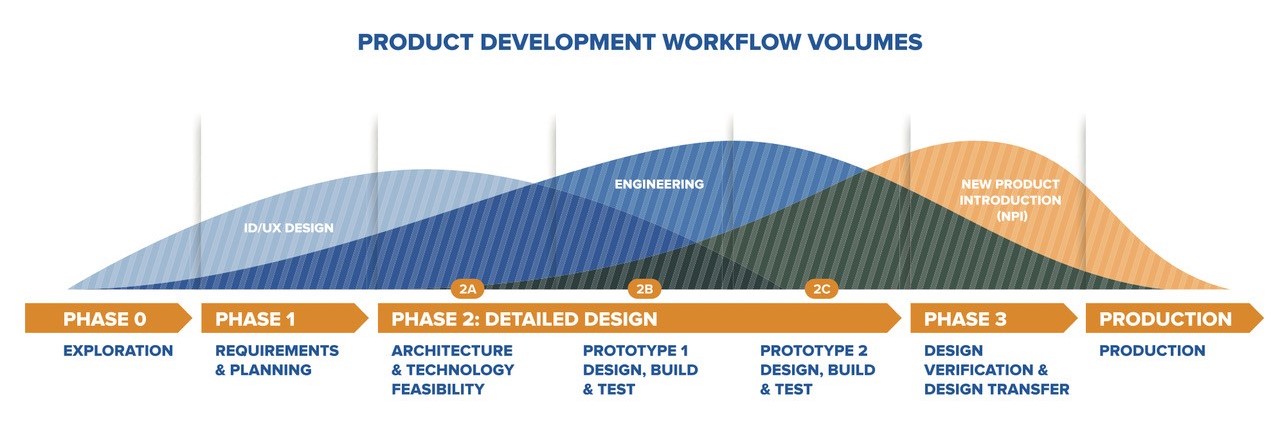

NPI incorporates planning, engineering collaboration, product verification, and manufacturing readiness into a coordinated new product development plan. NPI activities and deliverables are listed below in Phase order according to typical design engineering workflow shown above.

TYPICAL NEW PRODUCT INTRODUCTION (NPI) DELIVERABLES INCLUDE:

PHASE 1: REQUIREMENTS AND PLANNING

- Manufacturing strategy requirements document

PHASE 2A: ARCHITECTURE AND TECHNOLOGY FEASABILITY

- Manufacturing processes review

- Product requirements review

- Critical Performance Metrics (CPM) specifications review

- Project build plan

- Manufacturing plan

- Supply chain strategy development

PHASE 2B: PROTOTYPE 1 – DESIGN, BUILD AND TEST

- ADD Cost of Goods Sold (COGS) worksheet

- RACI chart

- Subassembly strategy development

- Process flow documents

- Test plans and reports

- DFMEA analysis

- Tolerance analysis

- Vendor selection

- Contract manufacturer quote package and selection

- Tooling schedule

- DfX reports (for manufacturability, assembly, serviceability)

PHASE 2C: PROTOTYPE 2 - DESIGN, BUILD AND TEST

- FAI and first article reports

- Quality assurance plan

- Design Transfer package preparation

- Work instructions

- Build status reports

- Build unit tracking

- Assembly fixture and QC tool development

- Contract manufacturer onboarding

- Manufacturing release package delivery

PHASE 3: DESIGN VERIFICATION AND DESIGN TRANSFER

- Root Cause Analysis (RCA)/Defect resolution

- Vendor Management

- Unit build tracking

- Quality metrics verification

- Process validation

- Reliability testing

- Regulatory certification

PRODUCTION

- Manufacturing guidance and ongoing engineering support

- Ongoing quality metrics monitoring and optimization

NEW PRODUCT INTRODUCTION PHASES:

Contact Simplexity to discuss how our New Product Introduction (NPI) team can help you get your next innovation to market.