Precision temperature control in product design is a matter of degrees. Sometimes the Goldilocks zone is as broad as a barn door. When it is, life is easy. Sometimes though, you need pinpoint accuracy, which makes things more interesting. But when you need to maintain a sample at +/- 1 °C, it helps to find a product development partner with experience in getting to a specific temperature and staying there.

Precise temperature control is important for many manufacturing, analysis, and diagnostic processes. Minimizing rise time is also key. When time is money, throughput is the bank. Simplexity Product Development understands the engineering and economics of thermal processes.

Thermal control system basics

Thermal control systems usually consist of four components: a heat source, a heat spreader, a temperature sensor, and a controller. Sometimes we combine components; the heater can also be used as the temperature sensor, and the sensor can be considered part of the controller. But in one form or another, those components all need to be there. The trick is putting them together to get maximum performance, minimum cost, and the shortest possible lead time.

That’s what you get from a partner who knows thermal control systems. A simplified and anonymized example of a Simplexity tool developed for one of our customers can illustrate these principles.

An example of a thermal control tool

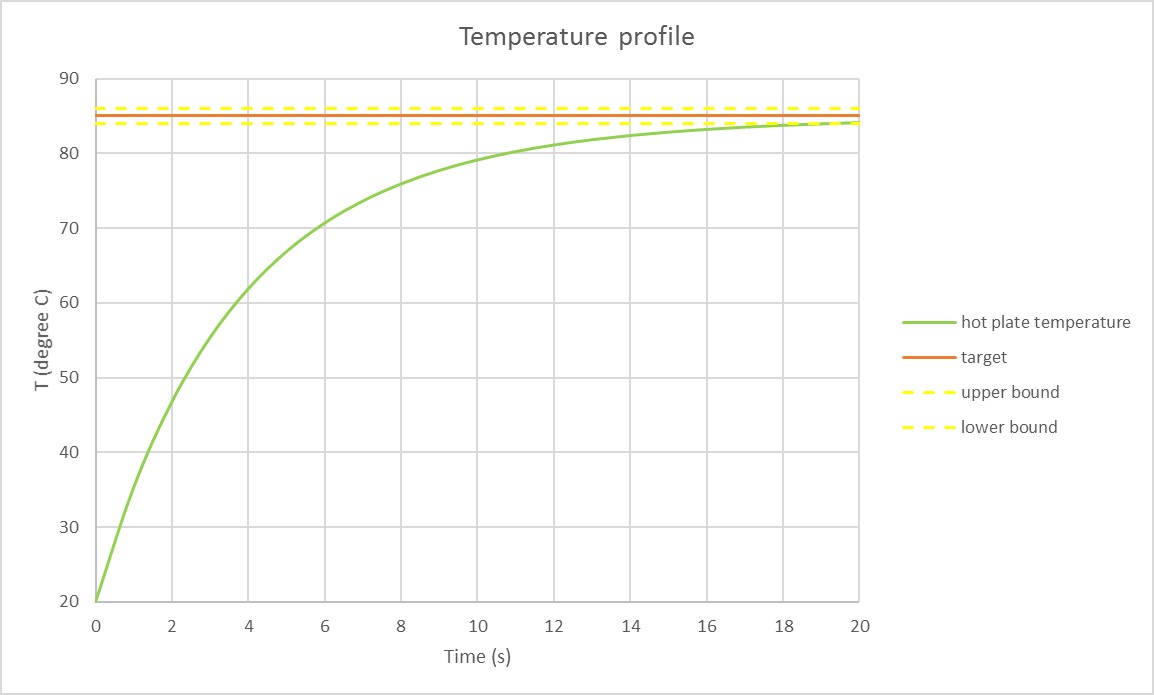

Simplexity was asked to develop tooling to process a 300 mm Silicon wafer for dicing into medical diagnostic chips. The wafer had to be held at 85 +/- 1 °C for several minutes. Molarity of the organo-phosphate solution, temperature, and time were the critical parameters for getting the coating right. A simplified version of the components is used here to illustrate precise thermal control.

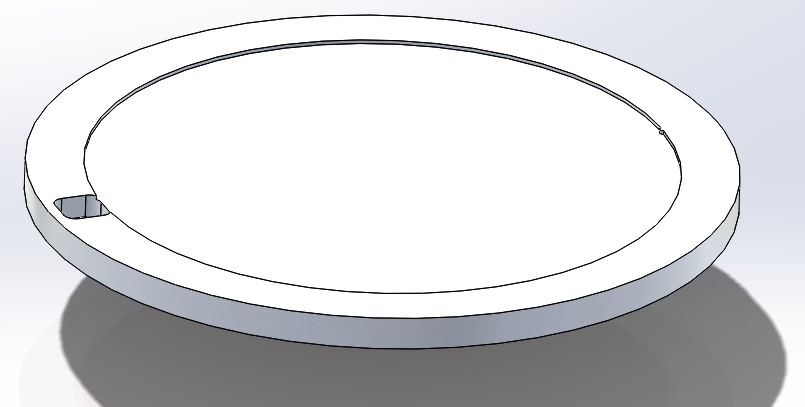

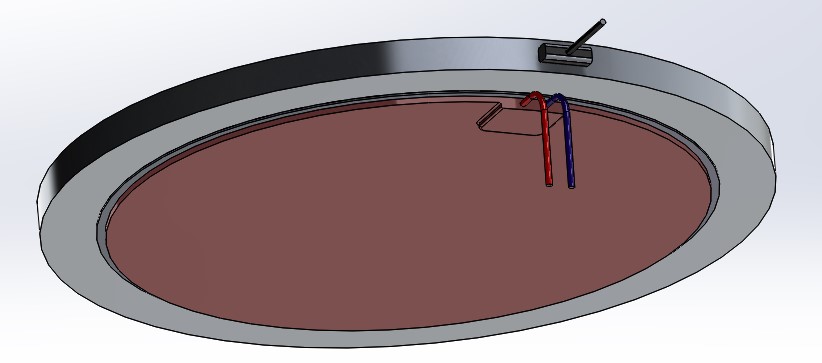

(Top) A heat spreader made from anodized aluminum. Aluminum provides high thermal conductivity; anodization provides corrosion resistance. The wafer is nested on the top surface. (Bottom) Bottom view of the heat spreader shows the 1000 W film heater and a type-K thermocouple used for temperature feedback. Together with a PID temperature controller, these are the components of a precision thermal regulation system.

Using a 12-inch film heater makes it a lot easier to get uniform temperatures together with a fast rise time. Using a cartridge heater is also an option, but then the heat source is more concentrated, which can result in hot spots. Using a thicker heat spreader mitigates temperature variation, but it also creates greater thermal mass and longer rise times.

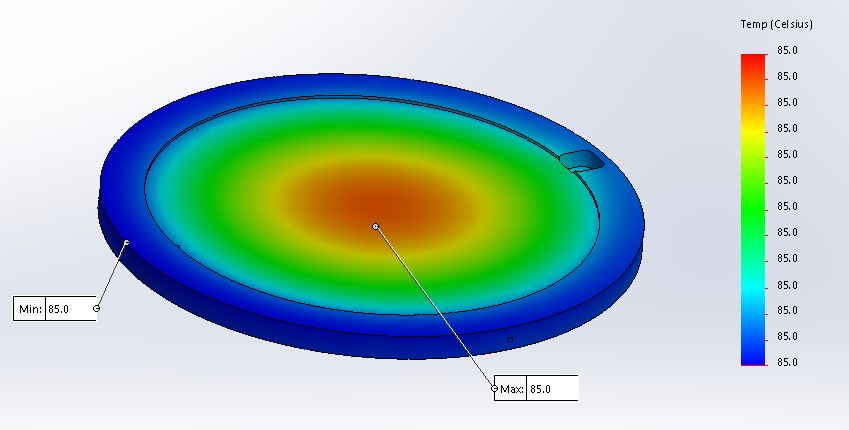

Steady-state thermal model of temperature distribution in heat spreader. Variation is less than 0.1 °C on the surface of the wafer nest, due to the conductivity of the plate and the distributed heat source.

The 85 +/- 1 °C temperature spec applies over the entire surface of the wafer nest. A small part of the error budget is consumed by variation within the heat spreader, but other error sources are more significant. The type-K thermocouple is cheap and readily available and has an accuracy of 0.4 °C. Getting accurate temperature feedback is a bigger problem than uniformity, but perfect is the enemy of good enough. Within the constraints of time and budget, +/-0 .4 °C accuracy worked very well.

Insulation is also a source of temperature variation. The schematic fixture shown above omits insulation, but it’s critical. Heat flow leads to temperature gradients, and gradients are the enemy of uniformity. The actual fixture had solid insulation under the spreader and around the edges, with a lid on top to limit heat loss.

Other factors in thermal control

Another factor mentioned only in passing is rise time. Normally we think of it in terms of throughput, but for this system a more significant factor was control of fluid bath exposure time.

Wafer nest temperature profile. With a 1000 W heater, it takes 15 seconds to reach 84 °C.

To get faster rise time, we can either use a more powerful heater or a thinner heat spreader. For low-volume production tools, custom components (like film heaters) are not only more costly, but a supply risk if replacements are needed. Sometimes it’s worth it, but for this application, a 19 second rise time was quite sufficient, and an OTS (off-the-shelf) heater was ideal.

A thinner heat spreader is the other option, but warpage becomes a risk with thinner parts. Flatness of the heat spreader is also a critical parameter for uniform wafer temperature. The spreader can have beautiful uniformity in temperature, but if it isn’t flat, the wafer sees variations in contact resistance that creates cold spots where it matters: on the top surface of the wafer.

Fabrication experience can make all the difference. It’s important to use stress-relieved aluminum for the heat spreader, because material with internal residual stresses can warp after machining. K100S aluminum is very stable, even after asymmetric machining, preferred when flatness is critical.

It helps that the contact is wet – and it’s essential to prevent air pockets in the contact film – but we still need to use an optical IR thermometer for verification.

After processing chemistry is complete, a rinse cycle uses deionized water to clean the wafer and flush the process reagents. After that, the lid is opened, the wafer is removed, and a fresh wafer is inserted. It’s a sensitive process, and a valuable component. For a part of this nature, process failures due to poor thermal control are inexcusable, thus choosing the right product development partner is essential.

For more on topics related to product design and testing, follow Simplexity’s product development blog or connect with us on LinkedIn.

For any questions related to thermal control systems or any other topics, please contact us at info@simplexitypd.com.