After seeing a friend at Illumina post a company-wide request for intubation boxes for area hospitals based on an open source design concept, I knew that Simplexity would be happy to assist in any way possible to help the amazing healthcare workers on the frontlines. When your engineering team has the skills needed to help and the desire to make a difference in their community it is easy to say YES to volunteering for a project like building hospital intubation boxes that can save lives!

So what is an intubation box anyway?

Intubation Boxes, described by Dr. Benjamin Reeser, MD and the Intubation Box team are protection intended to mitigate potential contamination to healthcare workers from airborne virus during the process of inserting an intubation tube for ventilators as they assist patients being treated for contagious diseases.

The Intubation Box is an inexpensive and reusable protective device originally designed by Dr. Hsien Yung Lai in Taiwan to protect healthcare providers when intubating Covid-19 patients.

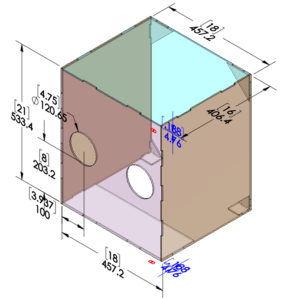

The Intubation Box works by sitting over the head and shoulders of a COVID-19 patient as they are intubated by a healthcare provider. The acrylic box acts as a protective shield between the patient and medical provider, with the intent of reducing the healthcare provider’s exposure to Coronavirus (COVID-19). After each intubation, the box can be cleaned with a bleach or alcohol solution. Ie. Sani-Cloth wipes.

Intubation and the steps leading up to it are some of the highest-risk moments for COVID-19 spread to healthcare workers and other patients†

The partnership between Simplexity and Illumina

After a quick call with Illumina, a global genomics leader, our team stepped in to design the box to be fabricated from acrylic using Illumina’s CO2 laser.

Interest in the project grew after a design review and two sizes of prototypes were delivered to one of the hospitals. The team received emergency FDA approval and Illumina stepped in and supplied $10K for materials.

Illumina and Simplexity employees worked on ordering material, fabricating panels, supplying assembly labor, and coordinating with area hospitals to deliver finished products.

While I worked on the design and coordination between Illumina and Simplexity, the local team in San Diego immediately started on the many additional aspects of the build. Minh Duong was busy cutting down large 4’x8’ acrylic panels for Illumina’s laser bed while Jim Burrow was quick to assemble the boxes with Tony Dean who also coordinated the project on site.

After the first round building hospital intubation boxes

- So far 4 Hospitals have ordered boxes and 24 boxes have been delivered with a remaining 16 boxes on order.

- The second round of prototypes were designed based on design feedback from Kaiser Permanente hospitals.

- As orders continue, a volunteer team is working on design, fabrication, and distribution of box shields for donation to local hospitals.

- The volunteer team continues to work on materials sourcing and acquisition for another round of builds.

The project to design, fabricate, and donate box shields to local hospitals is a team effort with volunteers from Illumina and Simplexity

The Simplexity team is proud to be a part of the joint effort to bring intubation boxes to area hospitals to better protect our healthcare heroes. We thank Illumina for including us in this urgent project and for generously supplying the materials needed to get this project in the hands of those that need every extra ounce of protection they can get to stay safe and healthy so they can continue to be of service to our community.

† https://canadiem.org/recommendations-for-covid-19-intubation-an-infographic/