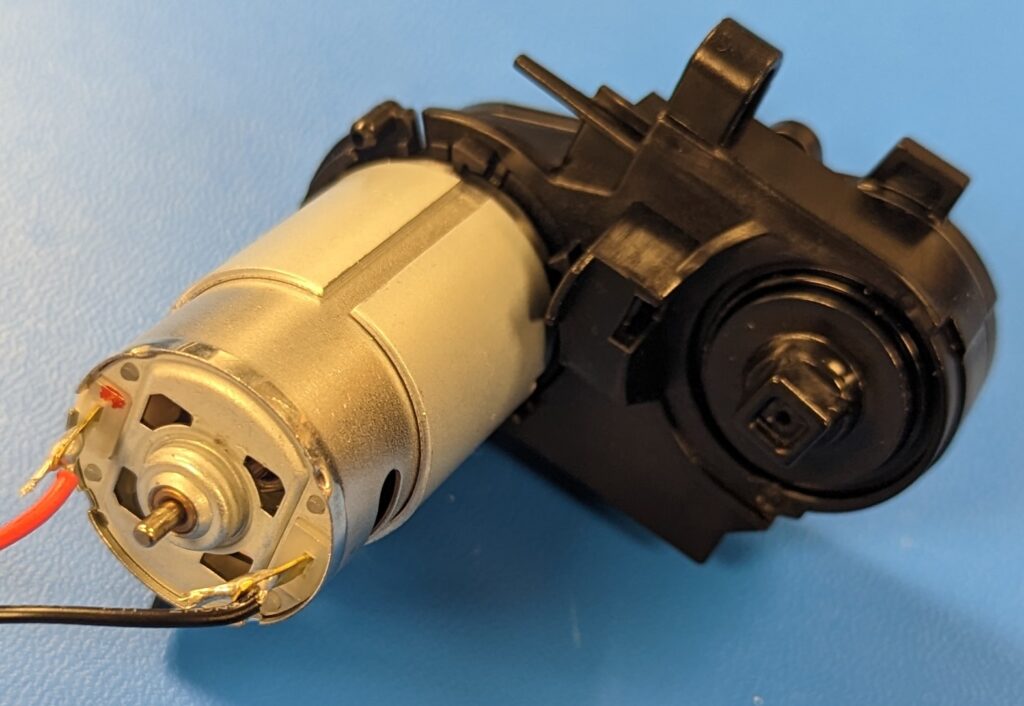

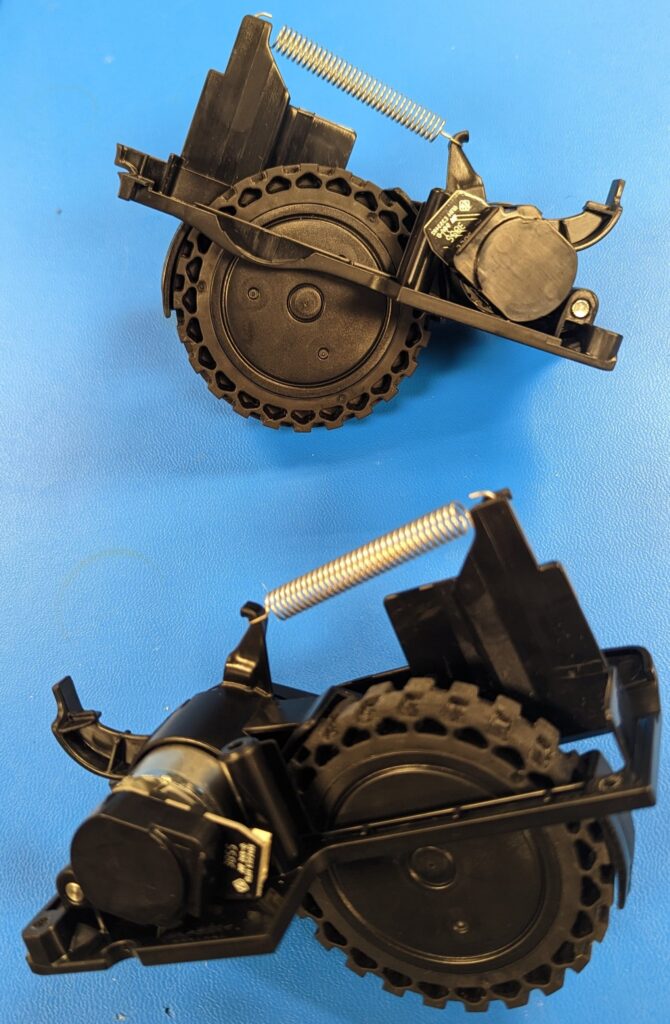

Left/Right wheel drive motors:

A larger, brushed DC motor and geartrain drive each wheel independently. These paired with a single swivel wheel at the front of the unit allow for a dynamic range of motion.

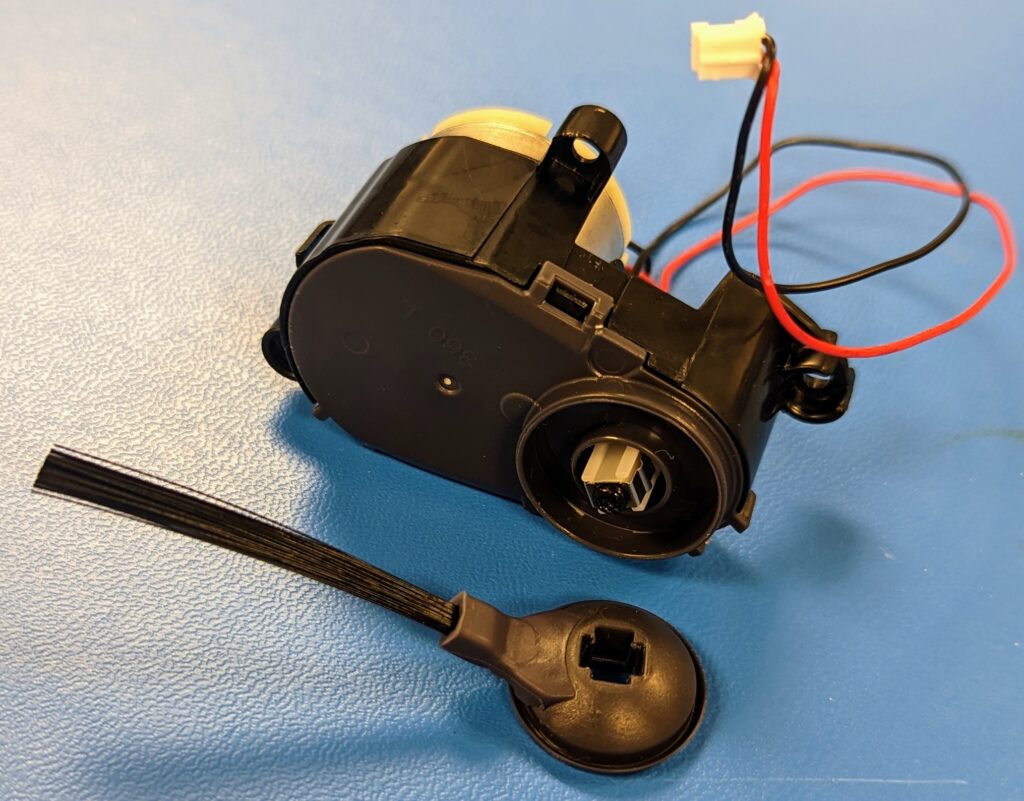

Mop oscillator motor:

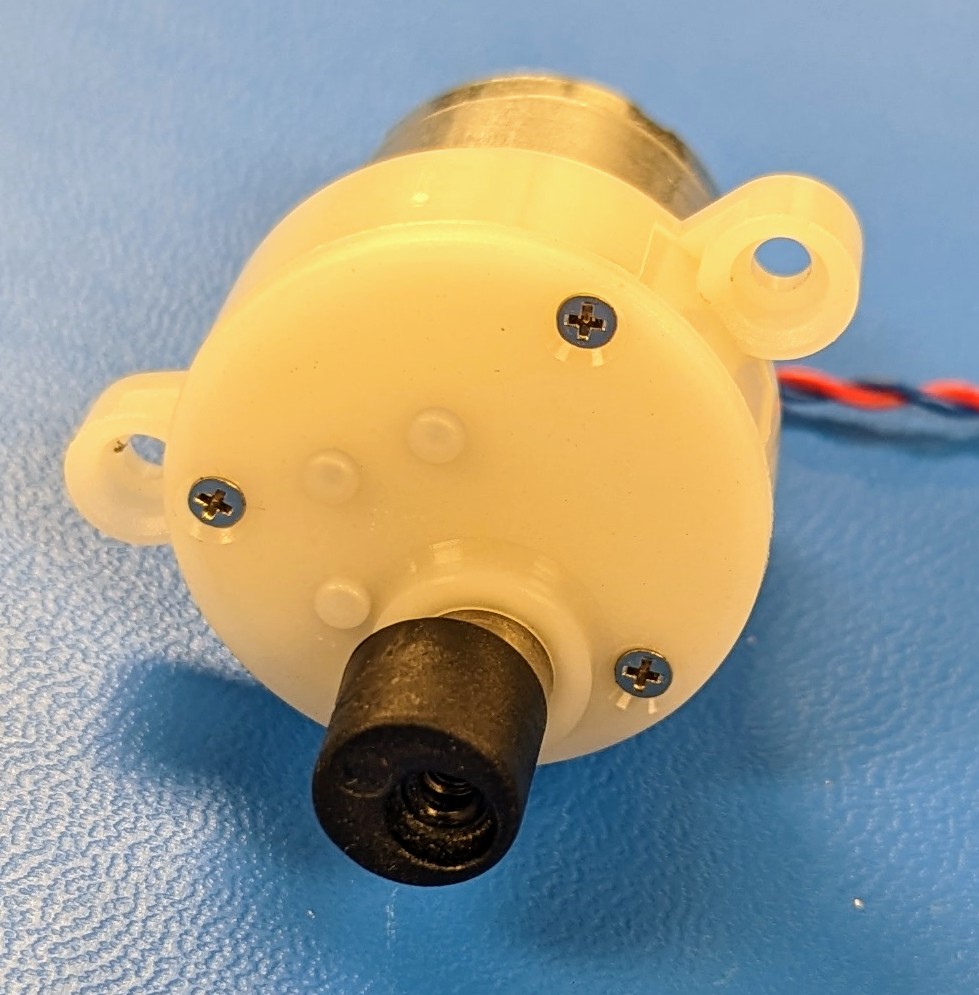

A small, brushed DC gearmotor with an off-center attachment to the shaft. The attachment sits in a slot in the mop attachment. As the off-center attachment spins, the mop is pushed side-to-side to increase mopping efficiency.

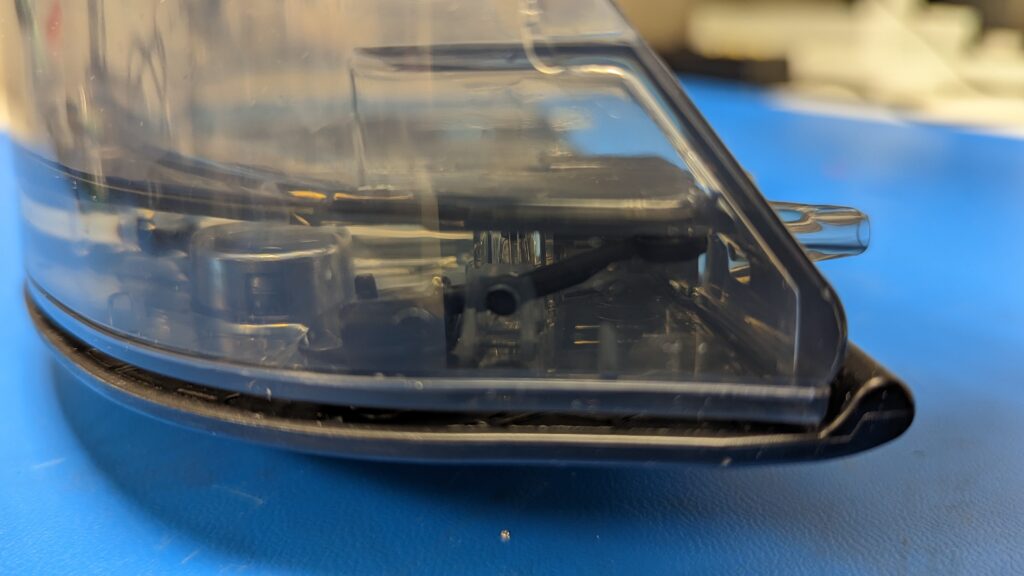

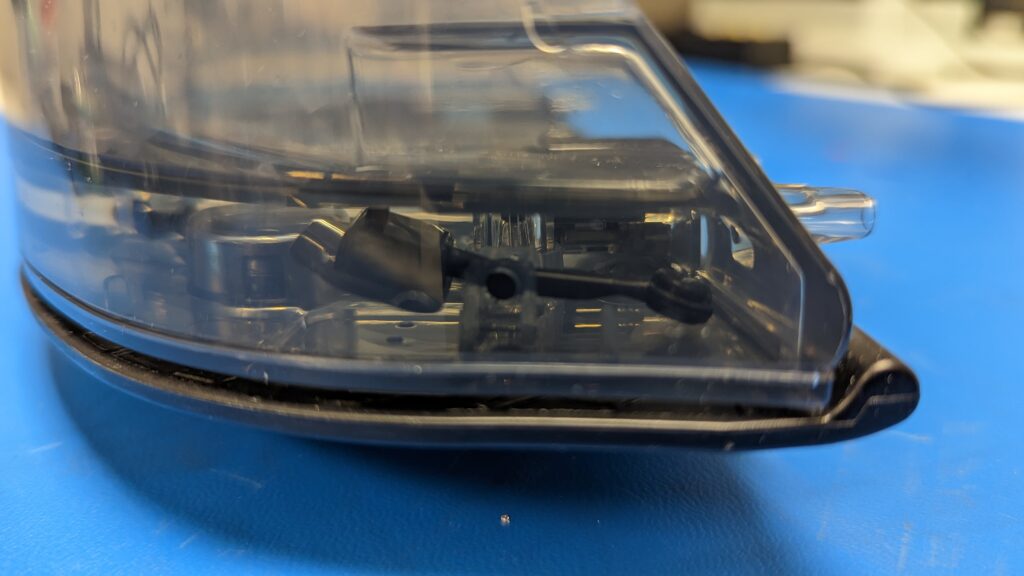

Mop liquid pump:

A solenoid-driven diaphragm pump is used to move liquid from the reservoir tank to the mopping head. The liquid is simultaneously sucked from the reservoir and pumped right back to the mopping reservoir assembly and to three wetting locations. The pump is located within the main body of the vacuum, likely to avoid needing electrical contacts on the mopping assembly to power an on-board pump which would add cost and complexity.

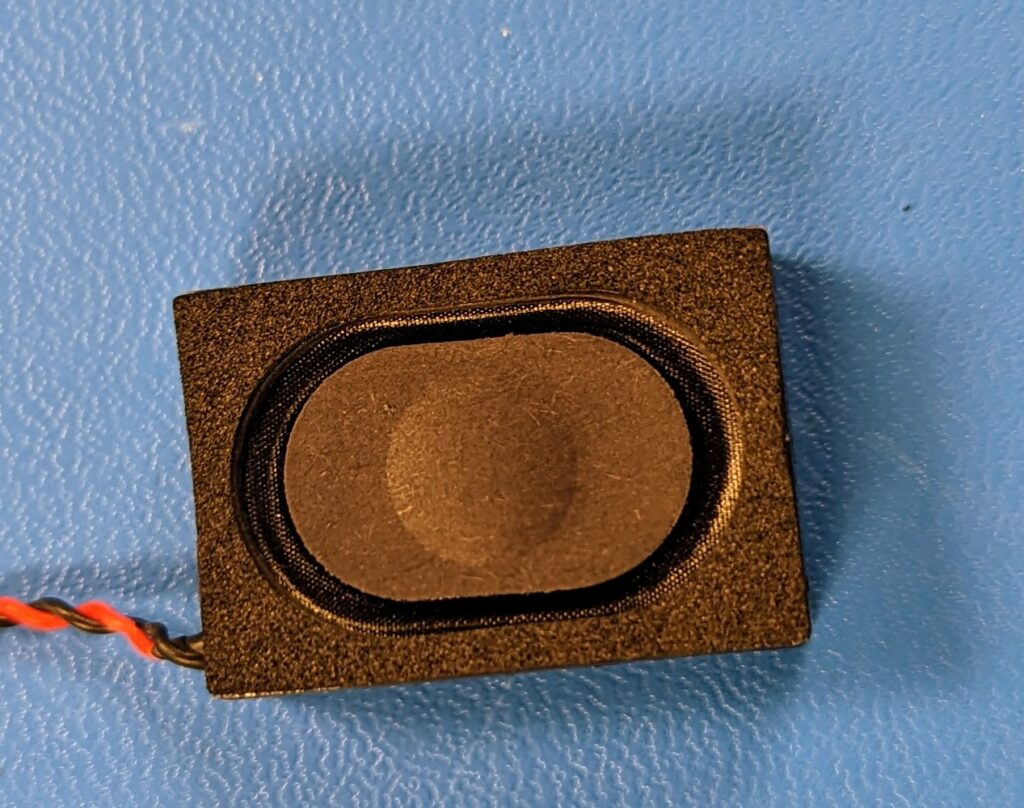

Embedded speaker:

While not typically thought of as a moving component, speakers are small voice coils that oscillate at very high frequencies to produce sounds. The speaker is embedded in these devices to notify the user when commands have been accepted, when errors have occurred, and when operations have been completed.

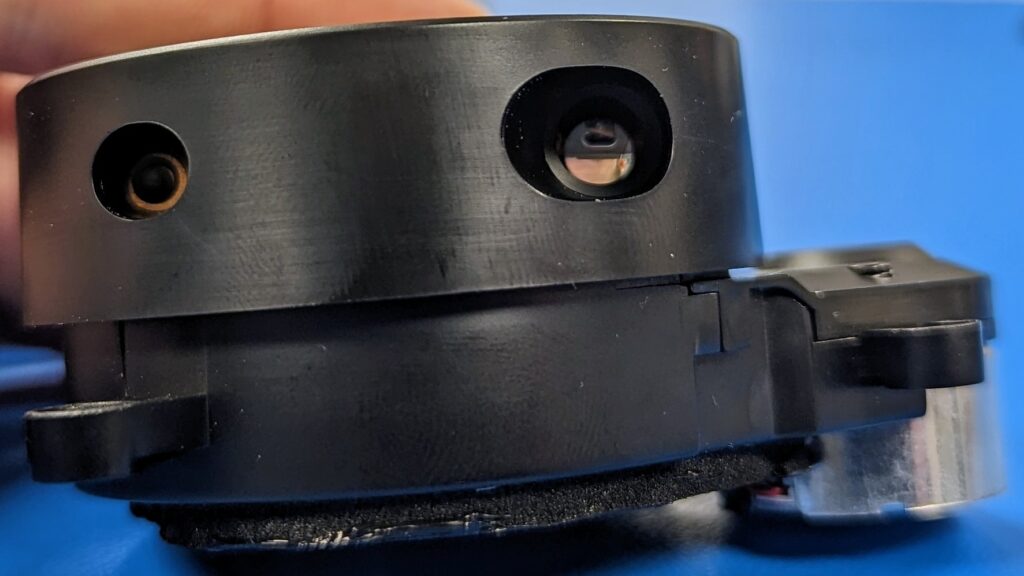

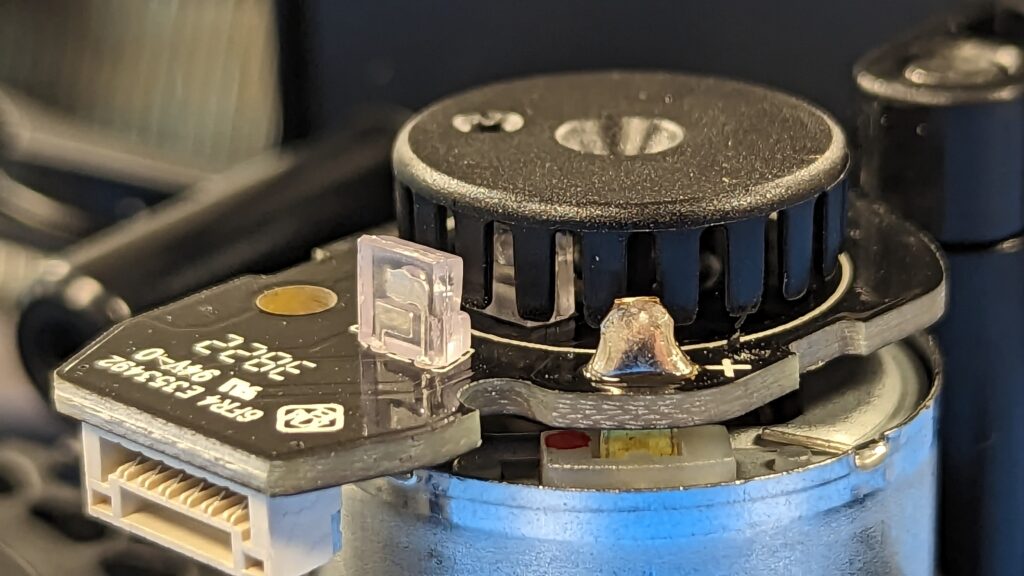

LIDAR (Light Detection and Ranging) motor:

This motor is used to spin the laser and receiver of the LIDAR system. This is used to measure the distance of objects from the robot and is used to generate a 3D map of the environment around it.

Feedback Components (Sensors)

Robot vacuums typically use a combination of sensors to navigate and clean a space effectively. The sensors and this Shark vacuum include:

Buttons:

While the user interface (UI) for this device is mainly controlled via IoT technology (phone/tablet apps and connected smart devices such as Google Assistant and Amazon Alexa), there are still 2 buttons on the top of the device and the central top post can be rotated for when you want to control the device manually.

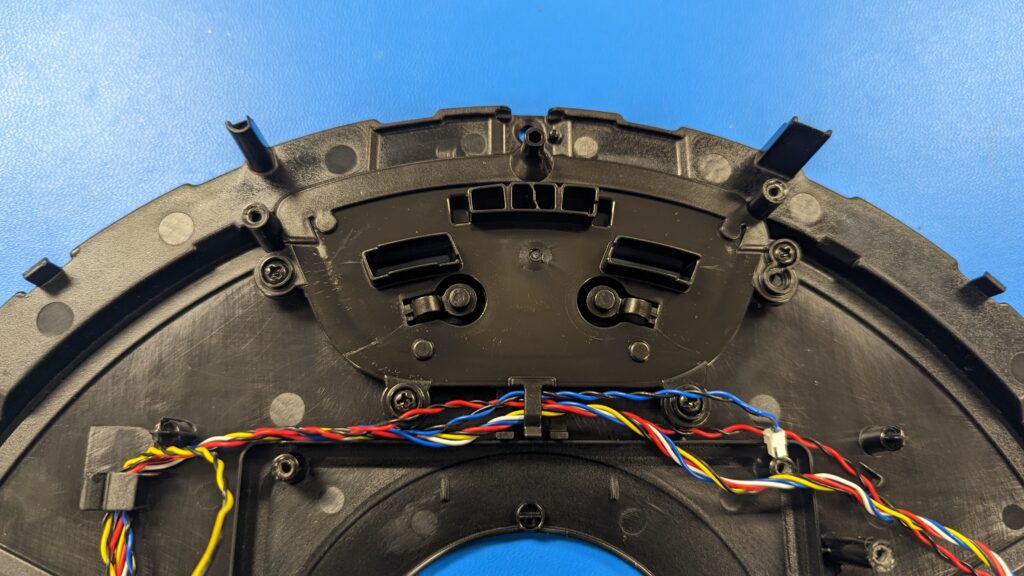

UI Buttons Top

UI Buttons Bottom

UI Buttons on PCBA

Infrared sensors:

These sensors help the robot vacuum detect obstacles and avoid collisions. They work by emitting infrared light and measuring the time it takes for the light to bounce back, allowing the robot to calculate the distance to an obstacle.

LIDAR:

A remote sensing technology that uses lasers to measure distances and create high-resolution 3D maps of objects and environments. LIDAR works by emitting a laser beam, which bounces off objects and returns to the LIDAR sensor. The time it takes for the laser to return is used to calculate the distance between the LIDAR sensor and the object. By scanning the laser in different directions and combining the distance measurements, LIDAR can create a 3D map of the environment.

Cliff sensors:

These sensors are used to detect drops, such as stairs or ledges, and prevent the robot from falling. They typically use infrared or sonar technology to measure the distance between the robot and the floor.

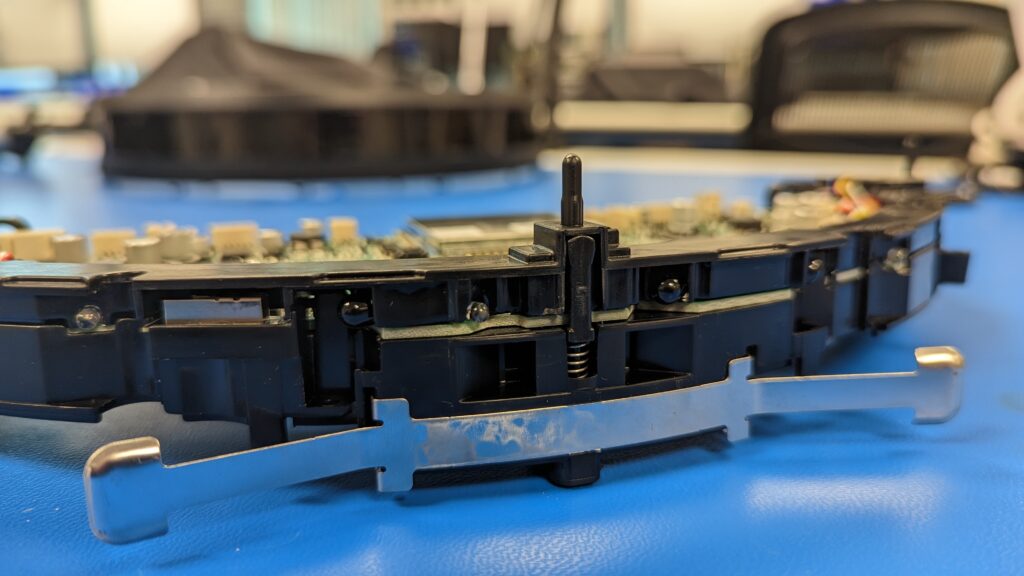

Bump sensors:

These sensors (switches) are used to detect physical collisions with objects in the environment. They are located behind the front bumper of the robot and help the robot avoid obstacles and navigate around them.

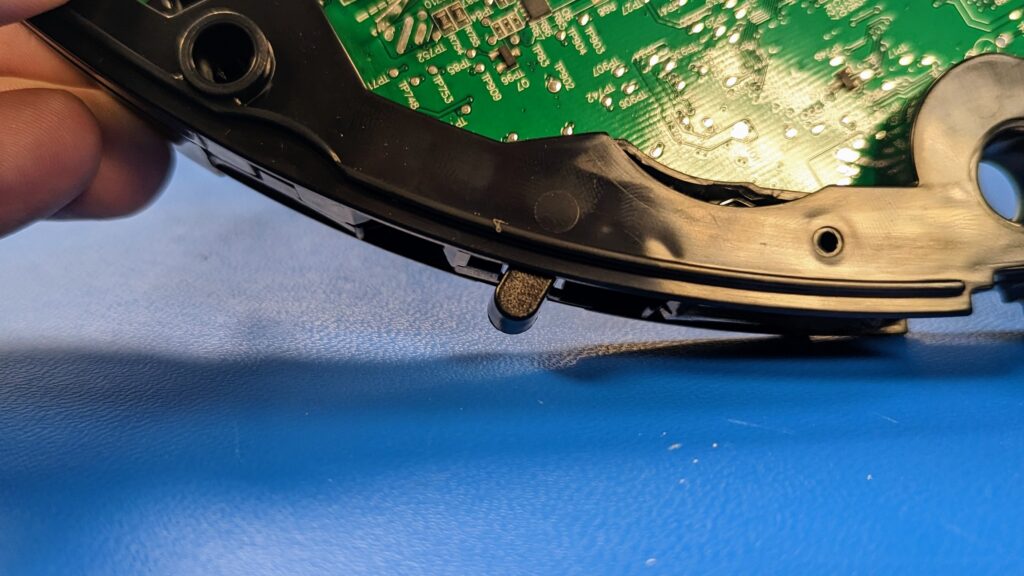

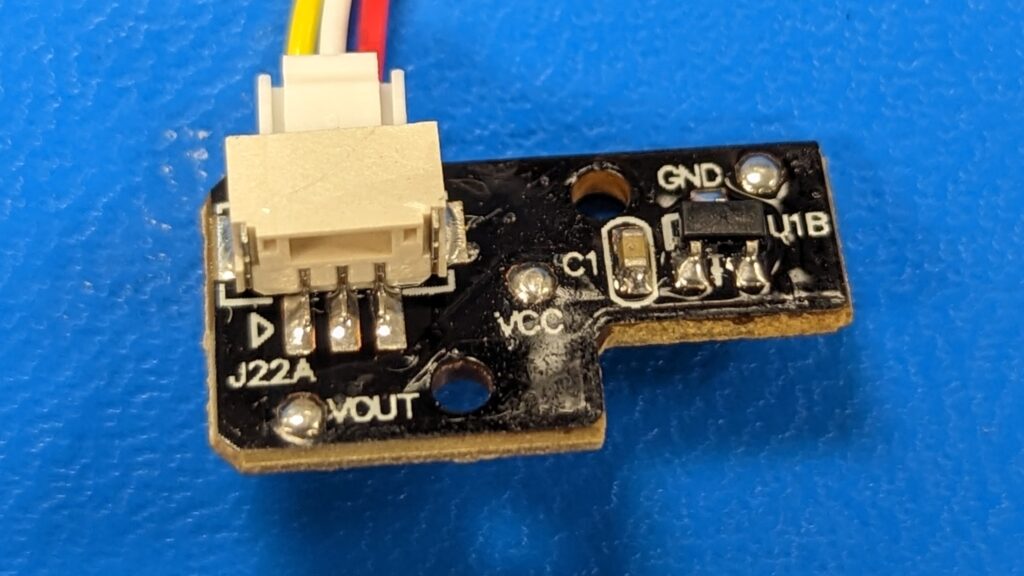

Wheel encoders:

These sensors track the movement of the robot’s wheels and help the robot measure distance and direction. These encoders use a light emitter and detector. As the motor spins the light is blocked by each tooth in the encoder disk which can be used to determine speed and position of the motor.

Mop liquid level sensor:

This is used to detect that there is fluid in the mop storage tank during use. In this device, a non-contact sensor is used to detect the liquid. This is a hall effect sensor which detects when a magnetic field is moved into its proximity. A small float inside of the liquid tank lifts a magnet close to the sensor when the tank becomes empty.

|

|

|

Overall, the combination of these sensors allows the robot vacuum to navigate and clean a space effectively and efficiently.

Shark AI Ultra Robot Teardown Conclusions

Robot vacuum cleaners have come a long way in just the last few years. The introduction of AI and LIDAR along with a myriad of other sensors has boosted the effectiveness of this vacuum to another level. IoT integration allows this device to seamlessly integrate into ismart homes with some simple setup on a smartphone or tablet. The days of a robot vacuum randomly bumping around your home in hopes that it covers all the areas are gone. Long live automated room mapping and smart object detection and avoidance!

With 9 independent motors, 5 IR sensors, 4 cliff sensors, 2 motor encoders, liquid level sensing, 2 bumper sensors and a LIDAR, that is a total of 24 inputs and outputs to this device (not including UI, Wi-Fi, and a multitude of on-board voltage and current sensors)! This robot is a true testament to thorough consumer product design with product life, cost, and efficiency all addressed. All of this makes the Shark AI Ultra 2-in-1 robot vacuum a smart and cost-effective option offering consumers an efficient, effective and time-saving cleaning solution.