CASE STUDY: HORIBA SURFACE ANALYZER

Designing a quality product that can meet the business and customer needs can be a risky proposition, even when a company has the engineering talent to do the work. Simplexity can leverage its experience and expertise in full-cycle product development to provide a disciplined plan and project structure to understand the challenge, thus lowering business risk for the client.

![]()

THE CHALLENGE

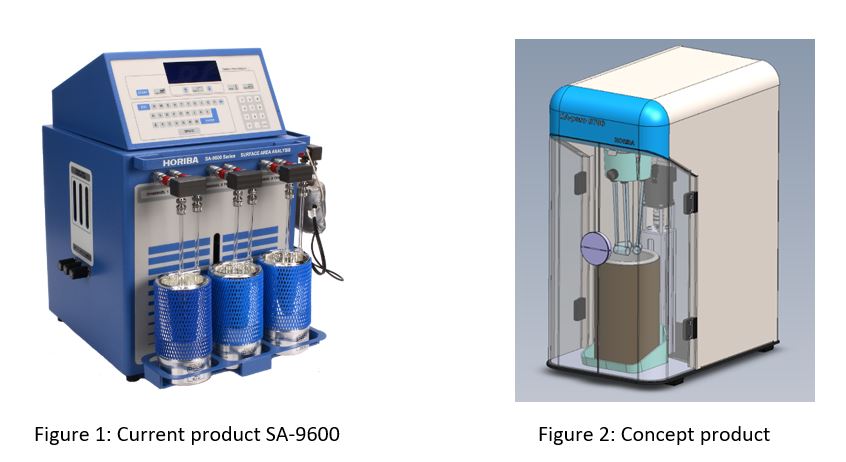

Horiba Instruments Inc. approached Simplexity with the desire to modernize the SA-9600, and older instrument used in analytical labs to measure the surface area of porous solid materials. Horiba scientists had recently developed a new core technology, but their team of engineers did not have the capability to incorporate it into a product. Horiba also needed to upgrade to the latest computer interfaces and was exploring expansion of their marketing to the biotech industry, where compliance to current FDA requirements is necessary.

THE PROCESS

A kickoff meeting began the task to move from conversations about abstract concepts and the new core technology to solid requirements. During this 10-week sprint, Simplexity extracted and validated the information needed to document and define the product engineering requirements, thus taking the first step towards creating a full project plan. With much of the technology and prior work understood, Simplexity then defined and documented the product architecture with enough detail to provide project cost, product cost, and a detailed development schedule that would result in a product ready for market.

HOW DID THE CLIENT BENEFIT?

By contracting with Simplexity to provide a detailed project plan, Horiba minimized their initial investment and risk with the assurance that the development costs and schedule had been thoroughly examined. In addition, by owning the plan documents, Horiba was not locked into a sole-source design provider or project start date. The project plan could be used by anyone at any time to run the next phase of the actual development project at the client’s discretion. Horiba could also be assured that all the details needed for program success were systematically covered in the documentation provided.

SOLUTION & RESULTS

As a result of the partnering and collaboration, Simplexity’s project manager, working with subject matter experts in mechanical, firmware, electrical, and software engineering, delivered a project plan that included the following:

- Project Management:

- Project summary slide set

- Build objectives

- Project risk assessment

- Master schedule (work breakdown structure)

- System Engineering:

- Qualification test plan

- Electrical Engineering:

- System diagram

- PCA block diagram

- Mechanical Engineering:

- Costed BOM

- Engineering reference specification

- Mechanical layout

- Mechanical development plan

- Firmware Engineering:

- Firmware development plan

- Software Engineering:

- Software architecture diagram

- Software development plan

Thanks to excellent communication throughout the sprint, the customized plan and project structure that Simplexity presented was exactly what Horiba needed to evaluate the business case prior to deciding on their next steps.