CASE STUDY: OPULUS LUXURY SKINCARE DEVICE

Featured as one of The Best Inventions in 2021 | Time Magazine

![]()

THE CHALLENGE

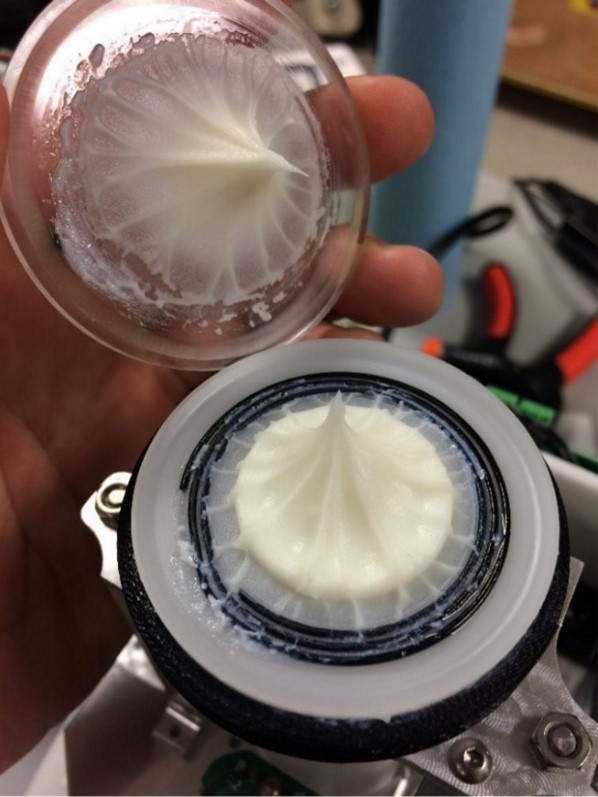

Opulus Beauty Labs, founded by Dr. Robb Akridge, who is known for founding the highly successful Clarisonic facial cleansing brush, has invented a new product. This product revolutionizes the skin care industry by delivering freshly activated and customized beauty treatments on demand to the consumer. The idea is to provide a handheld device which accepts single use skincare capsules with waxy outer shells and active ingredients stored separately inside. The capsule, or OpouleTM, is placed inside of the device, the lid is closed, the device is activated, and 30 seconds later the consumer has warm, freshly mixed product ready to be applied. The single use OpouleTM design is intended to maximize the effectiveness of the active ingredients by only activating them just prior to application. The truth is that most creams and lotions sit on the shelves in warehouses and retailers for months before use. Active ingredients lose potency in that time. Creating the OpouleTM with the active ingredients isolated from the rest of the cream preserves the potency of the actives.

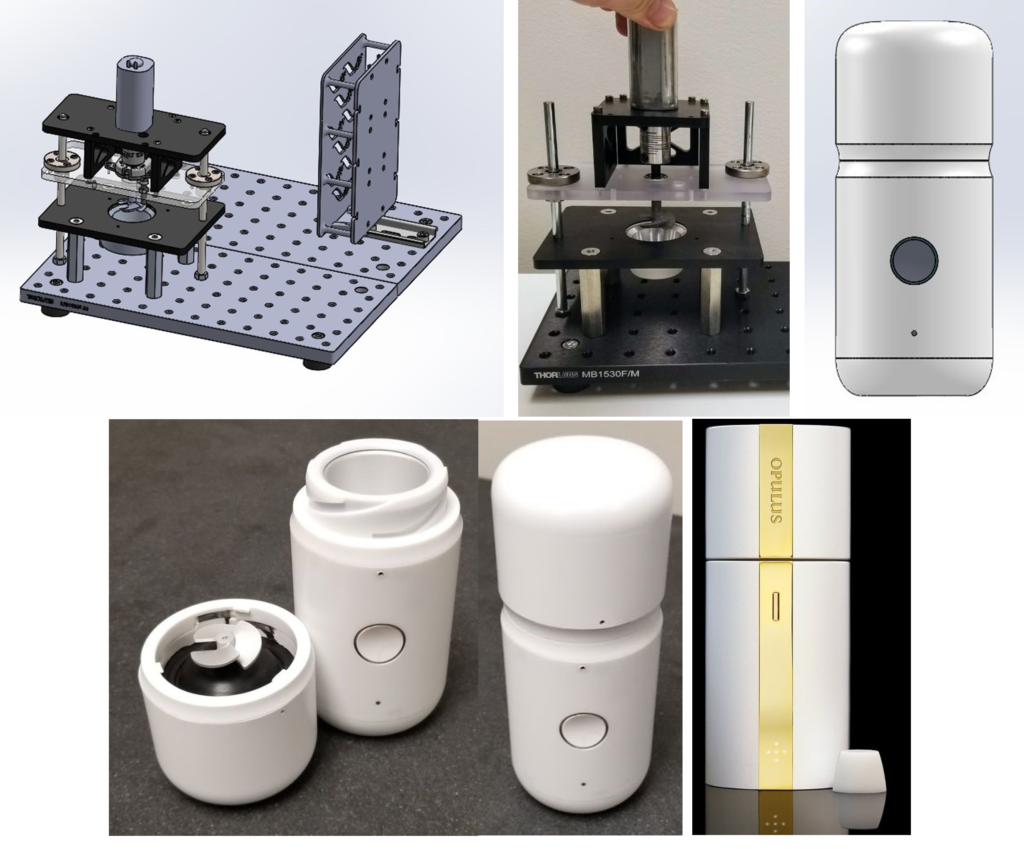

The device itself needed to look elegant on a bathroom counter while also being portable enough to take on an extended vacation. It also had to meet rigorous requirements of mixing and heating time. The appliance would need to mix, warm, and present to the user cosmetic creams on demand. The device had to behave as if it were magic and complete its cycle in moments.

Opulus Beauty Labs approached Simplexity to engineer the device and work in partnership with the industrial design (ID) firm Tactile. The heating and mixing process had been shown to work in laboratory settings with hand-held mixers and off-the-shelf heating pads but transferring these conditions into a handheld, battery powered luxury device presented many challenges.

THE SOLUTION

The first step in the process was to gather requirements. Several meetings took place with the client and the ID firm to discuss how the device fits into the user’s lives. Mixing time, target temperatures, and user interactions were established. One of the hardest requirements to meet was making it easy for the user to access the mixed cream.

Next, the team brainstormed and researched techniques for creating that magical experience desired. The brainstorm generated many ideas about what types of mixers could be used. Simplexity benchmarked many different existing mixing and mechanical processing technologies. These included centrifugal mixers, burr grinders, taffy stretchers, eggbeaters, paddle blenders, rolling mills, dough hooks, concentric pistons, and ultrasonic mixers. These existing technologies were evaluated and compared. It became apparent that processing the thick, thixotropic cosmetic materials in small batches was going to be a big challenge. The tendency of the cosmetics to melt during heating added to the complexity and difficulty in mixing.

Several concepts emerged from the brainstorming and research as most likely to be successful. Crude proof-of-concept prototypes were built for each of these concepts, and performance analyzed.

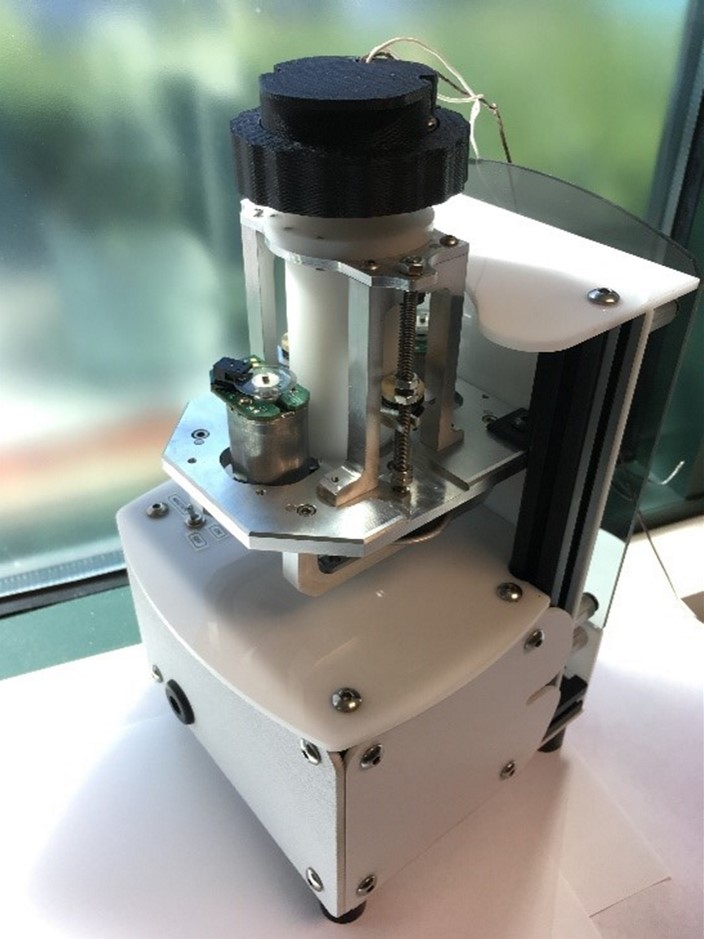

Simplexity engineers designed and engineered the device from the ground up to match the client’s vison and to fit within the industrial design constraints. Prototypes were created to match laboratory experiment conditions while maintaining the client’s desired form factor, battery life, and many other features.

MECHANICAL ENGINEERING

Simplexity was tasked with designing a method for heating and mixing the OpulusTM. We gathered all the input criteria from the benchtop testing and designed a device to provide the required heat to adequately melt the OpouleTM without damaging it or raising a user safety concern. This included selecting the heating element and sizing the motor accordingly. We worked with heater manufacturers to design and build a custom heater that met the heat flux requirements, had temperature sensing, and an over-temperature safety cut-off switch all embedded within the heater assembly.

An initial breadboard unit was designed so the client could vary the processing parameters to refine the formulations of the OpouleTM. This breadboard enabled investigation of possible cosmetics, user interactions, and appliance size, cost, appearance, and many other factors critical to product development.

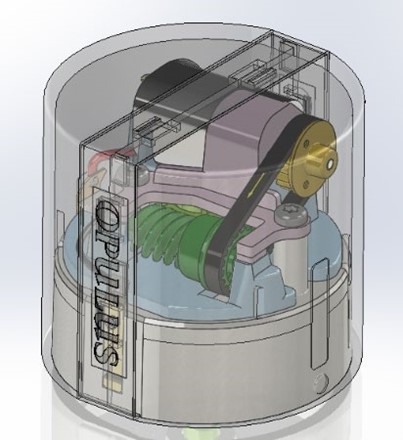

Development of the product went through three prototype designs in which clever injection molding design reduced costs while inventive design lowered the number of components and shrunk the overall system size to meet the client’s design intent. Appropriate materials were chosen to not degrade with the harsh chemicals found in most bathrooms and the components within the OpulusTM themselves as well as meet the cosmetic requests of the ID team. To protect the device, the product was designed to meet the IP56 liquid and dust penetration resistance and 1-meter drop resilience onto a hard floor. The final result was a sleek looking, handheld device capable of gently heating and mixing OpulusTM to be presented to the consumer.

ELECTRICAL ENGINEERING

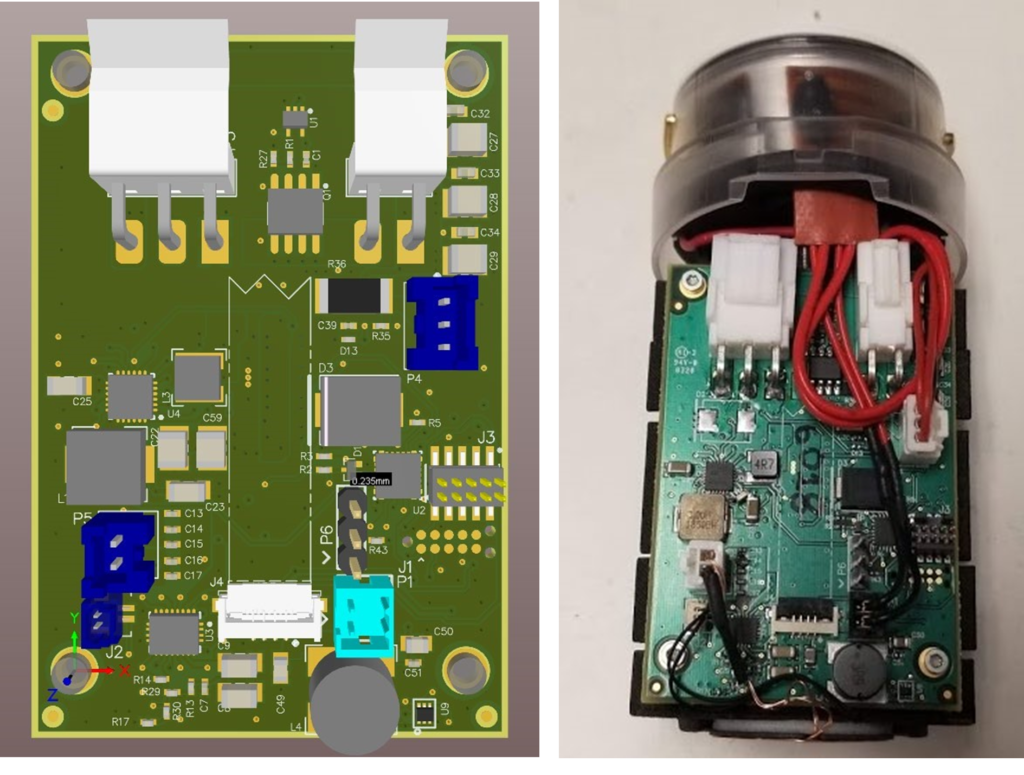

Simplexity’s electrical engineers designed the electronics inside of the device. Working closely with the mechanical engineering team, we were able to shrink the printed circuit board assemblies (PCBAs) inside of the device while still providing provisions for the client to alter the embedded firmware for later development. Another requirement for this device was that it needed to be wirelessly charged using the Qi charging technology. We built custom diagnostic hardware to analyze and adjust the wireless charging properties of the device. This allowed the device to “handshake” with off-the-shelf wireless charging pads and optimize the charging system to properly charge the custom battery pack.

Opulus Beauty Labs decided that they wanted to involve the contract manufacturer’s (CM) electrical design team as soon as possible. While our engineers selected components and designed the PCBA schematic we also worked closely with the CM who was in charge of the PCBA layout and fabrication. This collaboration allowed for a quick turnaround of custom PCBAs built by the intended supply chain.

FIRMWARE ENGINEERING

The Simplexity Firmware team started with the goals to minimize cost and maximize flexibility where required to support tuning and process development. After gathering functional requirements, the team then estimated the RAM and FLASH memory requirements for the Firmware. The Firmware and Electrical engineers then selected a low-cost Microcontroller Unit (MCU) that met those requirements with a reasonable margin. With an MCU selected, the Firmware team then used vendor-supplied tools to generate the MCU initialization code. This initialization code enabled us to get initial code up and running very quickly to test the initial circuit boards and validate the RAM and FLASH estimates.

For the higher-level firmware architecture, we anticipated the need for flexibility to support the process flows so that the client could experiment with different OpouleTM process parameters. Additionally, from experience, we knew that the user interface (UI) was likely to change throughout development based on user experience and system function. To support this, we modeled the system behavior in a state machine and parameterized factors such as LED blink speeds, temperatures, and motor speeds and stored them in non-volatile memory. By adding a serial port component and a command parser, we enabled rapid experimentation and testing by allowing the parameterized factors to be edited without the need to recompile code or reflash the firmware. In addition to parameter tuning, the command parser allowed the extraction of performance data for external analysis. With this overall design approach, we were able to make significant and focused changes to the system behavior quickly with minimal introduction of defects which led to efficient iteration to meet client needs.

To maintain code quality, continuous integration and code release processes were put in place early to regularly monitor unit test coverage, RAM and FLASH usage, and overall code repository health. Regularly scheduled and well documented firmware releases helped isolate our engineering partners and clients from normal churn of development.

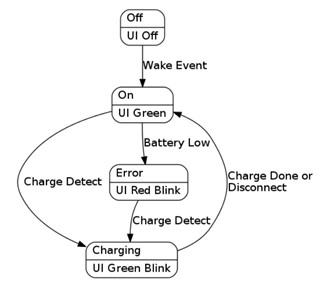

State machines were created for each major area of functionality. For example, battery LED performance was outlined using the following state machine:

SYSTEMS ENGINEERING

The systems engineering effort on the project included:

- An optimized mixer drive system utilizing a standard low-cost DC motor with a customized winding resistance selected by Simplexity. Coupled with a drive train gear ratio specifically designed to work with the motor to meet the speed and torque requirements within a tight space constraint. Gear tooth profiles were optimized using Simplexity’s proprietary gear design and analysis tool set.

- Mixer speed control without rotational speed feedback was achieved using a velocity observer-based control system. With this system, only a power and ground contact were required between the base, which housed the battery and drive electronics, and the lid.

- Custom heater servo control with optimized temperature profile to minimize heater warmup time and temperature overshoot.

THE RESULTS

With the Opulus Beauty Labs system, say goodbye to plastic bottles full of old creams sitting on the shelf. Transform your beauty routine by selecting the best OpouleTM formulation for your skin type and popping it into the Activator when you’re ready to apply a cream. The active ingredients will be mixed together on demand for the most potent effects, leaving you with soft and luxurious skin. Not only is this approach better for your skin, but it’s also better for the environment, eliminating tons of plastic and single-use container waste.

The final product: The activator, lid, and a few OpoulesTM, each with a different formulation

RESOURCES

Opulus Beauty Labs: https://opulusbeautylabs.com

Time | The Best Inventions of 2021: https://time.com/collection/best-inventions-2021/6114370/opulus-beauty-labs-system/

The industrial design firm, Tactile, describes more of the user experience portion of Opulus Beauty Labs: https://tactileinc.com/work/opulus-beauty-labs/