When approaching a new product development project, companies have options regarding how they’ll take on the challenge. Depending on the capabilities and needs of an organization, the best development model for a project may range from doing everything internally to fully outsourcing all design, development, and manufacturing.

While the range of options is essentially a continuum, we’ll examine three models that span the range: fully internal development, development by a contract design and manufacturer (CDM), and using a design specialist in conjunction with a contract manufacturer (CM). To compare these models, we’ll look at key factors you should consider when selecting a development model.

Intellectual property protection

If your product is of the “me too” variety, then intellectual property (IP) protection is likely not a concern. You’re taking the time to read this article, so that’s probably not the case. If we assume that IP protection is important for the success of your product, then it’s important to consider the impact of your development model’s ability to protect intellectual property.

The closer you keep your IP, the safer it is. Keeping all product development and manufacturing internal is the safest way to go. The realities of business might invalidate that option, however. If you do outsource, one way to safeguard your IP is by separating design from manufacturing. This provides a firewall, keeping your manufacturer from knowing everything needed to fully replicate your product.

For example, while New Matter chose a low-cost manufacturer in China for production of their MOD-t 3D printer, they chose a design specialist firm (Simplexity) to develop the firmware and electronics for the product. To provide an IP firewall, Simplexity designed a separate set of firmware for use on the manufacturing line that provided only the functionality needed to verify everything worked before shipping the product. The critical product firmware was downloaded by the user during the initialization process. This kept the manufacturer from having everything needed to produce extra units outside of New Matter’s visibility.

Where does your IP security fall on this chart?

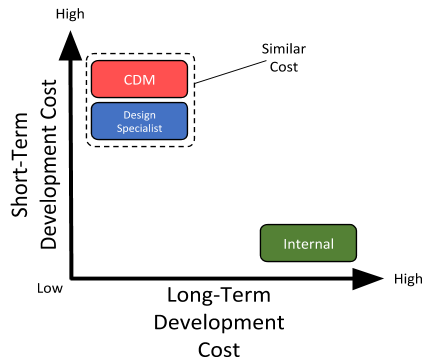

Short-term versus long-term development team cost

A key tradeoff for any company looking to design a product is the cost of the development team. Shipping a successful product requires a myriad of skill sets in various engineering disciplines. In addition, most products require at least some engineers with additional specialties to overcome key technical hurdles. Building and maintaining a high-quality team takes significant time and budget. If your company is going to be producing a series of products based on similar technologies, then it makes sense to staff up internally to avoid the markup associated with outsourcing work.

However, if the product under consideration doesn’t match your long-term needs, or it represents a short-term workload peak, then staffing up internally is likely not the financially prudent option.

While using an external firm’s engineer may cost more per hour than an internal resource, having that cost disappear at the end of the project represents a long-term cost savings. In addition, design specialty firms likely have the technical talent you need today on staff, letting you avoid the time and expense of the candidate search and hiring process. Of course, you can just build up the team internally, then cut everyone at the end of the project. That might work once, but if your company builds a reputation of hiring and firing, you’ll find it harder to hire quality talent in the future.

Where will you spend your development budget?

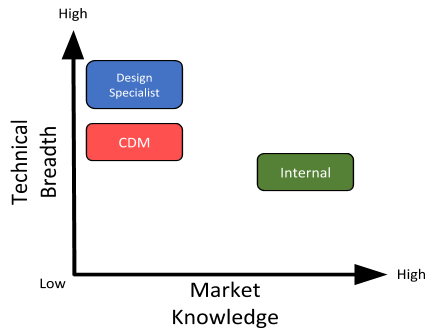

Market knowledge versus technical breadth

Your company is developing a product for a market you know well — a market you and your customers think about every day. The only other companies that know the market even close to as well as you do are your competitors. If market understanding is critical for all your design engineers, then you should probably keep your development in-house.

When you need additional technical skills that you don’t have within your company, you may want to consider bringing in outside design help. In fact, for most products, it’s sufficient to have a good requirements document (requirement specifications and acceptance test specifications), in conjunction with an internal marketing product owner that can interface with an external design team. Both design specialist firms and CDMs can be successful in delivering the right product for your market if the correct documentation and guidance are provided.

Also, a design specialist firm likely has experts in a broader range of technologies than your internal talent and may be able to bring better solutions to the table for your product.

Internal, CDM, or Design Specialist: Where does your enterprise’s expertise lie?

Control versus specification

Related to the discussion of market knowledge and technical specialization above is the concept of design control compared to the work required to create high-quality specification documents. If you manage the project yourself with internal resources, you’ll have very fine-grained control of the work and the final product with low effort. In addition, you can likely get away with less detailed specifications, as an internal team will have a better feel for what’s required. Note that it’s still highly recommended you create detailed requirement and design specification documents. The act of just writing things down does wonders for clearing up miscommunications.

To successfully outsource work, it’s critical to have detailed requirements specifications. The requirements specification document will be your primary means of conveying the needs of the product to the developer. Creating a detailed specification can take a lot of work. It’s a good idea to review and iterate on the document with the design team. Also, realize that there will be new requirements discovered as you learn more about the design. It’s much better to be flexible and iterate than to shoot for 100 percent completeness out of the gate.

Once the specification is written, the workload on the internal team will go down significantly and free up valuable internal resources to focus on projects most critical to your business.

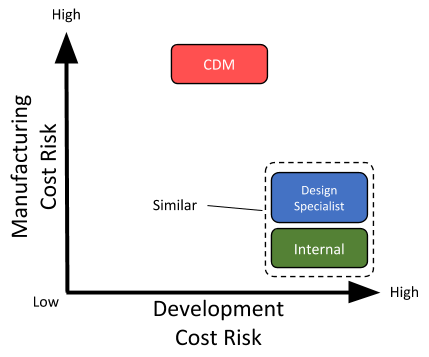

Development cost risk versus manufacturing cost risk

A common tool for reducing financial risk in developing a product with a CDM is to share the development costs and product revenue. In this model, the CDM offers steeply reduced rates for the development engineering in exchange for guaranteed production volumes and a cut of the product revenue. If the product is successful, both organizations win. If not, the financial downside has been shared, too.

While this type of arrangement does reduce one type of financial risk, it increases two other risks to the product development company:

- You’re locked into a single supplier for your manufacturing. It’s very difficult to get all the development knowledge transferred to another manufacturer. Even if you have access to all the engineering drawings, manufacturing process documentation, etc., the team that has intimate knowledge of the project is likely no longer accessible to you. This makes the transfer of production difficult and risky.

- It can be very difficult to realize cost reductions in manufacturing. This is the fabled “fox watching the henhouse” problem. Without an objective observer to keep an eye on the manufacturing costs, CDMs have little incentive to pursue cost reductions. In fact, there’s a conflict of interest, where increased manufacturing costs add to the bottom line of the CDM and help to recoup their development costs.

Using a firm that specializes in product design and design for manufacturability in conjunction with a contract manufacturer provides a different risk profile. A design specialist firm can’t offer the reduced development costs as there’s no backend to make up lost margin. However, that same firm has a vested interest in making sure the client is happy with the manufacturing costs and can act as a trusted third party to keep the CM manufacturing costs in check.

Determining where the cost risk lies on your project can greatly inform the process.

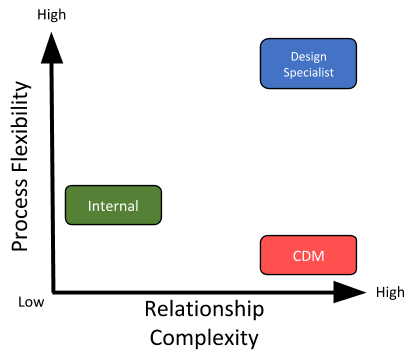

Relationship complexity versus process flexibility

CDMs have an intriguing value proposition. They’re the “one-stop shop” for all your design and manufacturing needs in one business relationship. Plus, their design and manufacturing engineers can work tightly together. It seems reasonable that there will be reduced barriers to communications within a company. In practice, the “one-stop shop” may not be all it’s cracked up to be:

- Running a prototyping/machine shop and/or a manufacturing line is very different than running an engineering design team. Manufacturing of parts is a capital-intensive business. To get a return on that investment, high utilization is required.

- Access to the equipment is likely not as readily available as you would hope, as it must be kept busy. Of course, the flip side is that high availability comes with a cost. If you tour a facility and see lots of idle equipment, consider the overhead costs to cover that expense, and who will be paying for that cost.

- No single company can afford to have the latest and greatest equipment for every possible manufacturing process. However, a one-stop shop has a vested interest in keeping its equipment or lines busy. This leads to a potential conflict of interest where your product may not benefit from using the optimal manufacturing process because that’s not available at your CDM.

Simply put, no single company can be best-in-class at everything. Any firm that specializes should be best-in-class. Simplexity is a top-notch design firm because we focus exclusively on the design of products. We work with other specialty design firms for aspects of product design at which we can’t be the best. For skills such as industrial design or mobile app development, we partner with the best. Over the years, we’ve found that the best companies, both design and CM, are great at communication because their success depends upon it — the feared barriers just don’t exist.

When it comes to precision execution, a design specialist performs better than companies that perform more tasks in the product development cycle.

What’s the best development model?

We’ve discussed several factors that should be considered when selecting the development model for your program. For some projects, doing things internally is the way to go. For other projects, outsourcing your design will make the most sense. Each project and company is unique and will have its own set of challenges. Considering each of the tradeoffs discussed above should help you to make an informed decision.

If you need help understanding the tradeoffs, please contact us. We’d love to understand the challenges of your program and help you define the best model for your product development needs.