Case Study: HP Officejet Pro X

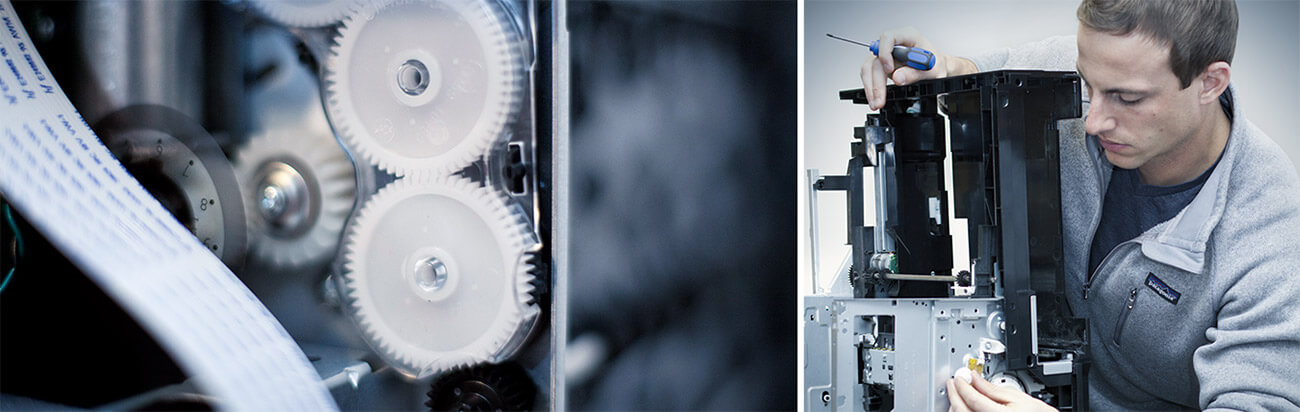

Helping HP develop a page wide office printer that is twice the speed and half the price of the color laser.

In the HP Officejet Pro X, Page Wide Technology consists of a stationary array of 42,240 nozzles that deliver pigmented ink to a moving page. HP’s unique Backscatter Drop Detection, its print head servicing routines, and its nozzle substitution algorithms ensure professional quality printing over a wide range of operating conditions.

What We Did

Simplexity engineers were involved with the product from early architecture until final release to manufacturing. Our engineers’ work included media path architecture, motor and sensor control algorithms, as well as structural design of the printer chassis. Additionally our engineers developed numerous tools for R&D characterization and for manufacturing quality control.

The Process

Simplexity has decades of product development experience working with HP. Not surprisingly, on the Officejet Pro X program, Simplexity engineers were fully integrated into the HP team. The Officejet Pro X development followed a rigorous process:

Core Concept Testbed

The development cycle starts with a minimally functional prototype that allows the development team to evaluate feasibility of the core invention. Only the highest risk areas are prototyped.

Engineering Model

Using rapid prototyping processes, the development team builds a prototype that includes all the important internal functionality of the product. Depending upon product complexity and functional test results several engineering models may be needed.

Product Model

Moving into the Product Model phase means that critical technology, marketing, and finance checkpoints have been met. In the Product Model units, the team builds fully integrated products using production processes like injection molding and stamped metal parts. Full performance and life tests are run, and the design is iterated until reliability goals are achieved.

Manufacturing Model

The final product development phase owned by the R&D team is Manufacturing Model. With fully tooled parts, the mechanical, electrical, and firmware teams validate fully-integrated product functions. Assembly line processes are used to build the product with direct support from the R&D engineers.

Production Release

At this point, the manufacturer fully controls the product builds. While the R&D team has largely moved on to the next program, it supports any quality or field reliability issues as top priority interrupts.

“To say that the HP Officejet Pro X Multifunction Printer is highly capable is an understatement. Its combination of fast speed, high-quality output, and excellent paper handling, … put it way out in front of the pack, even without considering its low cost per page.”

-www.pcmag.com

The Specifics

In the development of the Officejet Pro X, Simplexity:

- Engineered innovative mechanism and power train designs to reduce part count and to increase product reliability.

- Led structural design of the printer chassis. With careful attention to manufacturing process capability, the team was able to achieve precise location of critical components in the media path. Structural analysis helped us meet challenging shipping and end-user strength requirements while minimizing material costs. Designed custom R&D characterization tools. Moving paper reliably at 70 pages per minute requires a deep understanding of mechanism behavior. By working closely with HP, our test beds helped to validate sub-assembly mechanical tolerance requirements and prove that designs could meet rigorous lifecycle requirements.

- Developed custom tools for manufacturing. Getting 42,420 nozzles primed and ready to print is not an easy task. Our approach increased the testing speed by 3X compared to the original approach.

- Completed rigorous testing of critical media handling components to meet HP quality standards. Testing of lift mechanism, main tray, and pick tire detent functionality was conducted over a range of media types and environmental conditions. As a result, we achieved the lowest paper jam rates ever achieved on an ink jet product.

- Collaborated closely with the component suppliers and the Asian contract manufacturer to ensure that the design team’s detailed knowledge of product requirements did not get lost in translation.

The End Product

Our team was proud to partner with HP during the development of this flagship project which has been recognized by Guinness World Records as the world’s fastest desktop printer. Consumers get a fast, reliable, pigmented-ink color printer with low energy consumption and quiet operation.

“I have used Simplexity's design services for over eighteen years and have consistently been pleased with the high level of engineering expertise and integrity.”

-Sr. Manager, Hewlett Packard