Embarking on the journey from prototype to mass production is a pivotal stage for any product. Many entrepreneurs may wonder why New Product Introduction (NPI) services are crucial to this process. In this blog, we will explore the reasons why going straight to a contract manufacturer might not be the most efficient route and how Simplexity’s NPI services can significantly improve the success of your product launch.

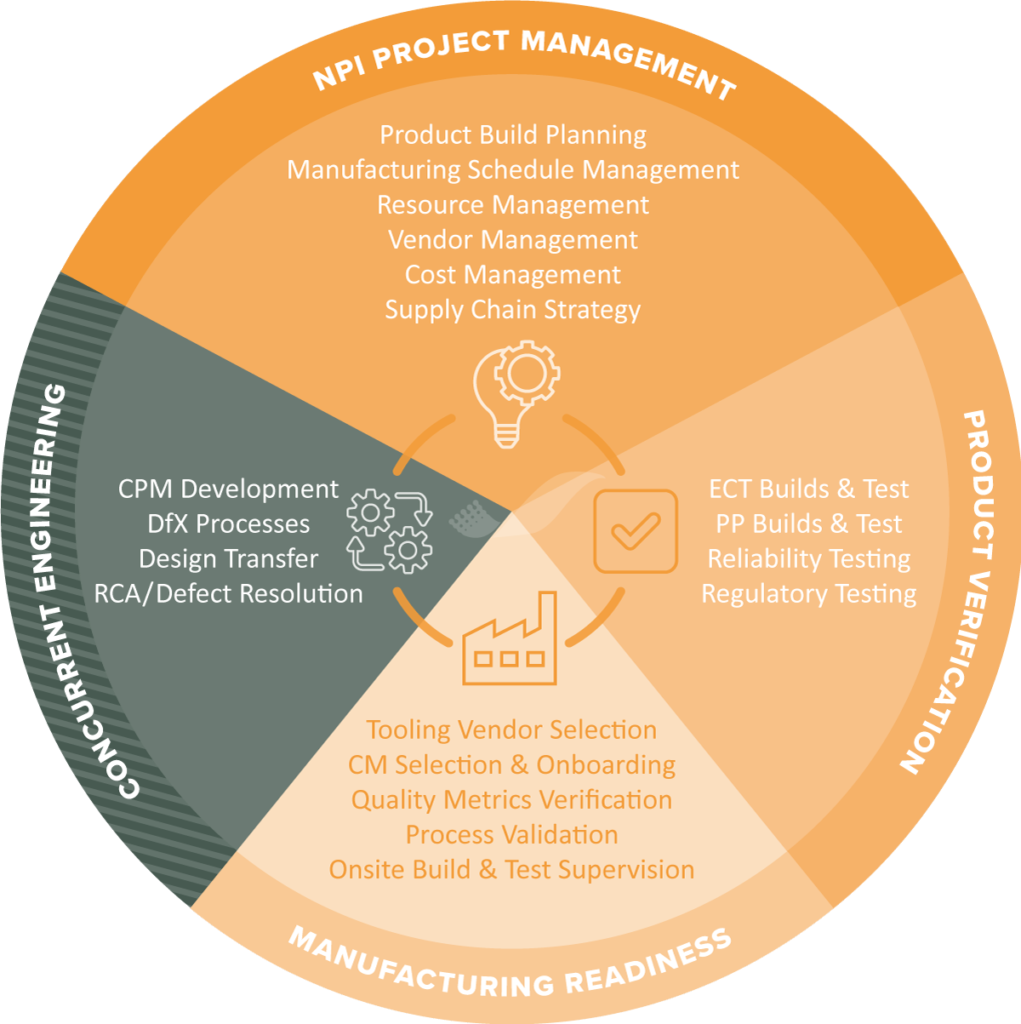

Simplexity’s New Product Introduction

We are often asked, “Why can’t I take my prototype and go straight to a contract manufacturer? Do I really need NPI services?”

One of the biggest benefits to using Simplexity’s NPI services is that you can launch your product quicker, save money, and ensure higher product quality.

With a contract manufacturer (CM) chosen, you might expect that your product will be ready to build as soon as the prototype is complete. Companies without NPI engineers are often surprised to learn that it can take 6 months or more to fully onboard their product at a CM and begin initial pilot builds.

Why is this? It takes time to…

- Resolve contract paperwork

- Import the design documentation

- Place orders, including validating supplier list

- Establish relationships with any critical new suppliers.

- Manage inventory, especially if inventory is consigned

- Iron out details for product traceability (component serialization)

- Transfer assembly and QC equipment & processes

- Develop a Quality plan, including inspection and testing

- Develop manufacturing processes: line layout, assembly instructions, training materials, packaging procedures

How can Simplexity help?

During CM onboarding, we can be working in parallel to…

Shorten your timeline:

- We determine the process workflow and document work instructions for later incorporation at the CM.

- We design and develop assembly fixtures to streamline the build and ensure consistency. This may include process development, such as adhesive bonding.

- We train the CM on the particulars of the design, either at our facility or theirs.

Offer you cost savings:

- We host engineering builds and evaluate the design and the assembly process. Redesigns are much faster and cost significantly less if they are addressed before transfer to manufacturing.

- We perform verification testing. Our engineers get to the root cause of issues and resolve them before you find yourself in a “line down” situation at a CM.

- Our DFM and DFA processes look for long term improvements, especially in areas previously neglected (Hint: Cable harness design and routing are often ignored until too late and can cost you more money down the line!)

- We transition your product from low volume to high volume part design, such as injection molded or die cast parts, and help schedule the rollout of those high-volume parts. Doing so helps you improve your product COGS.

Ensure quality:

- We help you create, or update required design control documents. Requirements Traceability, Risk Management Plan, V&V, FMEA may need to be in place before the builds begin. This task becomes even more critical for an FDA registered medical device.

- We drive test planning, coordinating how and when each stage of testing may occur.

- We design and develop QC tools to guarantee builds meet quality goals. Tools may be for incoming inspection, in-line assembly, or end of line. Our tools are capable of exporting data to databases for offsite monitoring by your team.

In the complex journey from prototype to mass production, Simplexity’s NPI services emerge as a valuable partner, helping you save time, money, and ensuring the highest product quality. By addressing crucial aspects of the manufacturing process in parallel with CM onboarding, Simplexity sets the stage for a successful product launch. Check out our full table of Individual NPI service values and benefits to help you get your next innovation to market.

Choosing NPI services is not just about efficiency; it’s about making an investment in the long-term success of your product. Contact us to learn more about how we can help you with your project!