If you are developing a medical device, knowing which testing standard will be used to evaluate the safety and effectiveness of your device is critical for obtaining FDA clearance or approval. It is most efficient to start planning for it during the early phases of your product development journey. The IEC 60601 standard is widely used and is recognized in many countries around the world. In addition to understanding the standard, there are various options for the types of testing and pre-tests that can be performed to give the device the best chance at passing the final test and receiving certification.

What is the IEC 60601 testing standard at a high level?

Medical devices approved in most of the world require certified testing against 60601-1 Medical Electrical Equipment – Part 1: General requirements for basic safety and essential performance and the related standards. In addition to the base standard which will always apply, there are Particular Standards and Collaterals Standards.

The numbering scheme is intended to help keep it straight:

- Base Standard 60601-1

- Note there is no 3rd set of numbers after the “-1”

- Particular Standards: These apply to specific devices. Examples include: ventilators, glucose monitors…

- Number Format: 60601-2-X

- Collateral Standards: These are broad based performance requirements and one or more may apply to your device

- Number Format: 60601-1-X

Which particular and collateral standards apply to your device can be a challenge to determine. We recommend consulting with a regulatory expert to help make that decision because it is very device-specific.

In general, most Class 2 medical devices, at a minimum, will need to go through:

- 60601–1 Basic Safety,

- 60601-1-2 Electrical Safety (EMC/EMI).

What type of IEC 60601 testing / level makes sense when?

For FDA approval you will need to get a certified report from one of several certified test agencies. Examples of certified safety agencies include TUV, Intertech, BSI, and other agencies. However, you don’t need a certified report throughout the entire product development cycle. Sometimes it makes more sense to pre-test in-house or rent equipment for dry runs. So, the question becomes, when to do the IEC 60601 testing in-house and when to pay to use the agency’s equipment?

When does it make the most sense to test or pre-test in-house?

It makes the most sense to test or pre-test in-house when it is easy to create a realistic version of the test or if you already own the equipment needed. For example, if your company already owns a temperature / humidity chamber, it is best to do preliminary tests in-house to gain confidence that you are likely to pass the first time at the test house.

Drop testing is another test that is easy to pre-test in-house. Generally speaking, it is easily created using measuring equipment and simply dropping the device to onto a concrete floor from specific heights (or whatever the most applicable use case would be for your device). It is also valuable to video record each time the unit is dropped, so the video footage can be compared with the post-drop inspection results. A big advantage of doing drop testing in house is that if your initial testing goes awry, it is much faster to replace components or rework a unit in your own office rather than trying to do it at an outside testing location. You can work out the kinks faster if the drop results indicate that there could be a problem.

What about when to test at the test house?

It is best to test at an outside test house when the equipment needed for testing is very specialized, nuanced, or expensive.

If the equipment is nuanced, such as with most water ingress test fixtures, having the test expert available will give you some great insights into the problems you may see. Test experts have likely seen a lot of ingress failures & solutions before. I also have found that it is not worth the time to build an in-house water ingress test. Getting the test fixture right is harder than it seems and can become its own design project. The only exception to that might be immersion testing, as holding a unit underwater is pretty straightforward.

Also note that just because a product passes a “higher” IP rating, that does not mean it will pass a “lower” IP number. If a product passes IPX7 (immersion up to 1m), that does not mean it will pass IPX5 (water jets).

It is also best to test at an outside test house if you need expensive equipment. For example, if the test house already owns the altitude chamber you have had your eye on, then it is likely much more cost effective to rent time at the test house. Additionally, the test house cost usually includes the time for the test house staff to support testing, so you would have an expert on hand to help set up the testing and troubleshoot test tool errors.

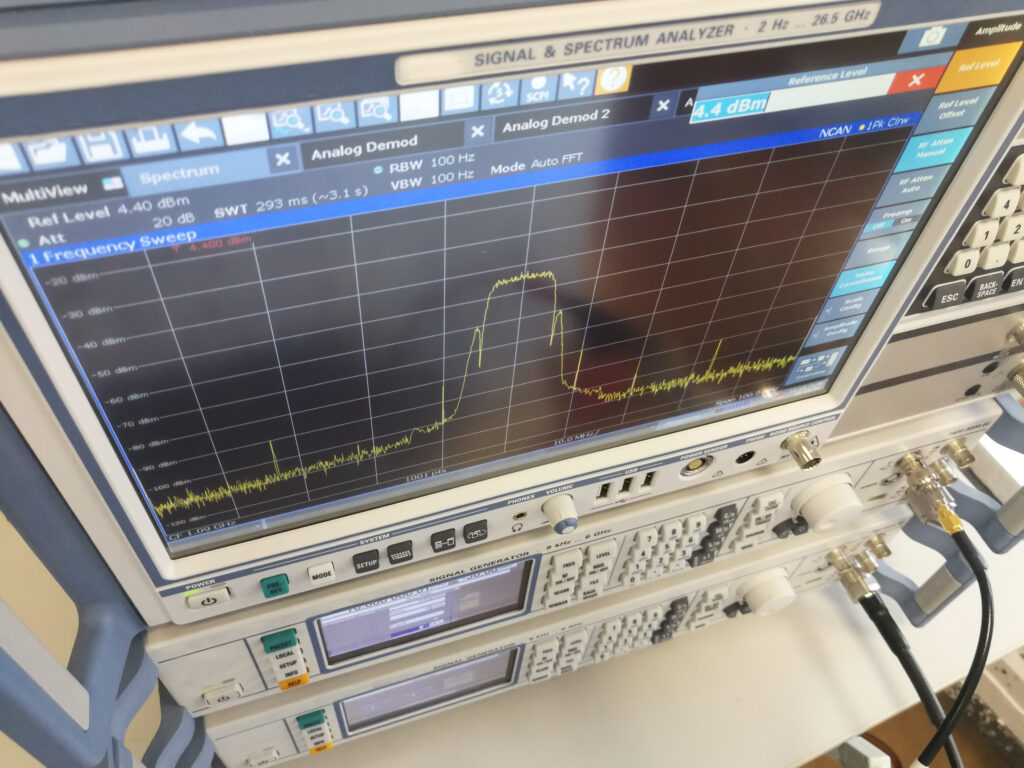

It is critical to do preliminary EMC (Electromagnetic Compliance) / EMI (Electromagnetic Interference) testing of any device that contains custom electronics, which requires equipment that is expensive and test chambers that are physically very large. If there is a problem with EMC, often the resolution requires modifying the design and releasing it again for fabrication, called a board spin. It is better to do a board spin when you are still developing and not right before you are hoping to submit a device for approval, so early testing is used to find and resolve issues.

A test house can be used in a number of ways:

1) Renting time on the test equipment – paying for hourly rental of their equipment and chambers. Keep in mind that you can use this rental time to do testing to meet your own product requirements or to do preliminary tests to build confidence that your design will pass high risk 60601 tests before there is an official report.

2) Complete dry run or preliminary testing and reports – paying for test time at a test house, which typically includes an operator’s time to help set up the equipment and run the tests per the appropriate standard but without the certification. You may want to do this in situations where you have prototypes and you have another round of design updates. This can inform problems in your design before they are showstoppers.

3) Receiving full certified reports – after a product has been tested and found to meet IEC 60601 standards, the safety agency or compliance test house can issue a certification or approval. This testing must be done on production-equivalent devices to ensure that the device is representative of the device that will be used by the end-user.

Overall, the IEC 60601 testing standard is designed to ensure that medical electrical equipment is safe and performs as intended. By complying with the standard, manufacturers can help protect the safety of patients and healthcare professionals, as well as ensure that their products meet regulatory requirements around the world.