In part two of my three-part mechatronics discussion I provided tips for the design of high volume mechatronic systems. In this final entry of the series, I’ll discuss five additional tips for mechatronic system integration of mechatronic systems for high-volume products.

To achieve the optimal cost/performance ratio in any system, the design must be tightly integrated. All of the system components must be working together in harmony, with minimal overlap in function and any excess design margin eliminated. Here are five tips to help you achieve tight design integration in your next mechatronic design:

1. UNDERSTAND THE SYSTEM REQUIREMENTS

It’s extremely difficult to generate the best possible solution to a problem when you don’t know what the problem is. The first thing you need to do in any design is to understand the requirements of the design. Once you understand the requirements, stake out the limits on the specifications and communicate those, so that the whole team is clear on what the system will and will not do. Then focus your design on delivering the all performance you’ve committed to deliver but nothing more. Adding margin will add cost.

In mechatronic systems, the key requirements typically boil down to understanding the motion required, and the loads that must be moved. Make sure you understand all facets of the motion such as move time requirements, masses and inertias, friction loads, external loads and any constraints on the drive train. There’s often opportunities to reduce the size (and cost) of the components required by reducing the peak loads. The closer the peak load is to the average, the better utilization of the parts in the system.

2. UNDERSTAND THE KEY CONSTRAINTS

Just as important as requirements are the constraints on your design. Tight cost goals will manifest in a variety of system constraints. The most common constraints in motion systems design are limits on the electrical inputs to the system: maximum voltage, current, and power draw. Related to those factors are limits on the power dissipation in the power supply and driver so that things do not overheat. In addition, there may be other user related constraints such as velocity limits based on safety requirements, and acceleration limits to minimize vibration.

3. SELECT AND PLACE SENSORS CORRECTLY

It’s surprising how often the selection and placement of sensors causes problems in mechatronic systems. My belief is that this happens because sensors are seen as expensive and receive more than their fair share of cost reduction attention. The fact of the matter is that sensors are your only insight into the operation of the machine. You want to make sure that you’re getting all of the data you need, and that you understand exactly what the sensors are telling you. Recently Simplexity has been pulled into projects with two different customers to resolve critical motion issues that are affecting the ability to ship the product. Both were related to the usage of the sensor. Most motion systems have some type of position encoder for feedback control. The design and use of this sensor greatly affects the ability of the feedback algorithm to control the load as desired.

First, remember that the control system doesn’t really position the load, it positions the encoder. Ideally, you want to encode the thing you care about. However, a common trick is to place an encoder on the motor shaft to take advantage of the gear ratio for increased resolution. When that is done, gear train backlash and gear manufacturing errors will induce a difference between the position estimated by the motor mounted encoder and the actual load position. There are workarounds available, but for fast, high accuracy load placement, you’ll want to directly encode the load.

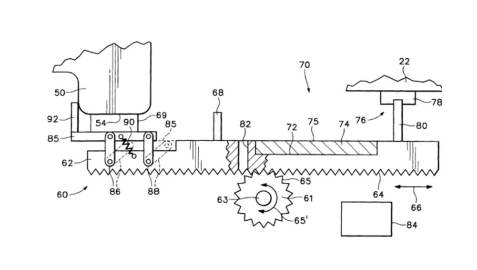

Example: I was developing the servo system for an ink-cartridge cleaning station in an ink-jet printer. The service station used a rack and pinion mechanism to drive a set of rubber wipers back and forth over the nozzles plate of the cartridge to remove excess ink than can pool on the plate. To reduce cost in the system, a rotary encoder was placed in the tail of the motor shaft. The required stopping accuracy of the wipers was ± 0.5 mm. The overall backlash in the system was approximately 2 mm. In order to achieve the stopping accuracy required, additional calibration algorithms were required to estimate and account for the backlash.

Second, make sure the encoder system has sufficient resolution. Feedback control systems are not perfect. You should expect to stop with non-zero error unless you’re able to build a very stiff system. Design in enough encoder resolution to support a reasonable stopping error. Also, if velocity control is important, you’ll need sufficient velocity resolution (encoder counts per servo sample period) to measure and correct for velocity deviations before the velocity is out of spec.

Example of velocity resolution: Assume you’ve designed a system that delivers 1000 encoder counts per millimeter of linear travel for your load. Also assume that the frequency chosen for the servo algorithm update is 500 Hz. Since the minimum position change that can be detected is one encoder count, and that is checked every servo sample, the velocity resolution is: 1/1000 mm/count / 1/500 sec/sample = 0.5 mm/sec. This system is incapable of detecting a velocity change less than 0.5 mm/sec at each sample. If the velocity control specification requires velocity deviations to be less than 0.5 mm/sec, either the interrupt rate or the encoder resolution will need to be modified.

Finally, make sure that you have the sensors you need for other tasks like detecting home position and measuring motor current. These are not always needed, but for some applications they are critical.

4. MATCH THE SYSTEMS DRIVE COMPONENT INTERFACES

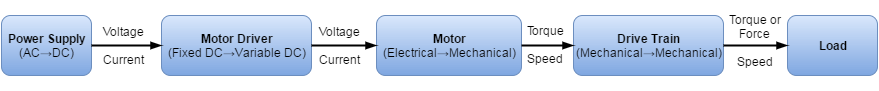

The diagram below shows how power flows and is converted as it travels from the power supply to the load in a typical high volume mechatronic motion system.

Core to the concept of an optimized cost/performance ratio for a mechatronic motion system is properly matching your system drive component interfaces. Each block of the diagram must be designed so that it performs its power conversion at the lowest possible cost, without violating design constraints. Ideally, the amount of design margin in each block is roughly similar. However, there may be cases where the cost of adding margin is much higher in one component than another. In those cases, the lowest cost design will require adding cost to the lower cost components so that you can achieve a greater cost savings in the more expensive components.

It is important to note that these blocks belong to different traditional engineering disciplines. In order to shift the costs as described above, the design must be treated as a mechatronic system. When treated as such, the mechatronic system engineer has the flexibility to reallocate cost across the system to achieve the best overall product cost structure.

5. INTEGRATE FROM THE START

Finally, it’s important to treat the system design problem with a mechatronic mindset from the start. If the design starts with electrical and mechanical teams going off and independently creating product architectures, the job of mechatronic system integration will be much more difficult, and the cost/performance ratio of the design will suffer. Make sure you have an experienced mechatronics engineer on your product architecture team when you start your design process.

It’s easy for me to list these five guidelines for mechatronic system integration, but it’s hard work to implement them and get them right. These hints are based on best practices for systems engineering, and were refined over many years of developing best-in-class price/performance ratios for high volume mechatronic motion systems. I strongly believe in them, and I believe getting these things right will give you a great design.

Wanna learn more about motion control systems and mechatronic system integration?

Check out: