Full system product development refers to the ability to design an entire product. This can include mechanical, electrical, firmware, algorithm and control systems, and, when transferring to manufacturing, quality engineering and NPI (New Product Introduction) as well.

Today’s complex designs almost always include the need for multi-disciplinary engineering development. Not all partners can support full system development, so let’s dig into some of the advantages of enlisting a full system product development design partner who can.

Advantages of Working with a Full System Development Partner:

Efficiency

There are inherent efficiencies in having a product developed by a highly integrated, cross-disciplinary team at a single design partner. The key is partnering with a design firm, like Simplexity, that can support the different engineering disciplines WELL.

Design Integrity

With a focus on creating the best, most simplified design possible to meet requirements, a design partner’s ability to complete design engineering in a single, highly integrated shop often ensures optimal design quality and design integrity since all the subsystems are designed to work together well, in a coordinated and concerted manner.

Requirements Management

It is quite common as design engineering progresses for various requirements on a design to be in conflict with one another. When trade-offs must be considered or reconsidered based on the product’s prioritized functional requirements, having all engineering within a single, integrated design partner can streamline this process to keep the project schedule and costs in check.

Cost Reduction

When a single product development partner can cross engineering disciplines, cost-reducing design options can present themselves that could be missed in a more siloed engineering approach at multiple development partners. This more integrated approach to design can often result in design simplification and lower product costs.

Cross-Project Acumen and Enhanced Problem Solving

Often the solution to a project’s stickiest design challenge in one subsystem can come from leveraging a design solution change in another subsystem. For instance, a full system development partner is more likely to have this broader base of experience across their integrated teams and can often offer surprisingly effective solutions that may not be immediately apparent if following a more siloed engineering approach with multiple design partners.

Design for Manufacturability without Production Bias

A design partner with teams devoted to design engineering and with NPI manufacturability chops, is well positioned to provide efficiencies from prototype all the way through to production handoff to the contract manufacturer (CM). When design and manufacturing are conflated into a single Contract Design Manufacturer (CDM), there are hard costs built in to manufacturing lines and production process. These biases can potentially limit design choices the CDM is willing to consider along the way. A separation of specialties ensures you get the best of both worlds.

Design Optimized Based on Eventual Production Volume

Careful production volume cost analysis can greatly inform design choices. By keeping design with a single full system development partner, designs can be optimized to accommodate either custom/precision low volume production or low-cost, high-volume production at the lowest possible cost while being manufactured and assembled to the highest possible quality standards.

Accountability and Functionality

Ultimately, the product must work. By having development completed by a single, full system product development partner, they are solely responsible for and accountable to delivering a fully functioning product as defined by project requirements with all subsystems working well together vs. delivering a sub-set of code or parts that must be integrated across multiple partners.

Quality and Manufacturability

By enlisting a development partner that includes quality engineering and NPI teams, not only are manufacturing considerations baked in early (when course corrections are the least expensive to fix) but you also have the added benefit of in-house test tool development to support manufacturing and assembly processes and product quality verification. Additional services in this space can include CM selection and onboarding, tooling vendor selection, quality metrics verification, process validation and even onsite build and test supervision.

Ability to Salvage “Problem” Projects

Design engineering mis-starts are not uncommon. Perhaps a project is started with an underqualified CDM or design firm, or development needs changed mid-flight that outmatch early partners. In these cases, a full system development partner can often offer a much needed “safety net” to address holistically whatever is holding a project hostage. This saves the client from having to figure out all the pieces of the puzzle with different development partners and, most likely, renders a more successful, better designed, more cost-effective result.

What Role do Systems Engineers Play in Full System Development?

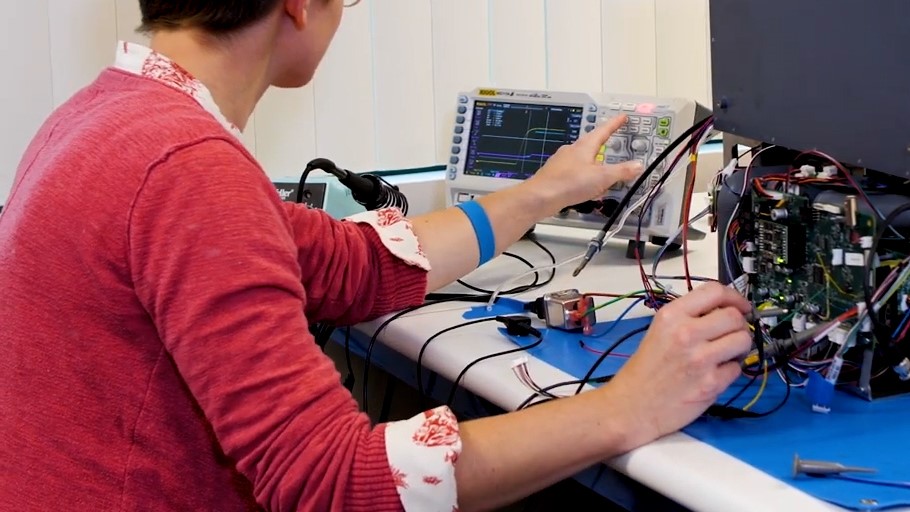

The role of a Systems Engineer (SE) is to integrate the work of the other engineering disciplines so that the full system design works well when assembled. The higher the level of interaction between the different subsystems, the more important the role of the SE. For instance, many products are simply electronics in a box. Think of a WiFi router. It’s a complex product, but there is very little interaction between the mechanics (a box) and the electronics. There is a LOT of integration between the firmware and the electronics. However, the EE/FW interactions are very common, and usually don’t need an SE. Now, think about a 3D printer. Lots of moving parts. There’s electrical power needed to run motors, sensors to read, and FW algorithms required to make it all move. This is a highly integrated ME/EE/FW project, and where the SE plays an important role bringing all of those pieces together to work well. Simplexity proudly includes a team of top-notch Systems Engineers in our Design Engineering teams.

New Matter 3D printer that Simplexity helped design

What Services Should a Full System Development Partner Offer?

As noted, not all design partners are created equal. When evaluating partners make sure to confirm the types of engineering and product development services they can support. Services a typical full system product development partner should offer, include:

Exploration, Requirements and Planning, Architecture and Technology Feasibility

- Research

- Architecture exploration & development

- Feasibility studies

- Competitive product analysis

- Manufacturing strategy identification

Prototype Design, Build and Test

- Prototype design, build and test

- Product simplification/cost reduction

- DfM and DfX Evaluations

- Detailed product design

- Design for high volume production

- CM selection and onboarding

- Tooling vendor selection

Design Verification and Transfer

Production

- Manufacturing design guidance and ongoing engineering support

- Ongoing quality metrics monitoring and optimization

Consult a Development Partner as Early as Possible

It’s important to consult with a development partner as early in product ideation as possible, even for just initial consultation before funding is secured. While a temptation may exist to only enlist support for the portions of the design your team can’t develop in-house once the project is under way, it can end up saving cost and schedule if you reach out to a full system development partner first before progressing too far into design. This step can also provide confirmation that development timelines are aligned to map to eventual manufacturing launch plans.

A potential concern may be the impact on total project cost going with an outsourced, full system partner. Will a full system development partner drive up the costs of the project? What you may find is that the converse is true. By leveraging all the advantages listed above, you may actually end up with a more cost and time-efficient path to project completion that results in a higher quality, more manufacturable product in the end.

Further, a design partner like Simplexity employs a Phase Gate Development Process where projects can be logically broken into design phases and billed accordingly. So, clients are only committed to costs associated with each phase before moving on to subsequent phases. This provides a higher level of security and control for clients and makes it easier to engage early and develop trust throughout the product development process without committing too much, too soon.