During product development, you must take risks to achieve market success. To also achieve business success, it’s critical for a design firm to assess and address risks as early and affordably as possible. At Simplexity, we’ve spent our careers helping a wide variety of companies do just that, and view product design risk mitigation as an integral part of the stages of product development.

Why is product development risky?

For a product to have market appeal, it must either be differentiated from existing products in its category, or it must create an entirely new category. In either case, the successful product offers something new to the market. That “something new” requires a design that’s never been done before. And if it’s never been done before, it’s inherently risky.

The more customer “wow” you pack into your product, the greater the risk in the product development process. The upside is that it will also bring higher potential for market success. If you take no risk with your product, the chances of success are low, thus mapping the risk/reward space is a helpful component of brainstorming.

Product development risk categories

Just like any business, product development has many types of risk. There are market-based risks such as commercial viability, consumer acceptance, competitors, and the product introduction window timing. There are organizational risks like availability of funding, availability of management sponsorship, staff loading, and capability of project management. There are risks associated with building your product, including the technical and logistical capabilities of your supply chain and manufacturing partners, as well as the business stability of each.

At Simplexity, we believe that the product design team must be heavily involved with the selection, assessment, and interactions with supply chain and manufacturing partners during development. However, I’m going to focus on the different areas of technical risk in the design portion of product development.

Technical risk centers around what is both technically possible and financially feasible for the product and its market segment. A successful design team must find a way to answer yes to both “Can we do it?” and “Can we afford to do it at our price point?” Developing new product features that meet the required specifications, technicality, and quality, with a viable cost structure, is the overarching risk for an engineering design team.

Mapping and weighing risk assessment

The classic tool for the assessment of technical risk of a product is the failure modes and effects analysis (FMEA). Essentially, one looks at a product, assesses all the different ways the product can fail, and the effects of those failures on the product, the customer, and the manufacturer. When applied in the design phase of product development, we add a “D” to front of the acronym, and perform the analysis on the design options under consideration.

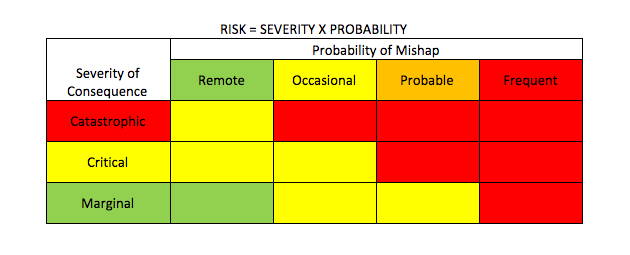

At Simplexity, the DFMEA process involves getting a broad team to do a design review. It’s important to get fresh eyes on the design, and bring in a broad experience base. After the team has conducted their individual design reviews, we conduct a brainstorming session to list all the design’s potential failure modes. We then assess each item in the list for both the probability of the given failure mode and the severity of consequence of that type of failure. Finally, we map those assessments to a risk category with this matrix:

From this mapping, we can sort the failure modes by risk category and prioritize our mitigation efforts accordingly. Note that we do not apply weightings to these categories and attempt to generate a numerical risk value. This is intentional. Over the years, we’ve found that applying weightings just shifts the debate over the categorization to a debate over the weighting of the category, doing nothing to move the analysis forward. Our DFMEA process has proven itself to strike the proper balance between effort (and cost) expended, and value provided.

For more information on risk mitigation, check out the second part of our Risk Mitigation in Product Design blog!