This past Halloween, Simplexity employees were given the opportunity to showcase their engineering expertise in the form of a friendly competition. The task was clear: “Design and build a Halloween-themed mechatronic contraption, decoration, or other physical moving item that can be shared on social media by video.” Each team of two to five competitors had only eighteen days to create their masterpiece.

The “SpiderMech” team quickly formed, assembling two Systems Engineers, two Mechanical Engineers, and one Mechanical/Electrical Technician. Members had expertise in mechatronic systems development, SolidWorks design, electronics, coding, fabrication, and more. Competing teams such as the 2nd place winners Hell’s Angels and similarly diverse teams formed throughout Simplexity across all four offices in San Diego, Seattle, Vancouver, and the San Francisco Bay Area.

Simplexity Office Locations

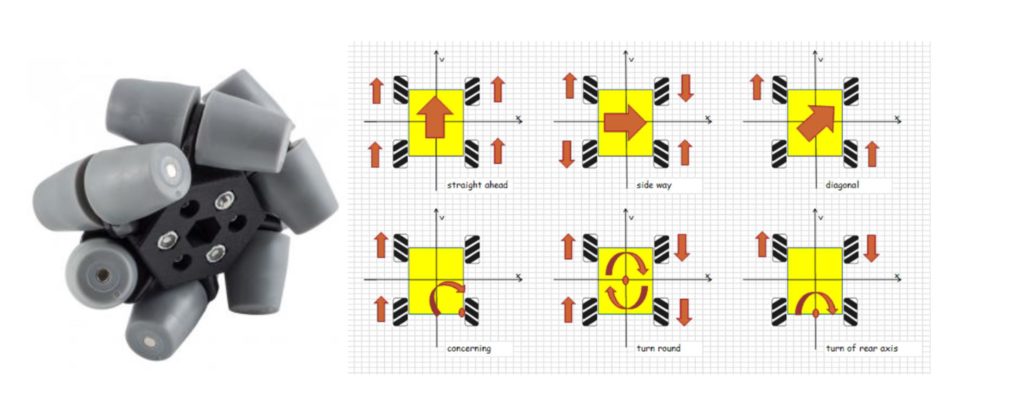

Kicking off the design process, the SpiderMech team began brainstorming ideas that met the design prompt. Keeping true to their namesake, the team settled on an idea to develop a mechatronic candy bowl, styled after a spider, that would “run” away from an unsuspecting trick-or-treater. As a back-up, if someone got too close, the spider would spray silly string web at its unlucky victim! This path was partially inspired by the technologies that were available to the team members. Specifically, one member had a set of four Vex Robotics “Mecanum” wheels, which allow a robot to move in any direction. This is accomplished by means of angled rollers that make up the wheel tread, paired with different combinations of rotation directions on independent drive axes.

Mecanum Wheels – Roboteq.com

These wheels paired with an array of ultrasonic sensors, an Arduino, and a custom motor driver board to detect the position of an incoming trick-or-treater and respond with the correct combination of drive directions to move directly away from the subject.

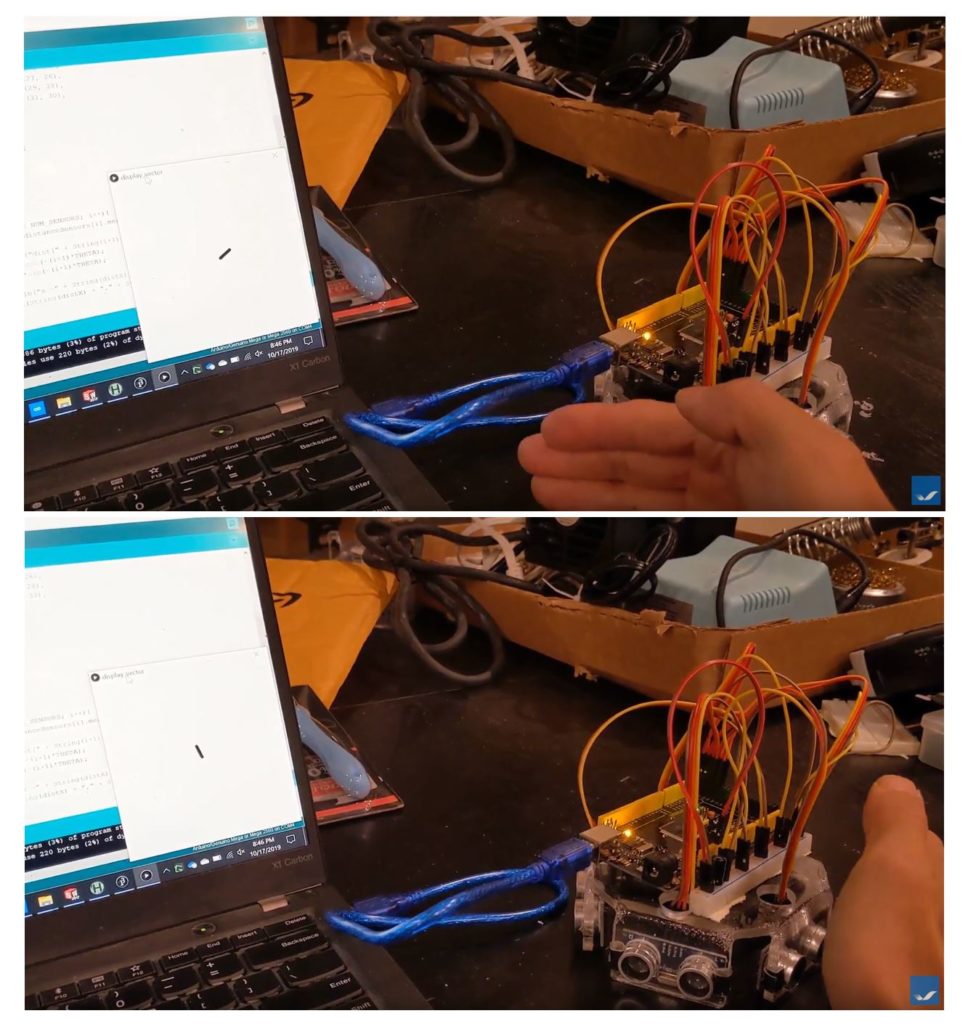

Demonstrating Ultrasonic Sensor Vector Plot

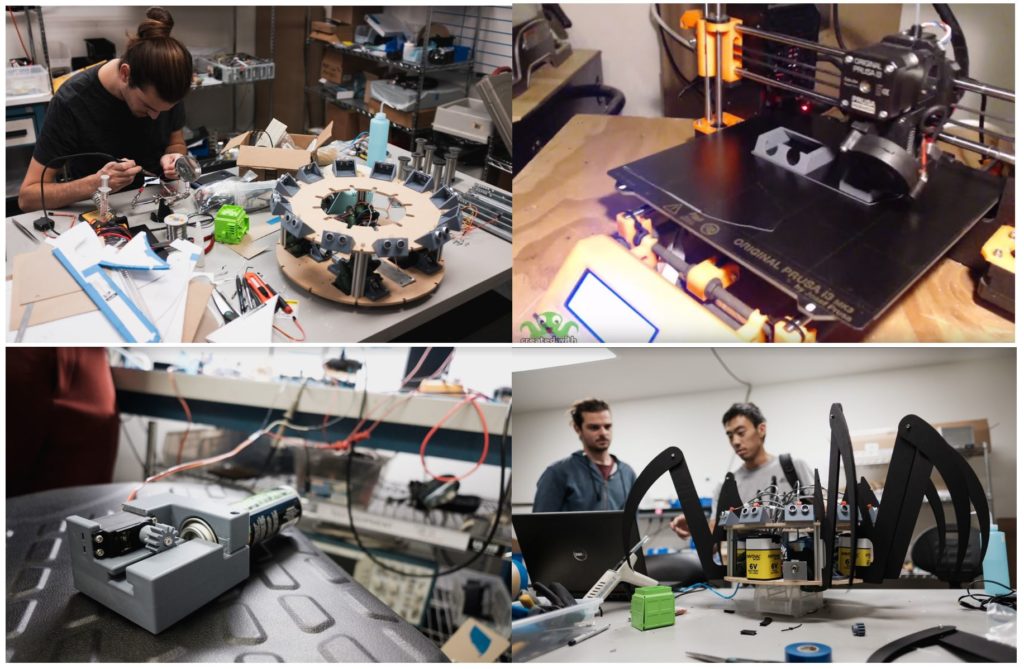

Thankfully, Simplexity is full of “makers” with home shops lined with tools and materials. The team was also able to scrounge up four DC motors, a dozen ultrasonic sensors, Arduinos, and more. Members quickly identified components and ordered them to be delivered in parallel to the design. This included wheel bearings, a giant metal mixing bowl to hold candy, silly string cans for the web shooter, ¼” MDF for the two main frame pieces, and black foam core for the cosmetic legs.

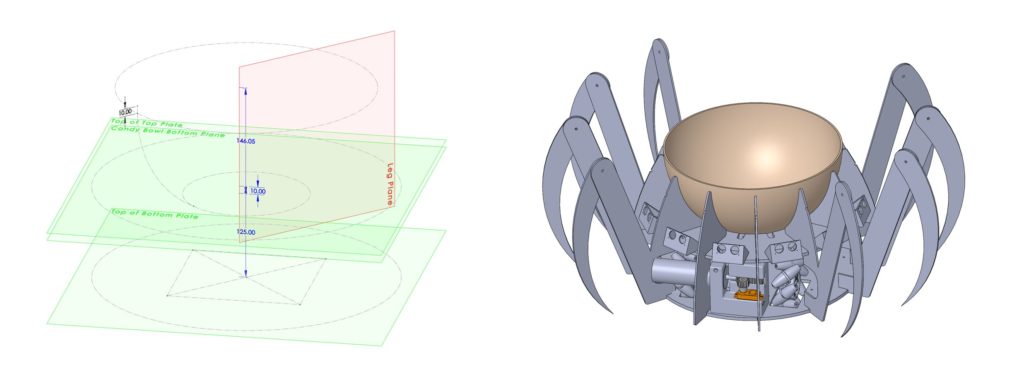

Once the initial concept sketches were complete and parts were on order, 3D CAD development and systems design began. Due to the potentially volatile nature of this rapid design process and the lack of availability of 3D CAD models for many of the purchased components (Amazon doesn’t tend to share CAD for their mixing bowls!), the SolidWorks model of the Spider Mech was built using a “master model” approach. In a nutshell, this means that every component is driven off of one “master” component that is made up of many planes, axes, and sketches that define key interfaces in the design. This allowed on-the-fly scalability of the design as more information came in like mixing bowl dimensions, battery sizing, etc. Without the “master model,” each part would need to be updated individually for every change that was made, time that couldn’t be wasted on such a tight schedule.

SolidWorks CAD Master Model

The Systems team broke the design up into two primary subsystems: sensing and driving. Each member got to work developing one of these subsystems to a point that they could be evaluated individually in a benchtop setting before being installed into the top-level system.

The sensing subsystem treated each ultrasonic sensor output as a vector, where the magnitude was the distance from the sensor, and the direction was determined by its angle on the spider body. By taking the sum of all these sensor vectors, the spider knew how close and from what direction an enemy was approaching.

The drive system then took this information as an input and responded by driving the combination of axes and directions that would move the Spider Mech away from the sensed object.

Of course, the relative position of the sensed object would change as the Spider Mech moved, so it needed to assess position and act on that data at a fairly high frequency. The sensors were polled and motors were updated 10 times a second. To prevent the motion from getting too jittery, a simple exponential filter was implemented, giving the team a single knob to tune to make the spider more or less reactive.

The final piece to the puzzle was communicating with the spider. There were some obvious complications with tethering a computer to a robot that wants to run away from you. Instead, the team used a bluetooth low-energy transceiver and a mobile app to communicate with the spider. With the tether gone, the team could even program different “modes” that could be commanded on the fly, including the ever-entertaining “attack” mode that reversed the spider’s fight-or-flight instinct.

Once the team was confident in subsystem test performance and top-level CAD, fabrication began. The tight timeline dictated many of the fabrication methods, which relied heavily on rapid prototype processes like 3D printing, laser cutting, and machining of common materials. Structural fastening was done by means of self-tapping screws, and non-structural fastening by means of hot glue. Assemblies were designed to allow for loose fabrication tolerances and high part-to-part variation.

After some bench testing and debug, all functions were working as expected, with a few exceptions. The silly string, for example, was designed to be mounted horizontally. It turns out that silly string cans do not behave well in this orientation, so this posed some reliability concerns. Another observation during testing was that the three 6V batteries did not allow the drive speeds the team was hoping for. After checking on the system parameters, the team wired in an additional 6V battery, increasing our speed by roughly 30%.

After completing bench testing and finishing installation of cosmetic components, “Buy-off” testing was executed using a nefarious trick-or-treating test subject. This test along with the whole process was documented in the team’s contest submission video, below.

To be fair, the final Spider Mech would have a hard time escaping a full-grown adult in an Incredibles onesie. As a proof-of-concept prototype, though, it certainly has some serious potential to frustrate some trick-or-treating kids trying to steal more than their fair share of candy!

This Halloween Mechatronics Competition was a fun opportunity for Simplexity employees to apply our design expertise to something that could share some holiday cheer with our colleagues, friends, and families. To learn more about Simplexity’s expertise in systems design and the markets that we serve (which do not include mechatronic Halloween decorations), check out this page.